Reference Manual

00809-0100-4130, Rev AA

May 2009

Rosemount 2130

1-6

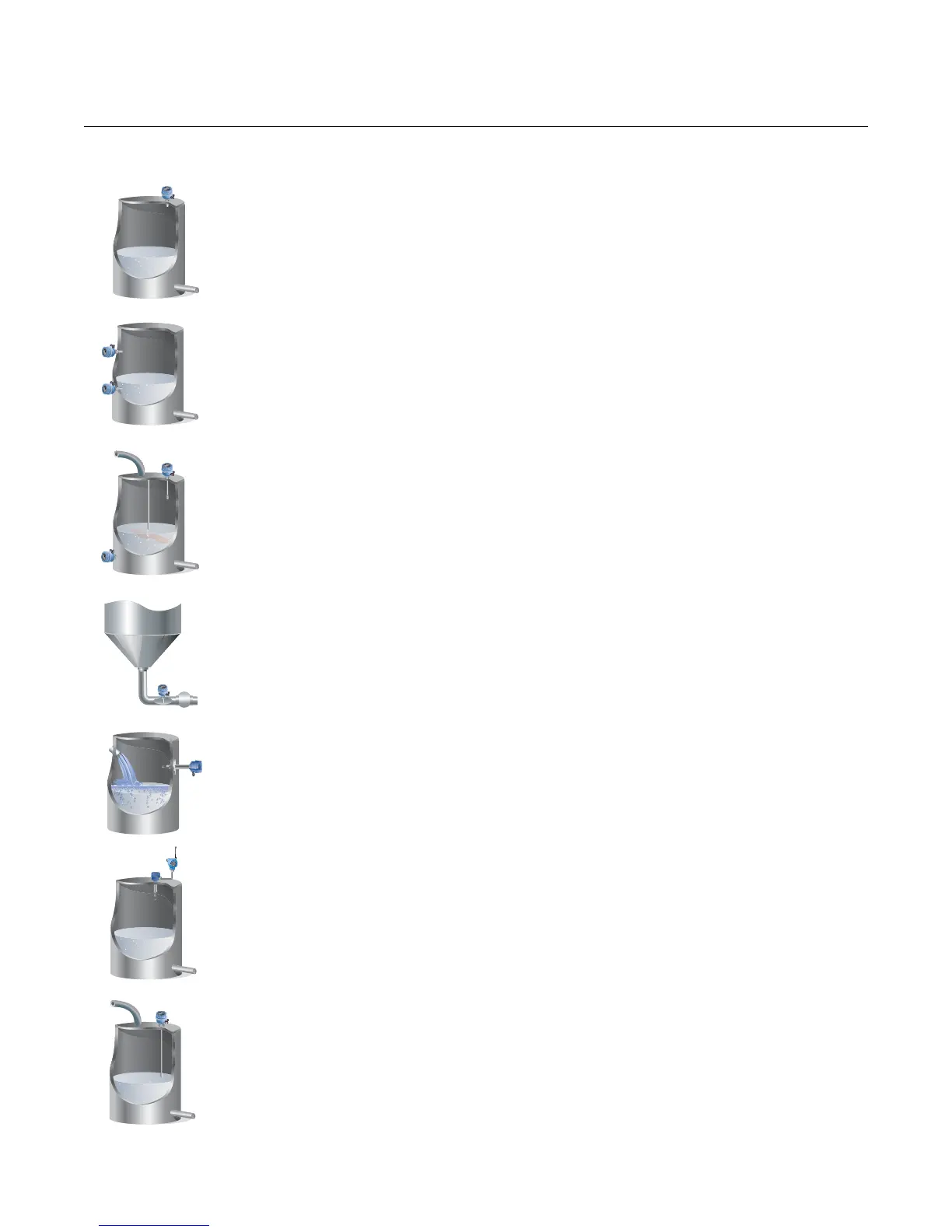

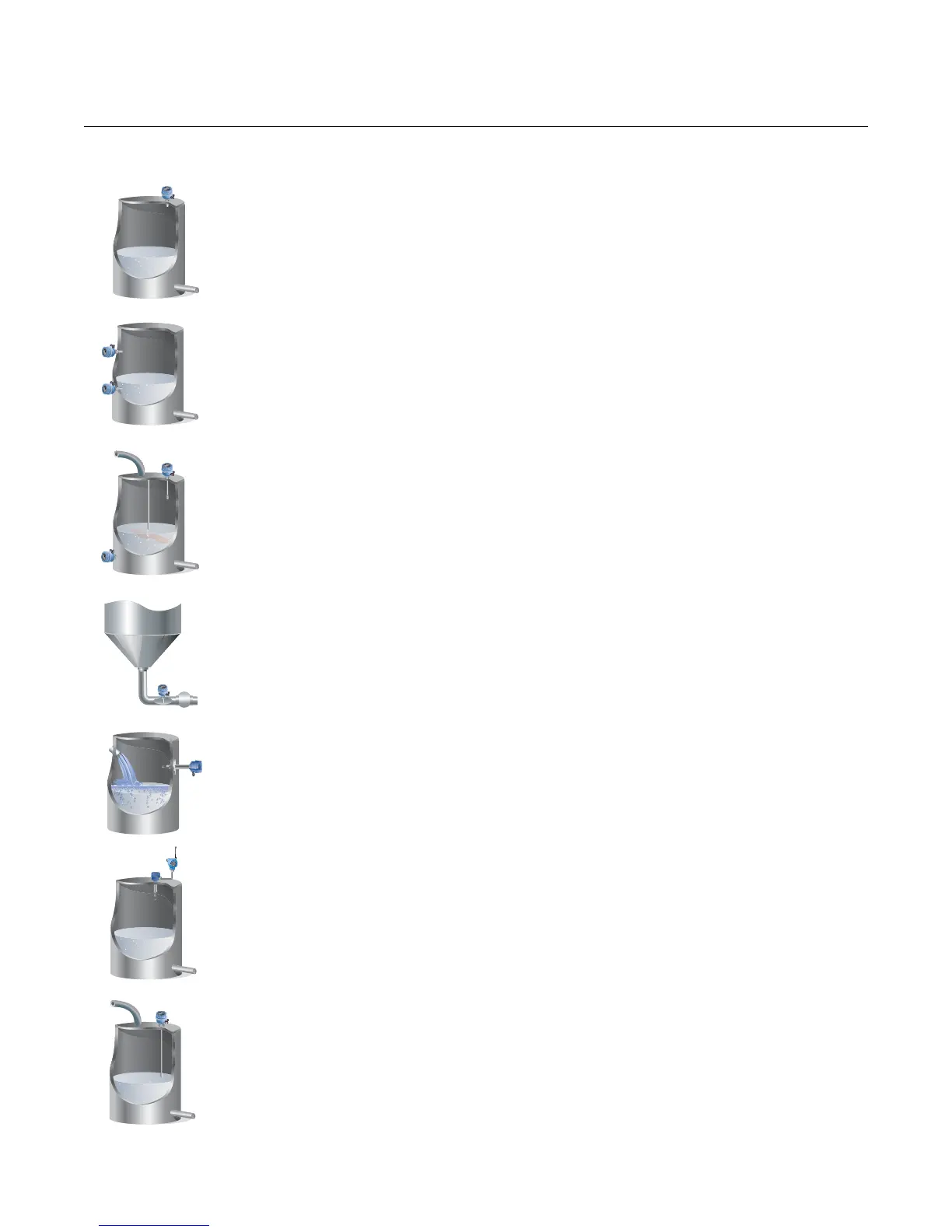

Figure 1-2. Rosemount 2130 Application Examples

Overfill Protection

Spillage caused by overfilling can be hazardous to people and the environment, resulting in

lost product and potentially high clean up costs.

High and Low Level Alarm

Maximum and minimum level detection in tanks containing different types of liquids are ideal

applications. The Rosemount 2130 is robust and operates continuously across the

temperature range of –94 to 500 °F (–70 to 260 °C) and operating pressures of up to 1450 psig

(100 barg), making it perfect for use as a high or low level alarm. It is common practice to have

an independent high level alarm switch as a backup to an installed level device in case of

primary failure.

Pump Control (Limit Detection)

Batch processing tanks often contain stirrers and agitators to ensure mixing and product

‘fluidity’. The standard user selectable time delay, from 0.3 to 30 seconds, virtually eliminates

the risk of false switching from splashing.

Pump Protection or Empty Pipe Detection

With the fork projecting only 2 in. (50 mm) (dependant on connection type), the 2130 can be

installed in small diameter pipes. Short forks mean minimum intrusion on the wetside and

allow for simple, low cost installation at any angle into your pipes or vessels. By selecting the

option of direct load switching electronics, the 2130 is ideal for reliable pump control and can

be used to protect against pumps running dry.

Extreme Temperature Applications

The 2130 is designed for extreme temperatures and is suitable for continuous operation within

