Reference Manual

00809-0100-4130, Rev AA

May 2009

Rosemount 2130

A-2

Process Material

• 316L Stainless Steel (1.4404), or

Alloy C (UNS N10002) and Alloy C-276 (UNS N10276)

• Hand-polished to better than 0.8 m

– option available for hygienic connections

• Gasket material for

3

/4-in. and 1-in. BSPP (G) is non-asbestos BS7531

Grade X carbon fiber with rubber binder.

Dimensional Drawings

• See “Dimensional Drawings” on page A-5.

Performance Hysteresis (Water)

• ±0.039 in. (± 1 mm) nominal

Switching Point (Water)

• 0.5 in. (13 mm) from tip of fork (if vertical installation) or from edge of fork

(if horizontal installation) – this will vary with different liquid densities

Functional Maximum Operating Pressure

• The final rating depends on the type of tank connection:

Threaded Connection

See Figure A-1. Note: Clamp glands (02120-2000-0001 and 02120-2000-0002 on page A-14) limit the

maximum operating pressure to 18.85 psig (1.3 bar g)

Hygienic Connection

435 psig (30 bar g)

Flanged Connection

See Figure A-1 (Process Pressure) or Table A-2 (Maximum Flange Pressure), whichever is the lowest

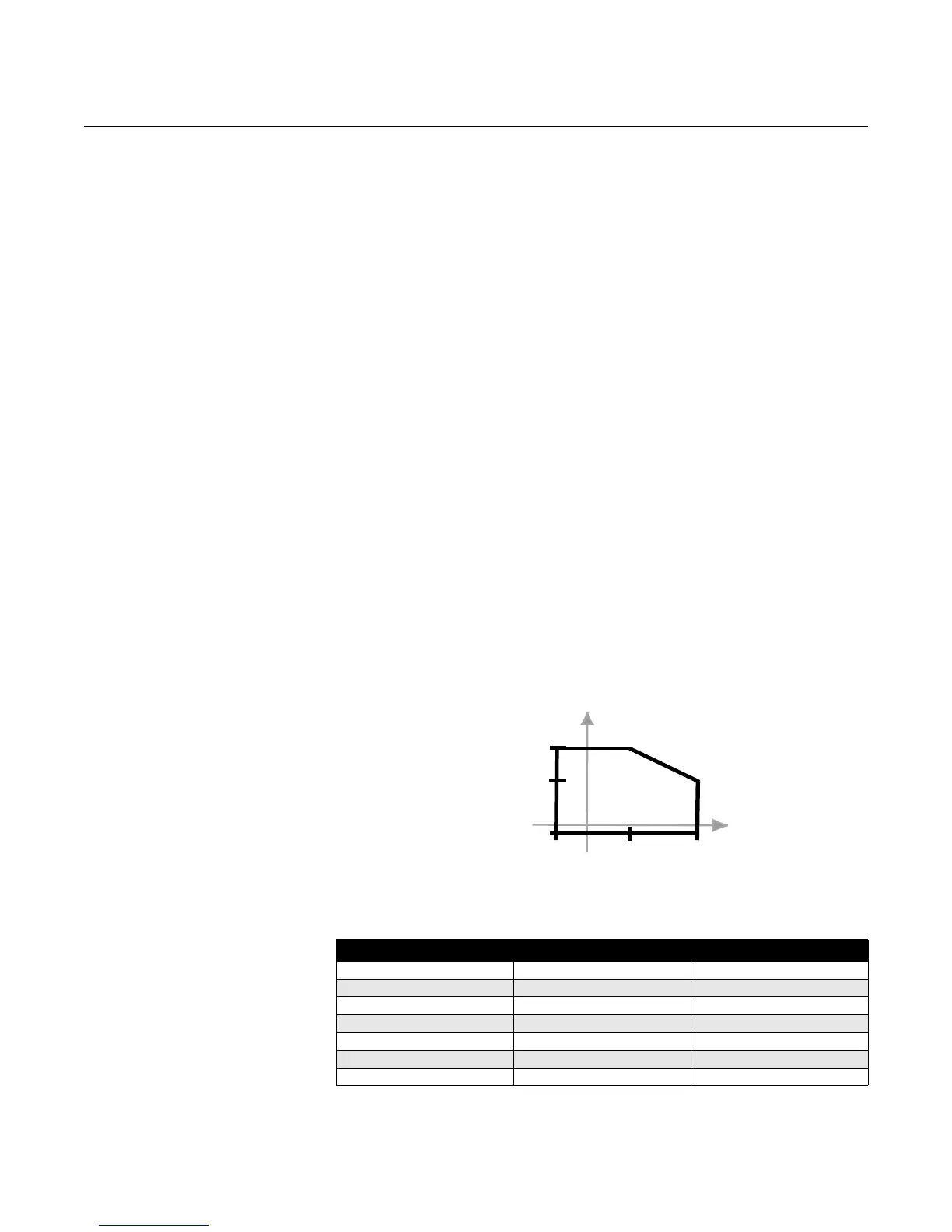

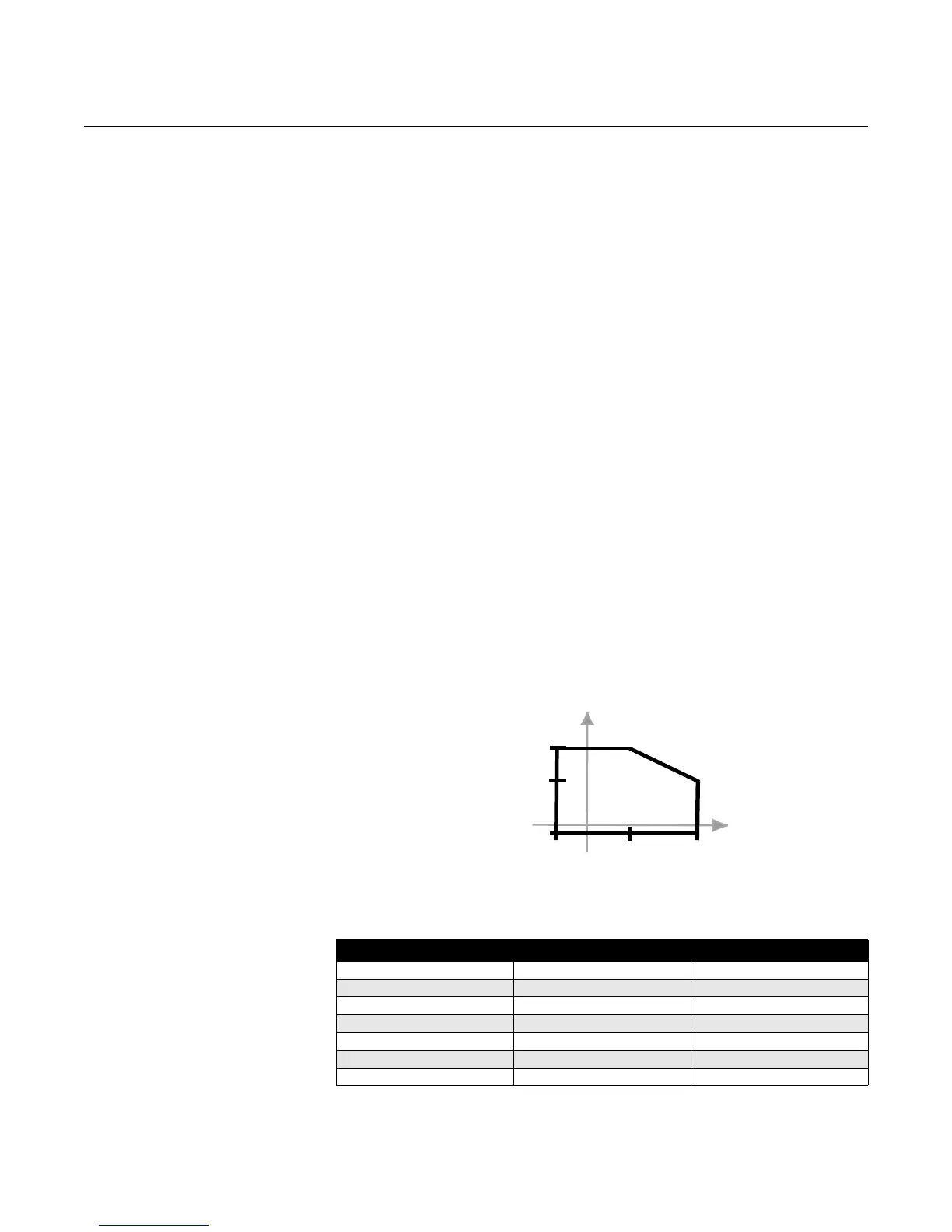

Figure A-1. Process Pressure

Table A-2. Maximum Flange Pressure Rating

Standard Class/Rating SST Flanges

ASME B16.5 Class 150 275 psig

(1)

(1) At 100 °F (38 °C), the pressure rating decreases with an increasing process temperature.

ASME B16.5 Class 300 720 psig

(1)

ASME B16.5 Class 600 1,440 psig

(1)

EN 1092-1 PN 10/16 15.7 barg

(2)

(2) At 248 °F (120 °C), the pressure rating decreases with an increasing process temperature.

EN 1092-1 PN 25/40 39.3 barg

(2)

EN 1092-1 PN 63 62.0 barg

(2)

EN 1092-1 PN 100 98.4 barg

(2)

1450 (100)

885 (61)

-14.5 (-1.0)

-94

(-70)

68

(20)

500

(260)

Process Temperature °F (°C)

Process Pressure psig (barg)

32 (0)

32

(0)

The 2130

Loading...

Loading...