Rockwell Automation Publication 2198-RM003B-EN-P - November 2020 75

Chapter 5 System Architecture

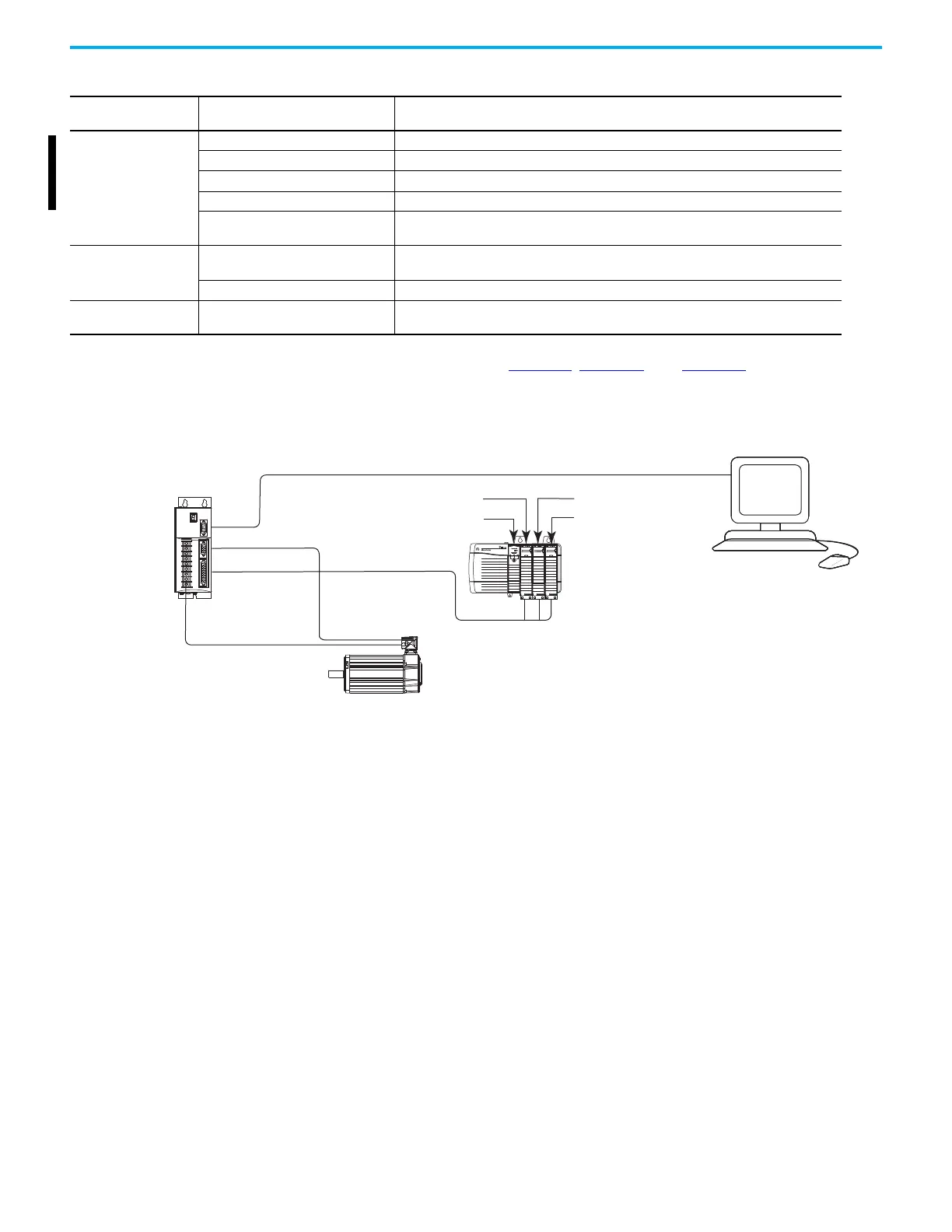

This system examples in Figure 41, Figure 42, and Figure 43 illustrate how the

required drive modules and accessories are used in a typical Ultra3000 servo

drive system.

Figure 41 - Ultra3000 Servo Drive System Architecture (Serial Interface)

Cables

2090-CFBM6Dx-CxAAxx Motor feedback cables for Kinetix TLY servo motors.

2090-CPxM6DF-16AAxx Motor power/brake cables for Kinetix TLY servo motors.

2090-CFBM7DF-CEAxxx Motor feedback cables for Kinetix MP servo motors with Hiperface encoders.

2090-CPxM7DF-xxAxxx Motor power/brake cables for Kinetix MP servo motors.

2090-XXNFMF-Sxx

2090-CFBM7DF-CDAFxx

Standard and continuous-flex feedback cables that include additional conductors for use

with incremental encoders.

AC Line Filters

2090-UXLF-xxx

AC line filters with 6 A, 10 A, 23 A, 32 A, 36 A, and 50 A are available for Ultra3000 (230V) drive

systems.

2090-UXLF-HVxxx AC line filters with 23 A, 30 A, and 50 A are available for Ultra3000 (460V) drive systems.

External Shunt Modules

2090-UCSR-xxxx, 9101-1183, and 2090-

SRxxx-xx

External shunt modules are available when the Ultra3000 drive internal shunt capability is

exceeded.

Table 63 - Typical Ultra3000 Servo Drive System (Continued)

Ultra3000 Drive System

Component

Cat. Nos. Description

Output

Logix Interface Module

Commissioning and Communication

Ultraware

Software

Motor Feedback

I/O and Commands

Motor Power

Logix Controller

Input

Logix Platform

(ControlLogix is shown)

MP-Series and TL-Series

Rotary Motors

(MPL-A xxxx motors shown)

Ultra3000 Drive

Other compatible motors/actuators include:

• MP-Series Integrated Linear Stages

• MP-Series Electric Cylinders

• LDC-Series and LDL-Series Linear Motors

2098-DSD-xxxxxx-xx)

Loading...

Loading...