Do you have a question about the Sartorius SIWRDCP and is the answer not in the manual?

Describes the purpose and target audience of the Signum® series compact scales.

Outlines the different weighing technologies and performance levels within the Signum® series.

Explains the meaning of symbols used throughout the operating instructions for clarity.

Guides on unpacking, acclimatization, checking geographical data for legal metrology, and under-scale weighing.

Instructions for connecting power, warm-up time, and connecting accessories like barcode scanners.

Details the procedure for correctly leveling the weighing platform for accurate measurements.

Identifies and describes the function of each key and display element on the Signum models.

Shows the location and purpose of the back panel connections like RS232 and power cord.

Explains how keys operate during measurement/configuration and details keypad input methods.

Describes input via digital control, ASCII ports, barcode scanners, and external keyboards.

Details the various symbols, bar graphs, and lines shown during weighing mode.

Explains meanings of symbols for applications, battery status, units, and tare values.

Identifies and explains each numbered element and symbol shown on the display during weighing.

Explains how application parameters and reference values are saved during weighing and after device power cycles.

Explains how to open, navigate submenus, and input data using alphanumeric and numeric methods.

Details how menu settings are saved, protected by password, and how to exit menus.

Explains how error messages are displayed, their causes, and corresponding solutions or actions.

Covers printer connectivity, digital I/O, communication interface, and how application parameters are backed up.

Details parameters for basic weighing, including minimum load, automatic taring, and tare function settings.

Covers minimum load, automatic taring, automatic start, resolution, and tare function for the Counting application.

Details parameters for neutral measurement, including minimum load, automatic taring, and resolution.

Covers minimum load, automatic taring, automatic start, and animal activity settings for averaging.

Details parameters for weighing in percent, including minimum load, automatic taring, and display of calculated values.

Covers minimum load, control output, activation of outputs, parameter input, and automatic printing for checkweighing.

Details parameters for classification, including minimum load, control output, activation of outputs, and number of classes.

Covers minimum load, automatic taring, individual/component printout, and saved value settings for net-total formulation.

Defines the functions that can be assigned to the FN key on Signum® 1 and Signum® 2 models.

Covers parameters for adapting the scale to ambient conditions, application filter, stability range, and delay.

Explains calibration, adjustment sequences, zeroing range, and preload settings for weighing platform 1.

Details settings for external calibration, calibration weight units, and entering calibration weight values.

Covers settings for interface port 1, including RS-232, SBI, XBPI, and ADC-232 protocols.

Details baud rate, parity, stop bits, handshake mode, and data bits for SBI standard version.

Configures automatic data output intervals and line format for raw data and other applications.

Option to restore factory default settings for the COM1 interface and SBI protocol.

Details baud rate settings for SMA interface and printer configurations for various models.

Explains printer configurations for YDP01IS, YDP02, YDP03, and YDP02IS models, including baud rates and parity.

Covers settings for universal interfaces (YDP04IS) and electronic memory (YAM01IS) for print data.

Details analog output settings for value, error indication, mode, min/max, and calibration values.

Details configuration for interface port 2, including weighing platform 2, RS-232, SBI, XBPI, ADC-232, and RS-485 protocols.

Explains how to connect Sartorius IS weighing platforms using RS-485 and ADC-485 interfaces.

Covers SBI standard version, XBPI, SMA interface, and Profibus settings for data transfer.

Details Ethernet settings including Source IP, Source Name, List Port, Subnet Mask, and Gate IP.

Details printer configurations for YDP01IS, YDP02, YDP03, YDP02IS, Uni-pri, YDP04IS, and YAM01IS.

Details analog output settings for value, error indication, mode, min/max, and calibration values.

Details the functions that can be assigned to external keys for universal input and specific Signum models.

Describes the settings for external output ports 1 through 5, indicating operational status like ready, stable, or overload.

Covers barcode input modes, storing values as reference or tare, and assigning ID codes.

Details header/ID input, quantity of printouts, configuration lists, and print item selection for interfaces.

Covers configuration lists for interface 2, GMP-compliant printouts, date/time settings, and automatic printing.

Details settings for flex print, decimal separator, and restoring factory settings for printout data.

Configures keypad lock, automatic display shutoff, display lighting, and timer settings for device operation.

Sets the main scale, displays geographical data before calibration, and restores factory settings.

Covers setting time, date, user password, SQmin display, and GLP header printout options.

Provides device information (service date, serial number, software version) and language selection for settings.

Explains the basic weighing function, including zeroing, taring, automatic taring, and automatic printing.

Details keypad locking, display lighting, automatic shutdown, and timer settings for device operation.

Explains the purpose of calibration/adjustment and how to configure scales for legal metrology use.

Covers using verified scales and the functions of the internal switch for service and verification access.

Details internal calibration procedures for SIWS models and how to set or delete preloads.

Explains how to display geographical data and provides notes on verified instruments and external adjustment.

Explains how to save reference weight, enter sample quantity/weight, and use ID codes and other features.

Details the tare function behavior and how to configure setup options like auto-taring and factory defaults.

Covers parameters for saving weight values, accuracy levels for piece weight calculation, and minimum load settings.

Explains minimum load requirements for initialization and auto-taring, and decimal place settings for display.

Details the criteria and process for automatically updating the reference sample weight during weighing.

Explains how to use two weighing platforms simultaneously for counting, including different operating modes.

Explains measuring length, surface, volume, saving reference weight, and using ID codes for neutral measurement.

Details the tare function behavior and setup options like auto-taring and factory defaults for neutral measurement.

