106 Rockwell Automation Publication ICSTT-RM447M-EN-P - July 2019

Chapter 6 Specifying a New Controller

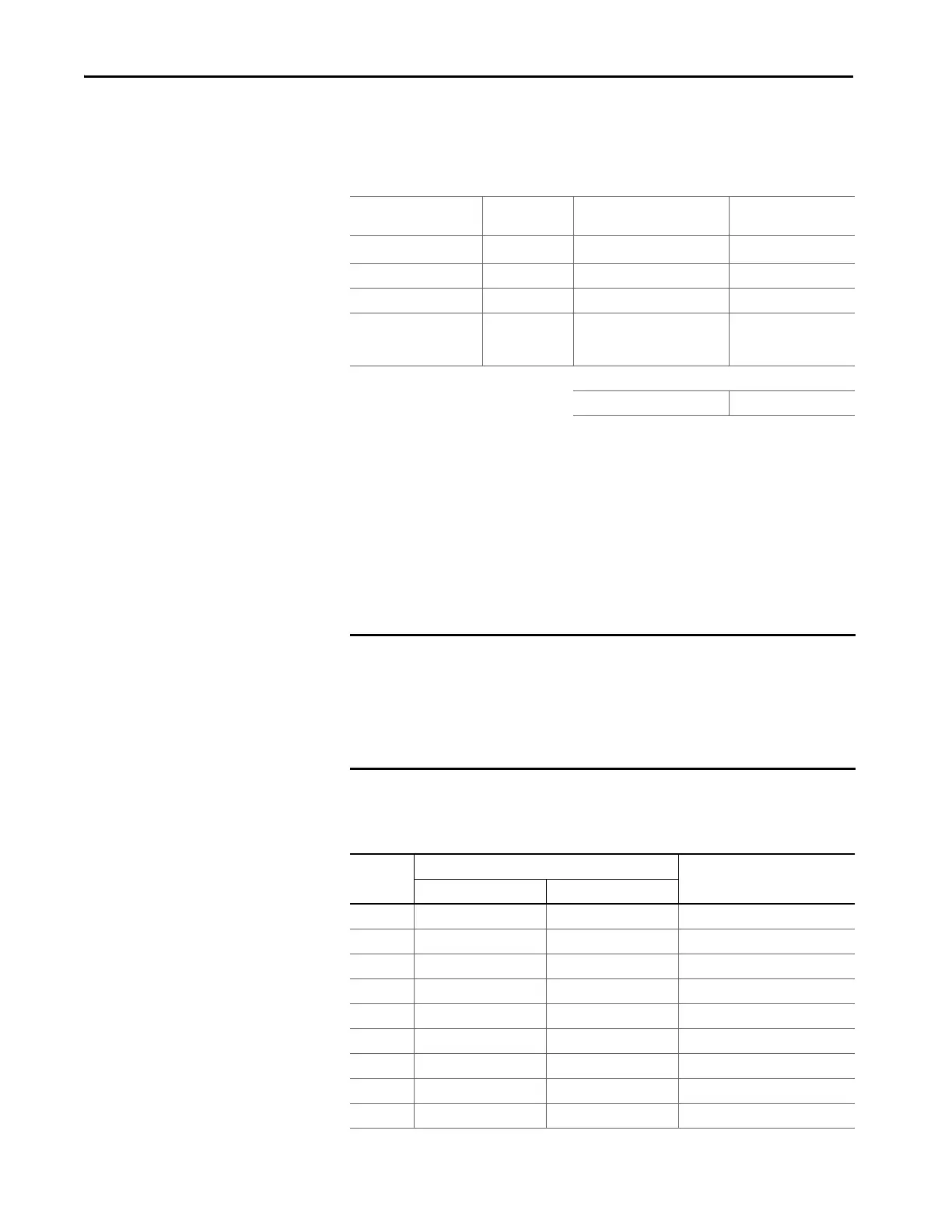

Table 20 - Field Loop Power Heat Dissipation

The field loop power heat dissipation is generated from the input voltages and

currents + the output currents:

1

The maximum field loop power heat dissipation for analogue outputs should

be calculated at an output current corresponding to the smaller of the

Maximum Channel Output Current OR Field Voltage/(2 x Load Resistance)

