Startup and operation

Page 26 RES-445

9.5 Startup procedure

Please also refer to Kap. 1 „Safety and warning notes“

auf Seite 4 and Kap. 2 „Application“ auf Seite 5.

Installation and startup may only be per-

formed by technically trained, skilled per-

sons who are familiar with the associated risks and

warranty provisions.

9.5.1 Initial startup

Prerequisites: The controller must be correctly installed

and connected ( Kap. 8 „Installation“ auf Seite 13).

The possible settings are described in detail in

chap. 9.3 „Controller configuration“, page 20 and

chap. 10 „Controller functions“, page 27.

The essential controller configurations are described

below:

1. Switch off the line voltage and verify that all circuits

are deenergized.

2. The supply voltage specified on the nameplate of

the controller must be identical to the line voltage

that is present in the plant or machine. The line fre-

quency is automatically detected by the tempera-

ture controller in the range from 47 to 63Hz.

3. In case of controllers up to software revision 027,

the setting of the DIP switches on the controller are

indicated in the ROPEX Application report and

depend on the heatsealing band (section 9.3 "Con-

troller configuration" on page 20).

4. Make sure that a START signal is not present.

5. Switch on the line voltage.

6. A power-up message appears on the display for

approximately 2 seconds when the controller is

switched on to indicate that it has been started up

correctly.

7. One of the following states then appears:

8. Set the controller configuration as described in

Kap. 9.3 „Controller configuration“ auf Seite 20. The

following settings are always required:

9. Activate the AUTOCAL function while the heatse-

aling band is still cold (with step 7 in the Settings

menu or by means of the "AUTOCAL" signal, termi-

nals 20+25). The progress of the calibration process

is indicated by a counter on the display (approx.

10…15s). A voltage of app. 0VDC appears at the

same time at the actual value output (terminals

20+24). If an ATR-x is connected, it indicates

0…3°C.

When the zero point has been calibrated, the dis-

play is reset to the home position and 20°C is indi-

cated as the actual value. A voltage of 0.66VDC (for

the 300°C range) or 0.4VDC (for the 500°C range,

equivalent to 20°C, appears at the actual value

output. If an ATR-x is connected, it must be set to "Z"

(20°C).

If the zero has not been calibrated successfully, an

erro message indicates error codes 104…106, 211.

In this case the controller configuration is incorrect

( Kap. 9.3 „Controller configuration“ auf Seite 20

and ROPEX Application Report). Repeat the zero

point calibration after the controller has been confi-

gured correctly.

10.When the zero point has been calibrated suc-

cessfully, the main menu appears on the display

again. Then specify a defined temperature (heatse-

aling temperature) with step 1 in the Settings menu

(or apply a 0…10VDC voltage to the analog input,

terminals 20+23) and activate the "START" signal

(HEAT). Alternatively, a heatsealing process can be

started by pressing the "HAND" key (display in

home position). The indication of the ACTUAL tem-

perature on the display (digital value and dynamic

bar) permits the heating and control process to be

monitored.

The controller is functioning correctly if the tempera-

ture indicated on the display has a continuous

curve, in other words it must not jump abruptly, fluc-

tuate or deviate temporarily in the wrong direction.

This kind of behavior would indicate that the U

R

measuring wire has been laid incorrectly.

