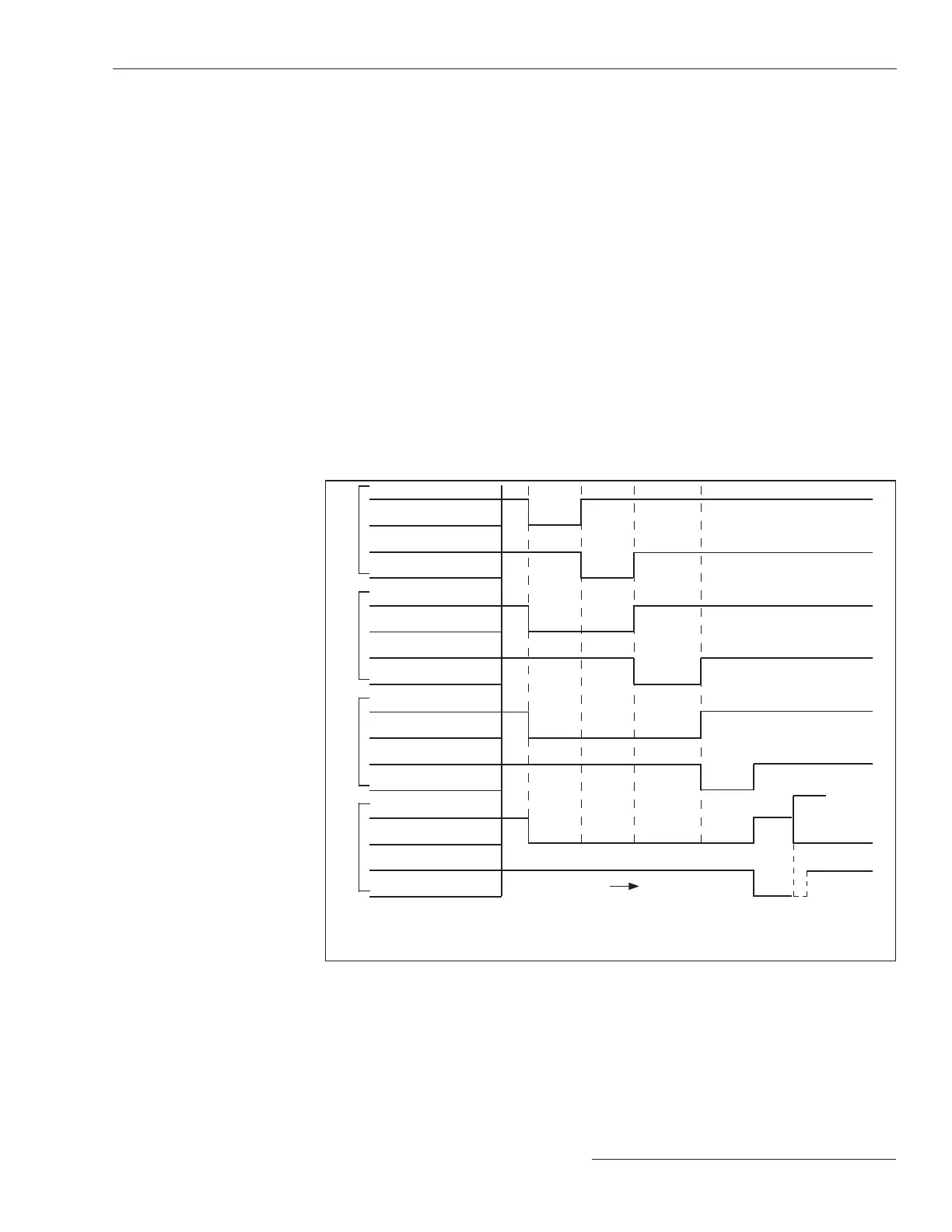

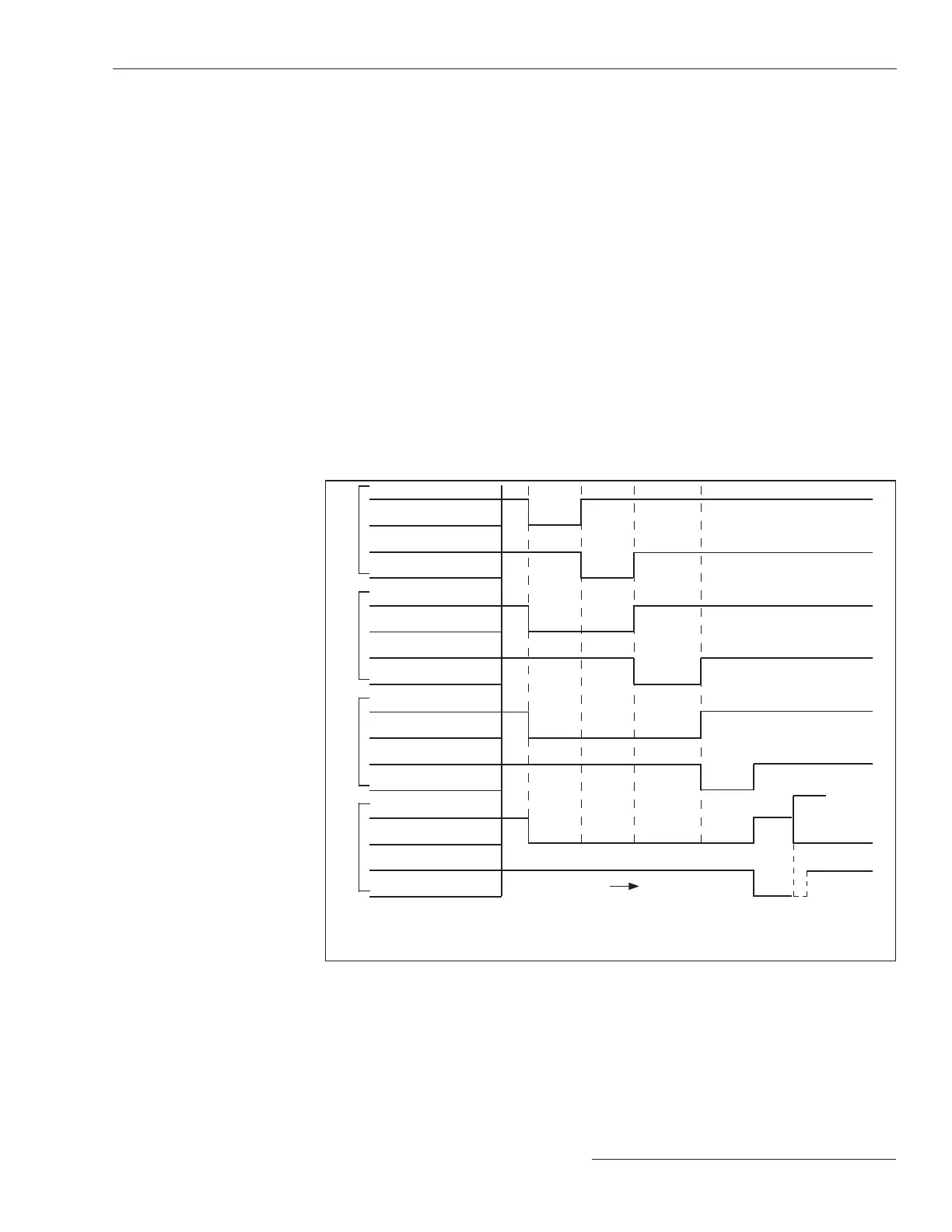

The timing diagram in Figure 39 shows the relationship between the Test-n Delay

Time setpoint on the Setup>Protection>General Profile n>Testing After Initial Trip

screen, the Test TCC Hold Time, and the Test Delay Time setpoints.

IR 4

IR 3

IR 2

IR 1

Closed

Open

P-TCC

Shift TCC

Closed

Open

P-TCC

Shift TCC

Closed

Open

P-TCC

Shift TCC

Closed

Open

P-TCC

Shift TCC

TnDT

TTHT

TnDT TDT

TTHT

TnDT No volt TDT

TTHT

TnDT No volt No volt

TDT

TTHT

Trip using

Shift TCC

time

Legend:

TnDT = Test-n Delay Time TTHT = Test TCC Hold Time

TDT = Test Delay Time

P-TCC = Previous TCC

Figure 39. The timing example for the PulseFinding technique with the TCC Shifting; the margin

setting is not accounted for.

Test Delay Time

This is the amount of time testing is delayed after the Good Source Voltage Indication

threshold has been met. This time applies to all test sequences. (Range: 0.3-300.1;

Step: 0.1; Default: 0.9)

Trip on Test Sequence TCC Low Cutoff

(Applies to both directions for this profile)

When checked, the TCC Shifting function performs an instantaneous trip whenever

the fault current reaches the Minimum Trip Level setting of any congured element

for the active Test Sequence TCCs before the Test TCC Hold Time setting expires.

The For Close Operations and the For Pulse Operations settings (see Figure 38 on

page 54) are all valid for the Trip on Test Sequence TCC Minimum Pickup function.

The Low Current Cutoff of the resulting TCC is the Instantaneous Trip Level setting

for the Test TCC Hold Time setting. When the Low Current Cutoff of the resulting TCC

is set to “N/A,” the Minimum Trip Level of the resulting TCC becomes the Instantaneous

Trip Level.

S&C Instruction Sheet 766-530 55

Protection Setup

Loading...

Loading...