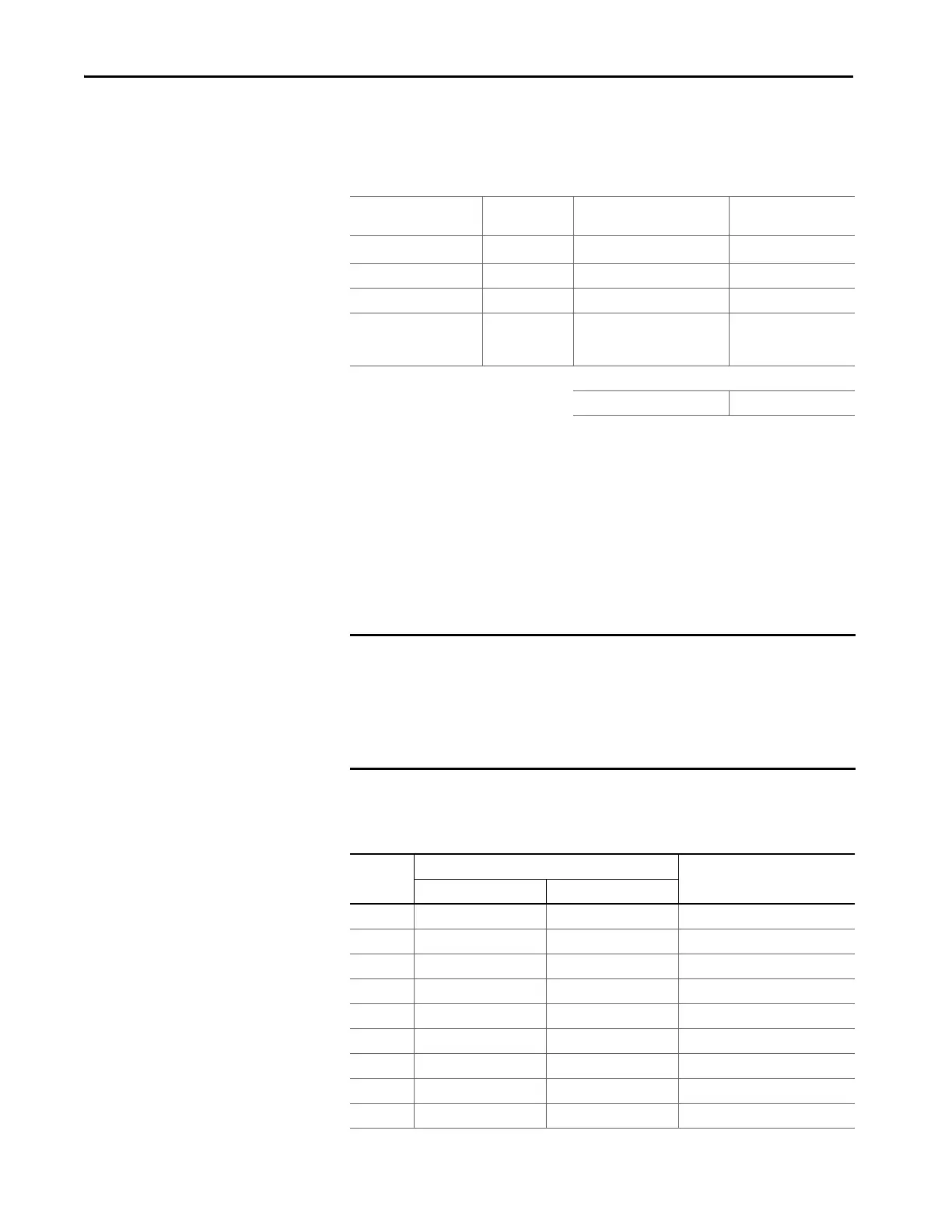

Backplane Electrical Ratings

To comply with UL/CSA standards use the following voltage and current

ratings for the Processor and I/O Backplanes when designing your power

distribution:

Table 21 - Maximum Electrical Rating Values

Item Number of Field

Loops

Field Loop Power Heat

Dissipation

Subtotal

(W x 3.412 BTU/hr)

Digital Inputs × Input Voltage (V)/5125 =

Analogue Inputs × Input current (A) x 135 =

Digital Outputs x Output current (A) x 0.57 =

Analogue outputs x (Field voltage(V) x Output

Current (A) - load Resistance (Ω)

x Output current (A)

1

=

Tot al :

IMPORTANT These are the maximum allowed electrical ratings given by UL

for the backplane load installed with the relevant TAs and

modules. They are not operating values so don't use them to

calculate the controller power consumption or heat

dissipation values. Refer to the separate topics on estimating

Heat Dissipation and Power Consumption.

Module Back-plane Electrical Ratings Input/Output Electrical Ratings

Voltage Range (Vdc) Maximum Current (mA)

9100 18-32 10.4A (400 mA per slot) -

9300 18-32 9.6A (400 mA per slot) -

9110 18-32 380 -

9401 18-32 260 Input: 18-32 Vdc @ 24 mA

9402 18-32 260 Input: 0-32 Vdc @ 6.5 mA

9431 18-32 260 Input: 0-32 Vdc @ 6.5 mA

9432 18-32 260 Input: 18-32 Vdc @ 24 mA

9481 18-32 260 Output: 18-32 Vdc/0-20 mA

9482 18-32 260 Output: 18-32 Vdc/0-20 mA

Loading...

Loading...