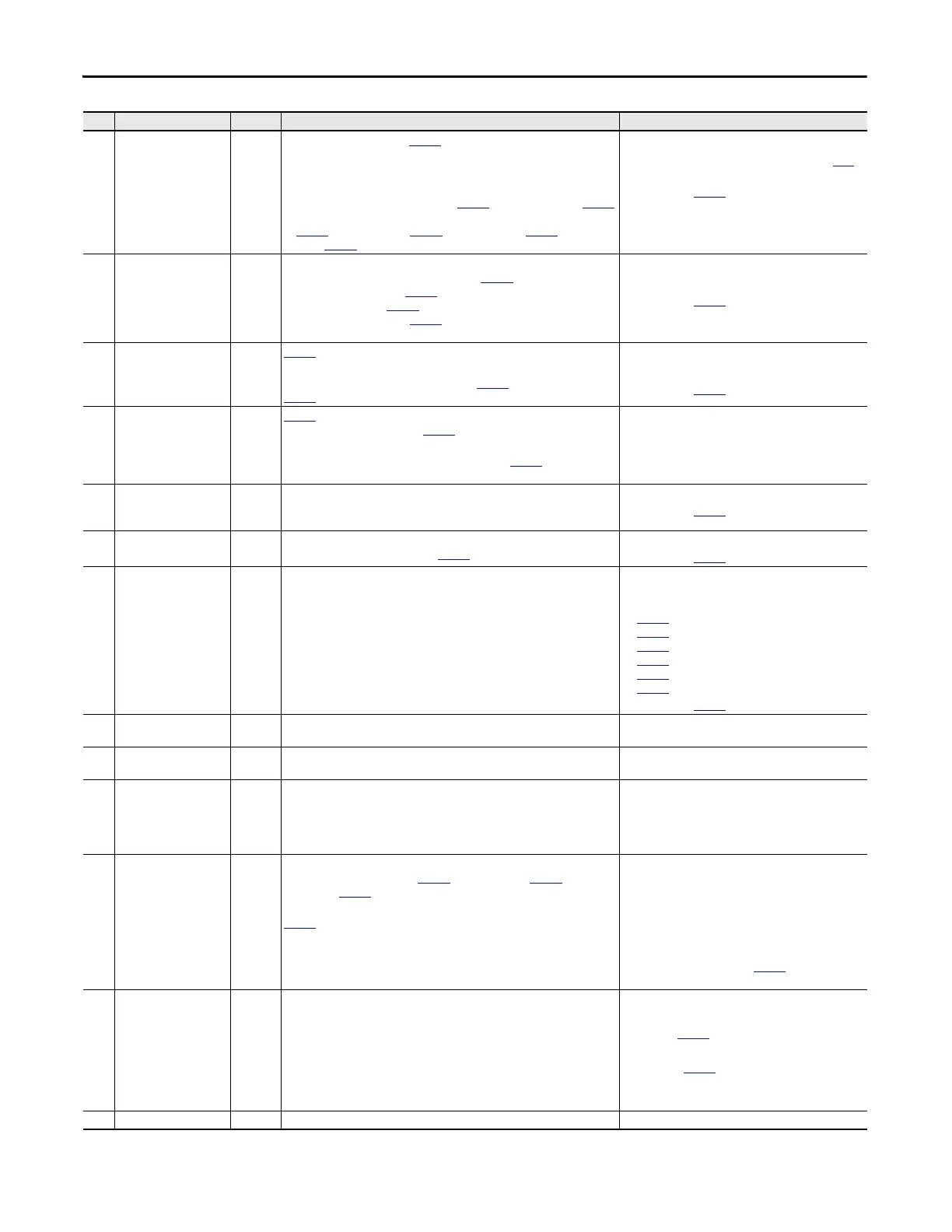

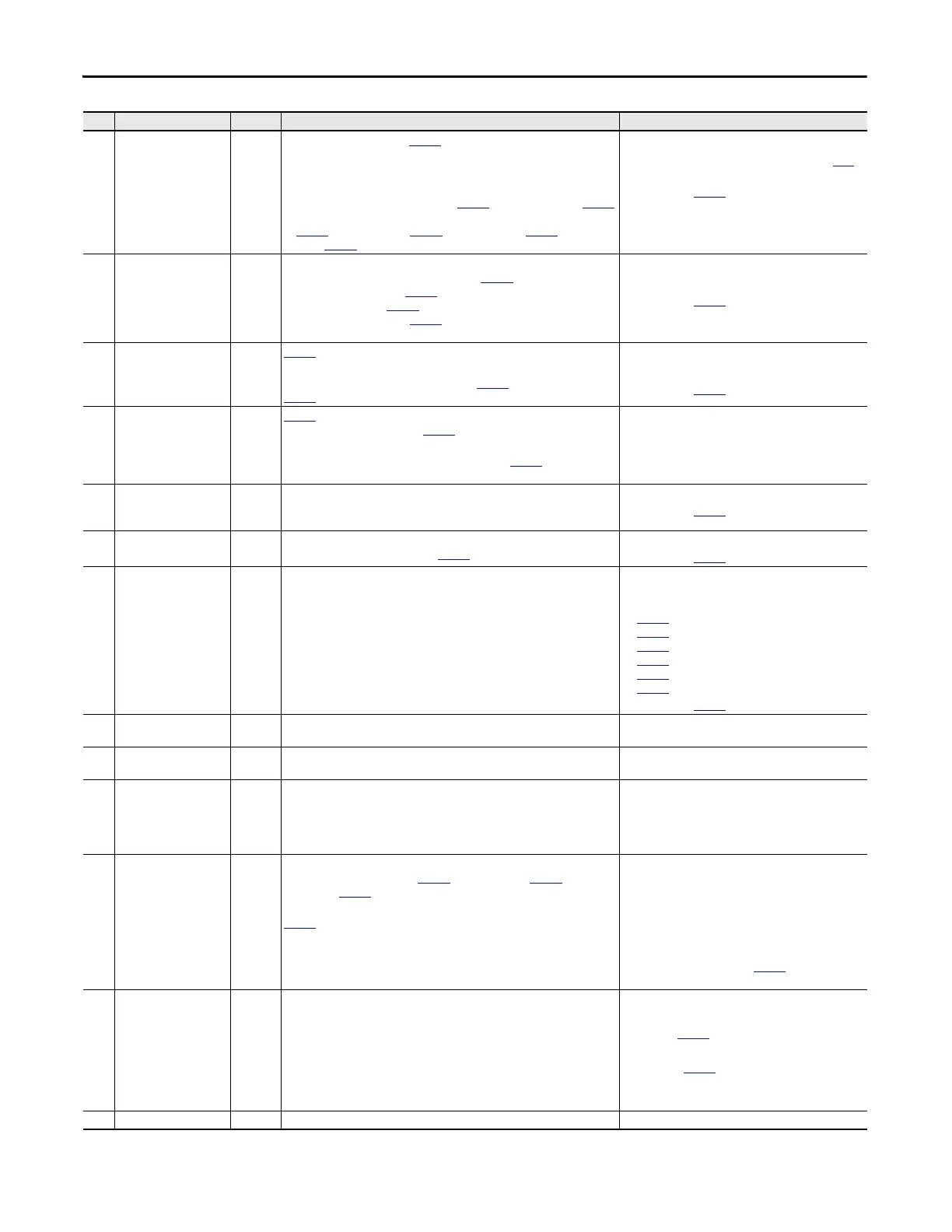

144 Rockwell Automation Publication 20D-PM001D-EN-P - March 2019

Chapter 3 Troubleshooting

12 Motor OLoad Pend 2 A motor overload is pending. Par

308 [Output Current] is squared, scaled and

integrated over time. When this integrated value exceeds 0.5, this exception

event occurs.

The integrator's output can be viewed in Par 330 [Fault TP Data] when Par 329

[Fault TP l] is set to 13 “Mtr OL Outpt”. The overload integration rate is affected

by Par

336 [Motor OL Factor], Par 337 [Mtr I2T Curr Min], Par 338 [Mtr I2T Spd

Min] and Par 339 [Mtr I2T Calibrat].

• Reduce the mechanical load.

• Enter correct motor nameplate full load amps Par

2

[Motor NP FLA].

Configured with Par

371 [Mtr OL Trip Cnfg].

13 Motor Stalled 2 The motor has stalled. The three conditions listed below have occurred at the

same time for the amount of time specified in Par

373 [Motor Stall Time]:

1. The drive is not stopped (Par 150 [Logic State Mach] is not equal to zero).

2. The drive is on limit (Par 304 [Limit Status] is not equal to zero).

3. The drive is at zero speed (Par 155 [Logic Status], bit 13 “At Zero Spd” is

set).

