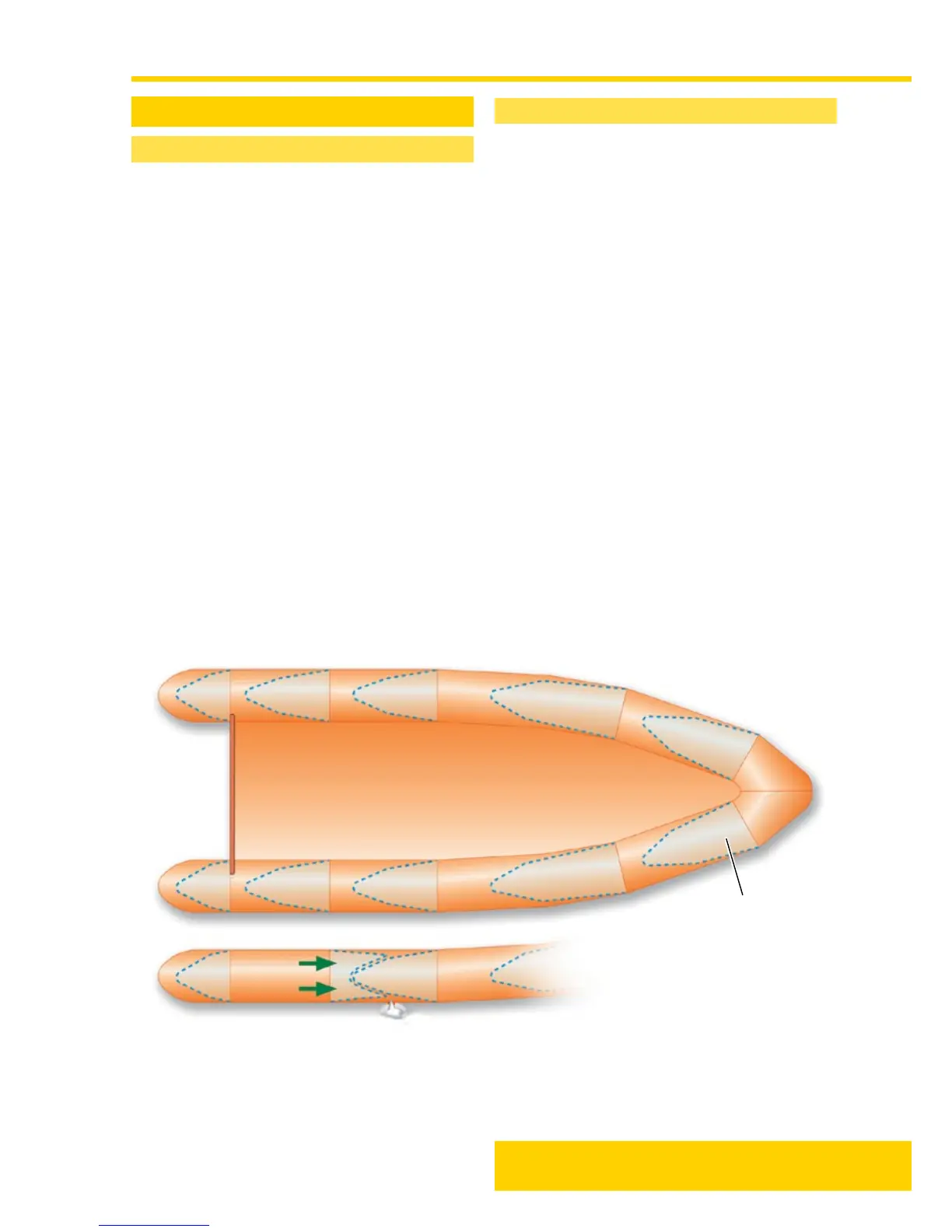

Buoyancy tubes

Design and function

The sponson is divided into ten separate airtight

compartments to provide continuous buoyancy in the

event of damage being incurred. Each compartment

contains a cone that when pressurised faces aft but

should a section become damaged the pressure in the

adjacent section will force the cone back on itself to fill

the punctured area.

For this safety system to work it is essential that the

compartments are inflated from the bow, working aft.

The normal working pressure of all compartments in the

sponson is 1.5 pounds per square inch (psi). Although

pressures between 0.75 and 2.0 psi are acceptable.

The entire buoyancy tube should be periodically examined

for undue wear or leaks and the pressure of each

compartment checked. Wear will reduce the thickness of

the Hypalon coating and pressure will be lost.

Leaks can be found by applying soapy water to the

suspected areas.

cone-shaped

bulkhead

In the event of a leak, pressure will cause the cone-

shaped bulkhead in the adjoining compartment to invert,

effectively filling most of the damaged compartment

Tube repairs

Most small punctures can be repaired with a patch. The

procedure for gluing should be carried out in accordance

to the training given.

Relevant COSHH and risk assessments must be read prior

to any work being carried out. These assessments will cover

dangers to your health and others as well as ventilation

and Personal Protective Equipment (PPE) considerations.

The repair must be carried out in a well ventilated area

and also be allowed to cure in a warm, dry environment

otherwise the materials will not bond fully.

Stores required:

• Bostik 2402 two part adhesive (part number: 7-74)

• Bostik M-501 solvent (part number: 7-129)

• seam roller (part number: 7-1979)

• sandpaper (grade 80)

• chinagraph pencil

• crepe rubber

• rags

• hot air gun

• scraper

• pincers and scissors.

Loading...

Loading...