If an error code is displayed, please proceed as

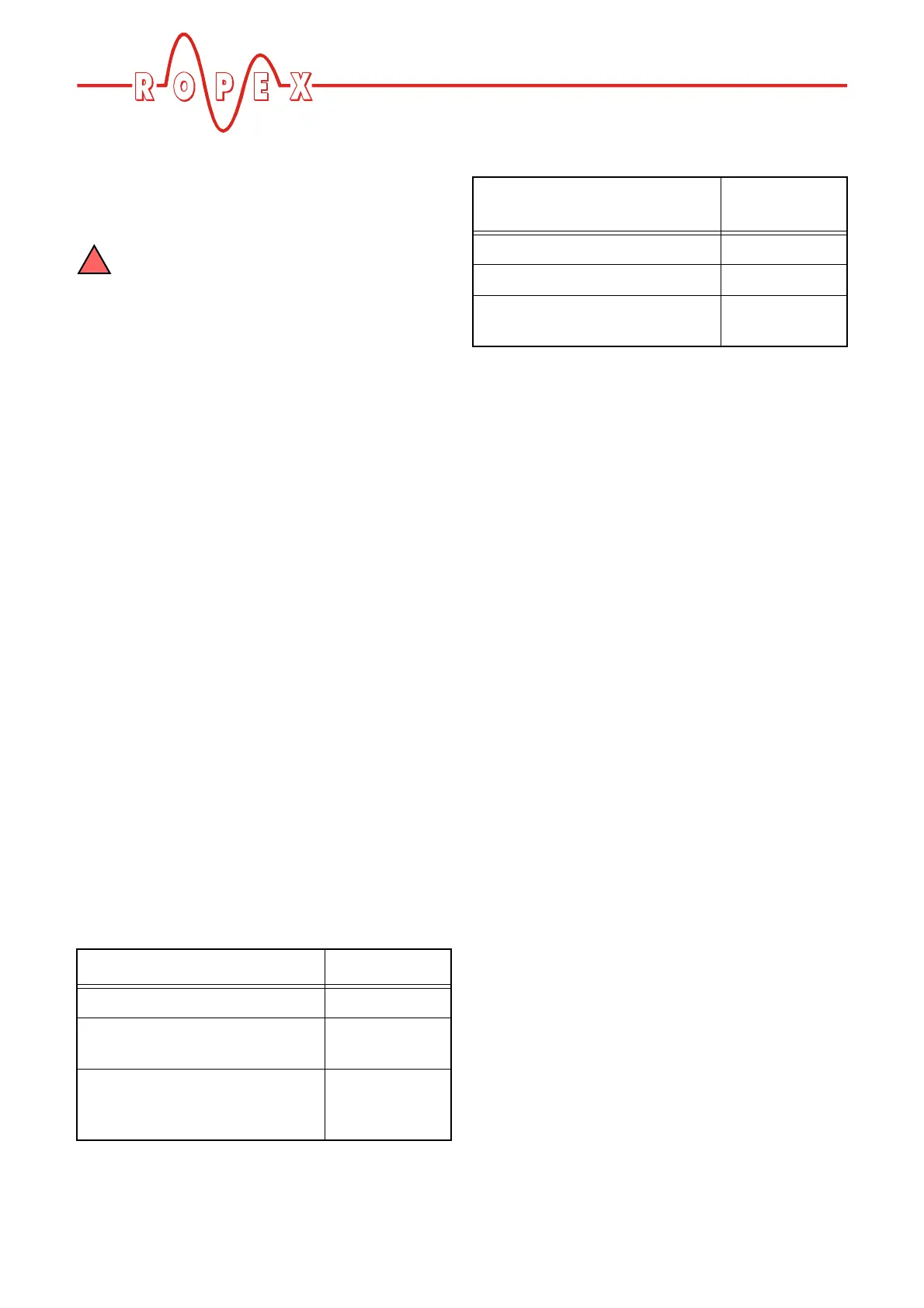

DISPLAY ACTION

Main menu Go to 8

Error message with error codes

104…106, 111…113, 211

Go to 8

Error message with error codes

101…103, 107, 108,

201…203, 801, 9xx

Fault diagnosis

( 10.27)

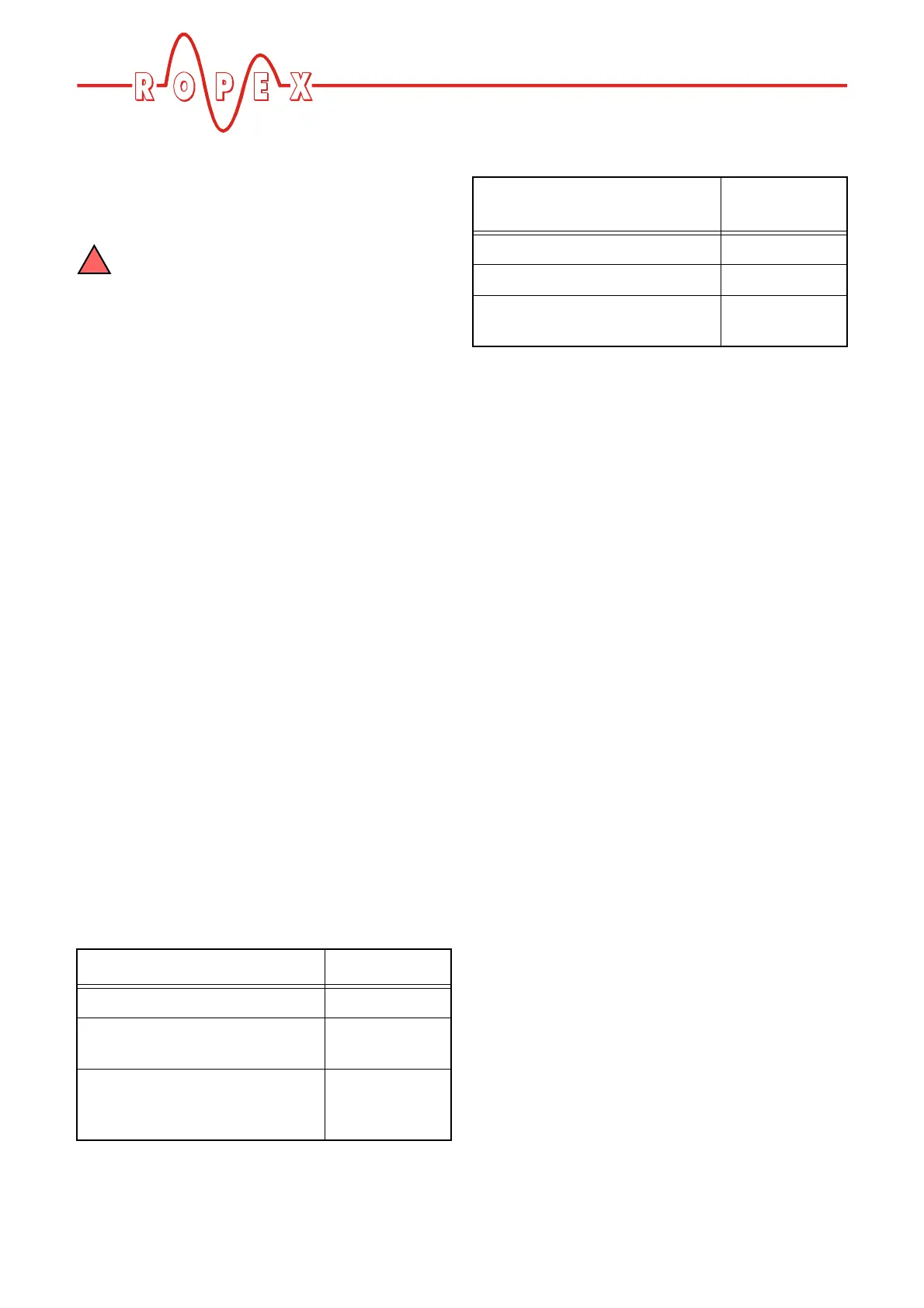

Setting

Step in Confi-

guration menu

Language 201 [20]

Restore factory settings 202 [21]

Temperature range and heatse-

aling band alloy

203, 204, 205

[22]

Loading...

Loading...