• Increase the torque limit.

• Reduce the mechanical load.

Configured with Par

374 [Motor Stall Cnfg].

14 Inv OTemp Pend 2 Par

313 [Heatsink Temp] is within 10°C of maximum.

View the maximum heat sink temperature in Par 348 [Drive OL TP Data] when

Par 347 [Drive OL TP l] is set to 30 “fMaxHsDegc”.

• Reduce the mechanical load.

• Lower the ambient temperature.

Configured with Par

375 [Inv OT Pend Cnfg].

15 Inv OTemp Trip 1 Par

313 [Heatsink Temp] is above the maximum limit or a temperature sensor

has failed (shorted or open). See Par 346 [Drive OL Status], bit 0 “NTC Shorted”

and bit 1 “NTC Open”.

Or, the calculated junction temperature (displayed in Par 345 [Drive OL

JnctTmp]) of the power semiconductors in the inverter has been exceeded.

• Reduce the mechanical load.

• Lower the ambient temperature.

16 Inv OLoad Pend 2 The drive's operating point is approaching the intermittent current rating

limitation. If output current remains at or above present levels, an inverter

overload condition will occur.

Reduce the load on the drive.

Configured with Par

376 [Inv OL Pend Cnfg].

17 Inv OLoad Trip 2 The drive's operating point has exceeded the intermittent current rating and a

foldback to the continuous rating in Par

400 [Rated Amps] has occurred.

Reduce the mechanical load.

Configured with Par

377 [Inv OL Trip Cnfg].

18 Ext Fault Input 2 A digital input has detected an external fault. Enter a value of 3 “Ext Fault” or 38 “ExtFault Inv” in one

of the following parameters to configure an input to

detect an external fault:

• Par

825 [Digin 1 Sel]

• Par 826 [Digin 2 Sel]

• Par 827 [Digin 3 Sel]

• Par 828 [Dig In4 Sel]

• Par 829 [Dig In5 Sel]

• Par 830 [Dig In6 Sel]

Configured with Par 379 [Ext Flt/Alm Cnfg].

19 DSP Memory Error 1 Flash memory does not match the SRAM memory. Cycle the drive power. If the fault remains, replace the

Main Control board.

20 DSP Device Error 1 A DSP (Velocity Position Loop) interrupt task has not been completed in the

allotted time.

Cycle the drive power. If the fault remains, replace the

Main Control board.

22 Over Frequency 1 The Encoderless algorithm failed to converge on the correct speed. Two

possible causes include:

1. The Velocity regulator is attempting to run below the motor’s slip speed.

2. The Frequency regulator “pulls out” and the commanded motor frequency

slows to the maximum frequency limit.

23 MC Commissn Fail 1 The drive has failed to complete either the Motor Autotuning procedure or the

Power Circuits Diagnostics test. Par

463 [MC Diag Error 1], Par 464 [MC Diag

Error 2], and Par 465 [MC Diag Error 3] display Motor Autotuning and Power

Circuit Diagnostic faults.

Par

465 [MC Diag Error 3] - Drive current, inductance, voltage and speed are

not within motor nameplate specifications. This fault occurs most frequently

on low horsepower motors.

• Verify that the motor nameplate data is entered

correctly into the drive.

• Verify that the motor is wired for the correction

voltage entering into the drive.

• Verify that the encoder (if used) and velocity

feedback is correct.

• Change the tuning mode in Par

515 [FVC Tune Config]

to 9 “NoRotate Tune”.

24 DC Bus Overvolt 1 A DC Bus overvoltage has occurred. • Verify the AC Line.

• Verify that either the brake or bus regulator is

enabled (Par 414 [Brake/Bus Cnfg], bit 0 “Brake

Enable” or bit 3 “Bus Reg Enable”, respectively).

• Verify that Par

128 [Regen Power Lim] is set properly.

• If Par 414 [Brake/Bus Cnfg] bit 0 “Brake Enable” is set,

verify that the braking resistor is properly sized.

25 Inv Trans Desat 1 The IGBT detects a transistor failure (Desaturation).

No. Name Type

(1)

Description Action

Loading...

Loading...