102(107)

6.2.1 Daily Maintenance and Adjustment of V-belt

Granulator is driven by 4 V-belt. The specification of the V-belt is XPA.

1) Inspect V-belt

After 20-30 hours of full-load operation, inspect the tension of V-belt and

running situation. Then, check the abrasion of belts every month.

2) Inspect the tension of V-belt every 6 months.

Loosen the screws which are on right shell and for fixing the electric control

box and then take out the upper cover plate of granulator. Turn the V-belt for

several circles to see whether the belt is damaged and worn.

Caution!

Do not put the hand between belt and belt pulley. Otherwise, the hand

may be jammed; inspect the tension of belt, and adjust it if necessary.

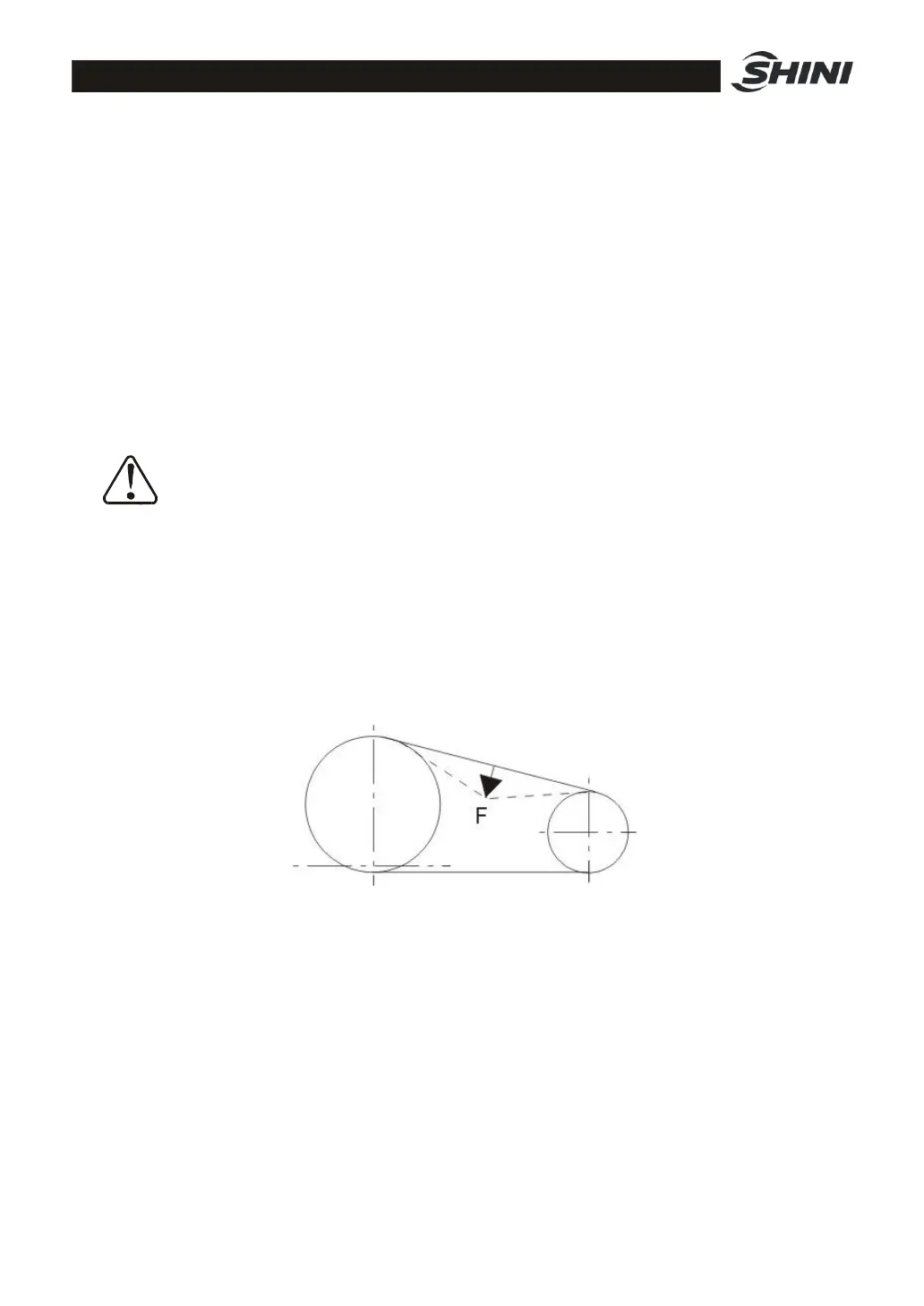

a) For motor of 7.5kW, press the belt which is between the two belt pulleys with

force of 205 N. The belt should not be stretched downward over 5mm.

b) For motor of 11kW, press the belt which is between the two belt pulleys with

force of 297N. The belt should not be stretched downward over 5mm.

Motor of 7.5kW L=5mm F=205N

For motor of 11kW L=5mm F=297N

Picture 6-2:Maintenance of Conveyor Belt

6.2.2 Adjustment of V-belt

1) Open the rear base plate of the granulator as well as the front door.

2) Loosen the screw handle and take out the storage box.

3) Adjust the two outer hexagon screws and adjust the belt tension by changing

the space between the big and small belt pulley.

Recheck the belt tension after 20-30 hours of full-load operation.

Loading...

Loading...