Rockwell Automation Publication 440R-UM013G-EN-P - December 2022 17

Chapter 3

Power, Ground, and Wire

Wiring Requirements and

Recommendation

• Allow adequate space between the I/O wire ducts and the top and bottom of the safety

relays and front face to maintain an ambient temperature below the rated operating

temperature of the safety relays.

• Route incoming power to the safety relay by a path separate from the device wiring.

Where paths must cross, their intersection must be perpendicular.

• Do not run signal or communications wiring and power wiring in the same conduit.

Route wires with different signal characteristics by separate paths.

• Separate wiring by signal type. Bundle wiring with similar electrical characteristics

together.

• Separate input wiring from output wiring.

• Label wiring to all devices in the system. Use tape, shrink-tubing, or other more

dependable means to label wire. Use colored insulation as well to identify wiring by

signal characteristics. For example, use blue for DC wiring and red for AC wiring.

Wire Size

Each terminal accommodates copper wire with size from 0.2…2.5 mm² (24…14 AWG). Use

copper that withstands 60…75 °C (140…167 °F).

Terminal Torque

Torque terminals to 0.4 N•m (4 lb•in).

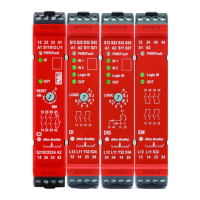

Terminal Assignments

Safety relays have four terminals: two on the top and two on the bottom. As shown in Figure 5

on page 18, the X2 and X4 terminal markings apply to the rear terminals. The X1 and X3

terminals apply to the front terminals.

ATTENTION: Before you install and wire any device, disconnect power to the

system.

ATTENTION: Calculate the maximum possible current in each power and

common wire. Observe all electrical codes that dictate the maximum

current allowable for each wire size. Current above the maximum rating

causes the wiring to overheat, which can cause damage.

Loading...

Loading...