14 Rockwell Automation Publication 440R-UM013G-EN-P - December 2022

Chapter 2 Installation

Spacing

You can mount safety relays directly next to other safety relays. When using the EtherNet/IP™

module, you must mount the safety relay within 10mm (0.4 in.) of the neighboring module to

maintain effective communication.

Maintain a space of 50.8 mm (2 in.) above, below, and in front of the safety relay for adequate

ventilation.

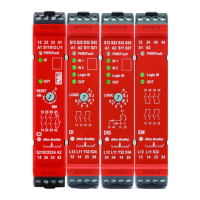

Removable Terminals Safety relays have removable terminals to ease wiring and replacement.

Figure 4 - Removable Terminals

1. Insert the tip of a small screwdriver into the slot near the terminal screws.

2. To unlock the terminal block, rotate the screwdriver.

You can now remove the terminal block from the housing.

Enclosure Considerations Most applications require installation in an industrial enclosure to reduce the effects of

electrical interference and environmental exposure. Pollution Degree2 is an environment

where normally only non-conductive pollution occurs with the expectation that condensation

causes occasional temporary conductivity. Overvoltage Category II is the load level section of

the electrical distribution system. At this level, transient voltages are controlled and do not

exceed the impulse voltage capability of the product insulation.

This equipment is intended for use in a Pollution Degree 2 industrial environment, in

overvoltage Category II applications (as defined in IEC 60664-1), at altitudes up to 2000 m

(6562 ft) without derating. This equipment is considered Group 1, Class A industrial equipment

according to IEC/CISPR 11. Without appropriate precautions, there can be difficulties with

electromagnetic compatibility in residential and other environments due to conducted and

radiated disturbances.

This equipment is supplied as open-type equipment. The safety relays must be mounted

within an enclosure that is suitably designed for those specific environmental conditions that

are present and appropriately designed to help prevent personal injury as a result of

accessibility to live parts. The enclosure must have suitable flame-retardant properties to help

prevent or minimize the spread of flame, in compliance with a flame spread rating of 5VA, V2,

V1, V0 (or equivalent) if non-metallic. The interior of the enclosure must be accessible only by

the use of a tool. Subsequent sections of this publication contain additional information

regarding specific enclosure-type ratings that are required to comply with certain product

safety certifications.

For more information, see publications:

• 1770-4.1

, for additional installation requirements.

• NEMA Standard 250 and IEC 60529, as applicable, for explanations of the degrees of

protection provided by different types of enclosure.

Loading...

Loading...