93(107)

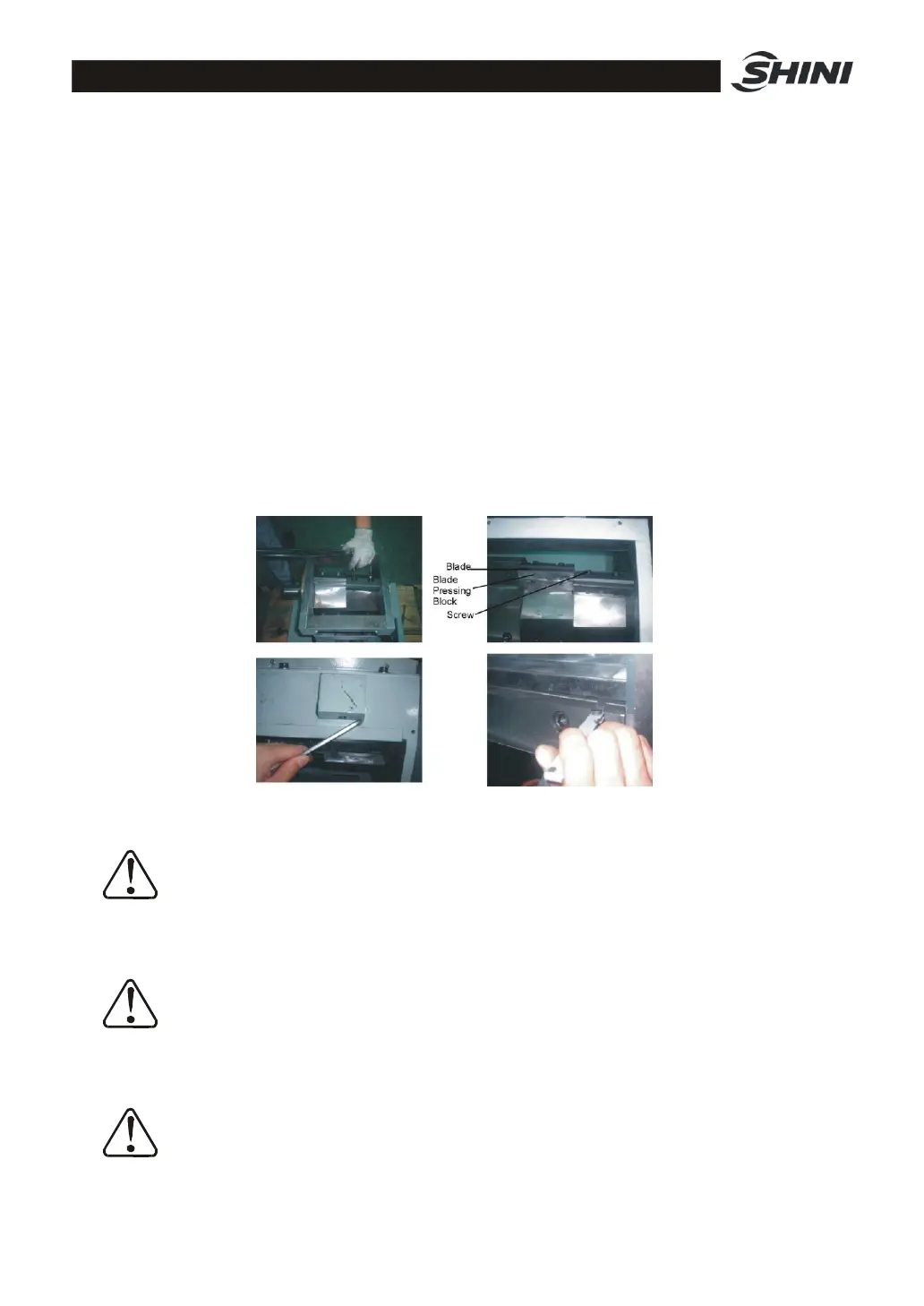

1) First, clean the front and rear box blocks as well as the press plate of rotary

blade.

2) Place the rotary blade into the groove; cover it with press plate and lock them

by screws.

3) Install the front and rear press plates of fixed blade respectively on front and

rear box block; reserve some clearance for fixed blades.

4) Put set screws into front and rear adjusting holes of fixed blade to easily drive

the fixed blade to adjust the clearance.

5) Place the clearance gauge between the fixed blade and rotary blade as well

as set the clearance to be 0.20~0.30mm (the clearance should not be too

small in case it damages the blades.)

6) After adjusting the clearance, lock the front and rear fixed blades tight.

Picture 3-11:Installation of Rotary Blade and Fixed Plate (4)

Note!

Srew specifications for fixed blades: inner hexagon M10 x 40 for SG-23

while M14 x 50 for SG-30; intensity: 12.9.

Note!

The fixing screws of blades must be tightened tight to avoid personal

injury and machine damage.

Note!

The clearance between blades should not be too small in case it

damages the blades.

Loading...

Loading...