Covers parameters for saving weight values, accuracy levels for reference weight calculation, and display decimal places.

Explains minimum load requirements and how to operate neutral measurement with one or two weighing platforms.

Explains averaging for unstable samples, manual/automatic start, info mode, and printout configuration.

Details the tare function and how to enter the number of subweighing operations for averaging.

Covers minimum load for initialization/taring and how averaging measurements are started manually or automatically.

Explains how the calculated average value is displayed and how to toggle between results and current weight.

Explains weighing in percent to obtain readouts proportional to a reference weight, including tare and initialization.

Details the tare function behavior and the three methods for entering reference values for weighing in percent.

Covers saving weight values based on stability, accuracy of piece weight calculation, and result display options.

Explains minimum load requirements and operating modes for weighing in percent with two platforms.

Explains checking samples against target values and tolerance ranges, including tare and initialization.

Details parameters like checkweighing range, control output, activation of outputs, and input methods.

Covers minimum load for taring/printing and how results are displayed as weight or relation to target.

Explains how the Checkweighing application supports digital I/O interfaces for control lines and outputs.

Explains determining sample weight within defined classes, including tare and initialization.

Details parameters like minimum load, control output, activation of outputs, number of classes, and input methods.

Covers minimum load for the first class and how results are displayed as weight or class number.

Explains the support for digital I/O interfaces and control lines for classification, including SET output.

Explains adding weight values to memory, saving values manually or automatically, and transaction counters.

Details the tare function behavior and setup options for totalizing, including restoring factory defaults.

Covers minimum load for autosave and auto-taring, and autosave mode settings for totalizing.

Details printout protocol configuration for manual or automatic printing and source of data for autosave.

Covers minimum load for autosave and taring, and operating modes for net-total formulation with two platforms.

Details how to save values manually and configure printout protocols for component records and total data.

Explains how to configure individual printout formats for each application, including list quantities and print items.

Details the preparation steps for configuring printouts, selecting items, and using additional functions like 'Form Feed'.

Explains the product data memory capacity, identification, and functions like saving, activating, and deleting data.

Details procedures for saving product data, preset tare values, activating saved data, and displaying memory contents.

Lists available options and protocols for the COM1 interface, including RS-232, SBI, XBPI, and printers.

Details UNICOM interface options like RS-232, RS-485/422, Ethernet, Profibus, and analog output.

Provides detailed pin assignments for COM1 and standard connectors, including keyboard and control outputs.

Shows SIWAEDG COM1 pin assignments and explains connecting a second weighing platform with different interfaces.

Explains SBI (ASCII) and SMA communication protocols, including data output configurations and commands.

Lists commands sent via the interface port to control scale functions, applications, and input data.

Details the formats for data output with 16 and 22 characters, including normal operation and special codes.

Explains how error messages are represented in the data output format and their corresponding meanings.

Defines ID code characters and their meanings, and explains how output values are displayed with specific resolutions.

Guides on connecting and configuring printers via COM and UniCOM interfaces, and actions that generate print commands.

Explains how to set up automatic weight readout printing based on display updates and scale stability.

Lists alphanumeric and function key codes for using a PC keyboard with Signum 2 and 3 for data input.

Covers cleaning procedures, replacing dust covers, safety inspections, and maintenance by authorized technicians.

Provides guidelines for the environmentally friendly disposal of the equipment, packaging, and batteries.

Lists general specifications like digital interface, display, dust/water protection, temperature range, and power supply.

Explains the model designation system, including sensor technology, material, application level, and capacity.

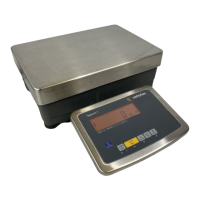

Lists specifications for SIWRDCP, SIWABBP, and SIWADCP models, covering capacity, readability, and resolution.

Details the different resolution codes and their meanings for Signum® Regular models.

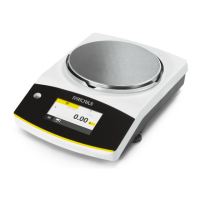

Provides detailed specifications for SIWADCP, SIWAEDG, SIWSBBP, and SIWSBBS models, including resolutions and accuracy classes.

Lists the various resolution codes and their verified factory types for Signum® Supreme models.

Lists specifications for SIWSDCP/S models, including capacity, readability, and preload values.

Shows scale drawings with dimensions for the Signum SIWAEDG model.

Provides scale drawings with dimensions in millimeters for SIWRDCP, SIWADCP, and SIWSDCP models.

Shows scale drawings with dimensions in millimeters for SIWABBP and SIWSBBP models.

Provides scale drawings with dimensions in millimeters for the SIWSBBS model.

Lists accessories for indicators and printers, including verifiable data printers and consumables like paper rolls.

Details available labels for specific printers and thermal paper rolls for different printer models.

Lists interface modules (UNICOM) and electrical accessories like barcode scanners, foot switches, and displays.

Covers software options for printouts and drivers, plus mechanical accessories like display support columns and brackets.

Lists various cables, plugs, and electrical accessories for connecting the scale and printers.

Details accessories specific to SIWAEDG models, including data output modules and connection cables.

Explains EC conformity marks, EMC directives, and European standards for electrical equipment and safety.

Covers requirements for legal metrology use, ATEX compliance for explosive atmospheres, and installation services.

| Readability | 0.01 g |

|---|---|

| Pan Size | 190 mm x 220 mm |

| Calibration | External |

| Protection Class | IP43 |

| Interface | RS-232 |