the temperature range of –94 to 500 °F (–70 to 260 °C).

Wireless Applications

The advent of wireless communications allows process plant managers to save up to 90% on

installation cost compared with wired technologies. More data can be collected at central

locations than has ever been possible before. The 2130 can be used with a Rosemount 702

Wireless Transmitter to enable these benefits for your applications.

Hygienic Applications

With the highly polished forks option providing a surface finish (Ra) better than 0.8 µm, the

2130 meets the most stringent hygienic requirements used in food and beverage, and

pharmaceutical applications. Manufactured in stainless steel, the 2130 is robust enough to

easily withstand steam cleaning (CIP) routines for temperatures up to 500 °F (260 °C).

2

1

2

0

V

i

b

r

a

t

i

n

g

F

o

r

k

L

e

v

e

l

S

w

it

c

h

w

w

w

.

r

o

s

e

m

o

u

n

t

.

c

o

m

2

1

2

0

V

i

b

r

a

t

i

n

g

F

o

r

k

L

e

v

e

l

S

w

i

t

c

h

w

w

w

.

r

o

s

e

m

o

u

n

t

.

c

o

m

2

1

2

0

V

i

b

r

a

t

i

n

g

F

o

r

k

L

e

v

e

l

S

w

i

t

c

h

w

ww

.

r

o

s

e

m

o

u

n

t

.

c

o

m

2

1

2

0

V

i

b

r

a

t

i

n

g

F

o

r

k

L

e

v

e

l

S

w

i

t

c

h

w

w

w

.

r

o

s

e

m

o

u

n

t

.

c

o

m

2

1

2

0

V

i

b

r

a

t

i

n

g

Fo

r

k

L

e

v

e

l

S

w

i

t

c

h

w

ww.

r

o

s

e

m

o

u

n

t

.

c

o

m

2

1

2

0

V

i

b

r

a

t

i

n

g

F

o

r

k

L

e

v

e

l

S

w

i

t

c

h

w

w

w

.

r

o

s

e

m

o

u

n

t

.

c

o

m

2

1

2

0

V

i

b

r

a

t

i

n

g

Fo

r

k

L

e

ve

l

S

w

i

t

c

h

w

w

w

.

ro

s

e

m

o

u

n

t

.

c

o

m

Loading...

Loading...