9-14 Application Notes Rexroth IndraDyn A

Before startup and during operation specifications, the brake function

must be tested with the ”brake command” function. By applying a small

amount of motor torque, the brake is checked for slippage. Additional

information and specifications of this function may be found in the

ECODRIVE firmware functional descriptions.

Selecting Holding Brakes

Brakes are either electrically-clamped or electrically-released. Due to

functional differences, different brakes should be used for main-spindle

and for servo-axes. Observe the safety requirements during the system

design.

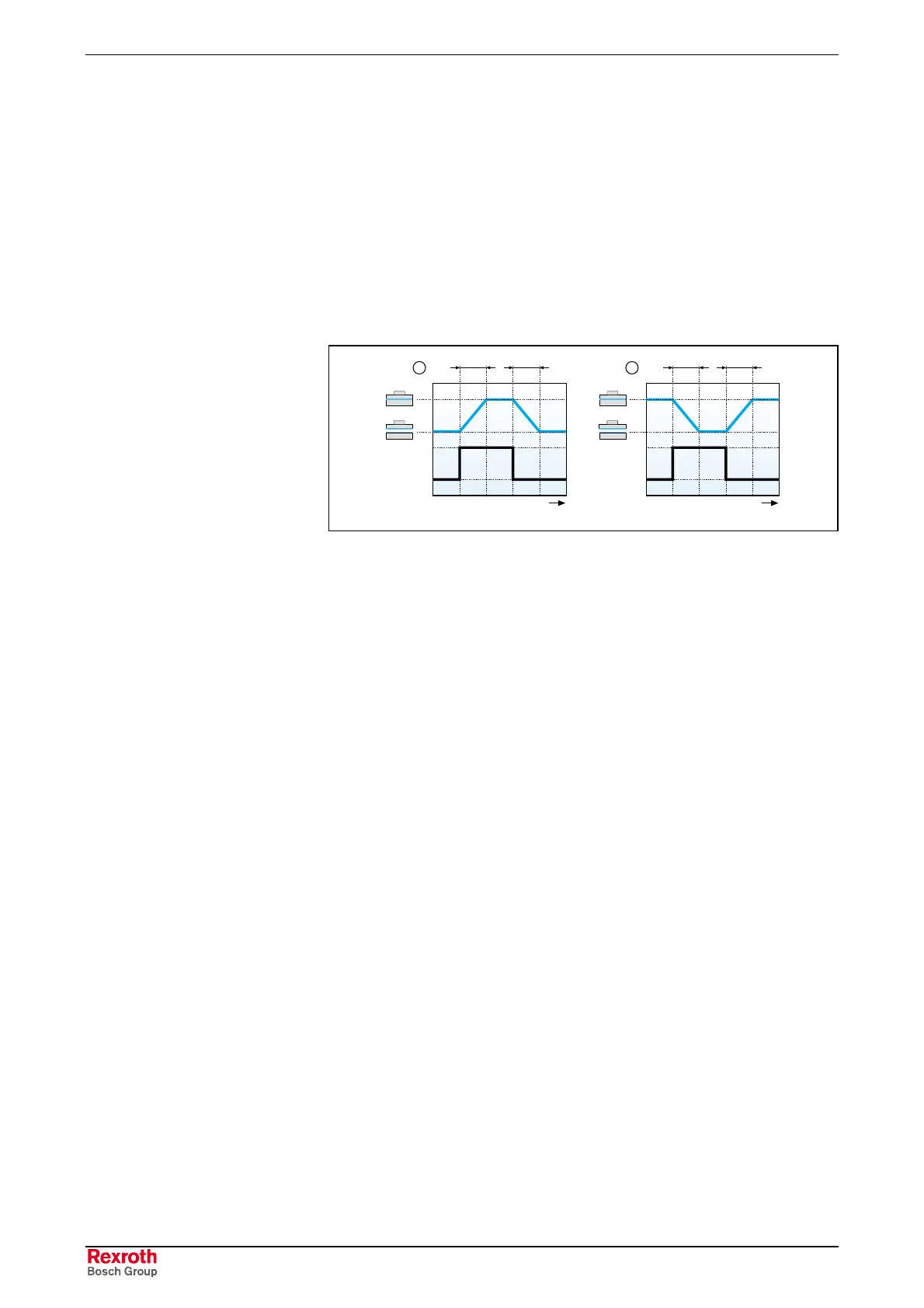

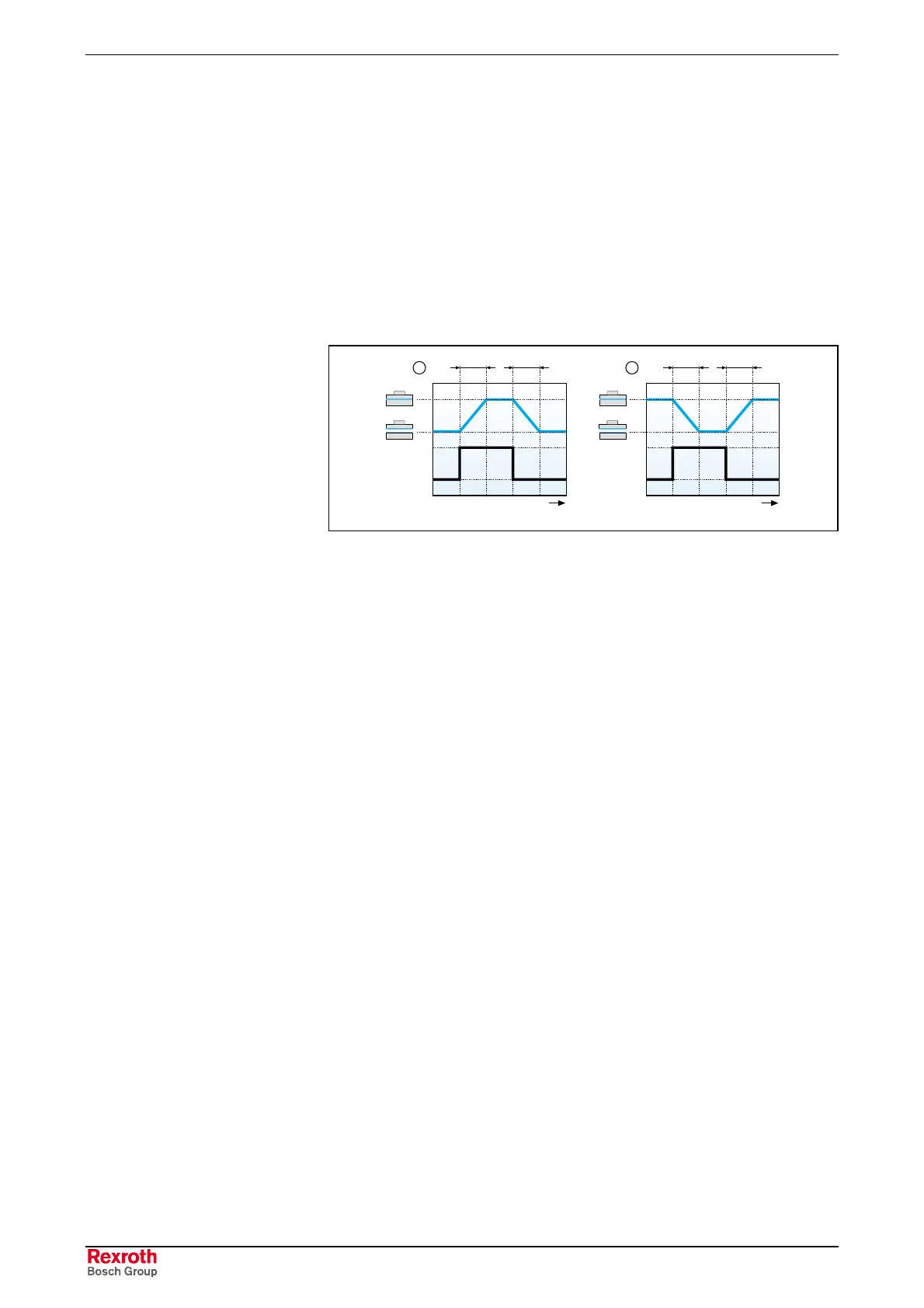

t

1

2

U

n

[V]

0

24

U

n

[V]

0

24

t

1

t

2

t

1

t

2

t

brake.EPS

(1): Electrically-clamped brake

(2): Electrically-released brake

t

1

:

Clamp delay

t

2

: Releasing time

Fig. 9-17: Holding brake diagram

Main Spindle Applications

An electrically-clamped holding brake can be used to lock a main

spindle during standstill and when the control ”controller enable” signal is

off, e.g. when a tool change is performed without a closed position loop.

⇒ Clamp the motor only at standstill, i.e. after the controller has signaled

the motor is at standstill.

An electrically-released holding brake should not be used on main

spindles. Unintentional clamping of the holding brake at high motor

speeds can lead to extreme deterioration or even demolition of the brake

(e.g. in the case of power loss or wire breakage).

Functional test

Electrically-clamped Holding

Brake

Loading...

Loading...