Product Description (Details)

GM32 · Technical information · 8011923 · V1.4 · © SICK AG 15

Subject to change without notice

2.5.2.6 Summary

2.5.3 Events and signals output

2.5.3.1 Check cycle signals

The Not_measuring signal is active during the check cycle.

This signal can be sent via a digital output or read out via the OPC interface.

2.5.3.2 Maintenance request signal

The Maintenance_request signal is activated when an unallowed drift is determined or the

NO cell is empty

p. 13, §2.5.2) and, at the same time, an appropriate message entered in

the Logbook. The Maintenance_request signal can be sent via a digital output or read out

via the OPC interface.

2.5.3.3 Zero and reference point level output

The zero and reference point values determined can be output via the analog outputs. This

is done - depending on the parameter settings - directly after the check cycle or on demand

(via a digital input). The Output_control_values signal is active during output and can also

be sent via a digital output. The zero values are first output for 90 s and then the reference

values for 90 s. The Not_measuring signal is not active during the output.

As an alternative, the zero and reference values of the last check cycle can be read out

using SOPAS ET menu /Diagnosis/Check cycle.

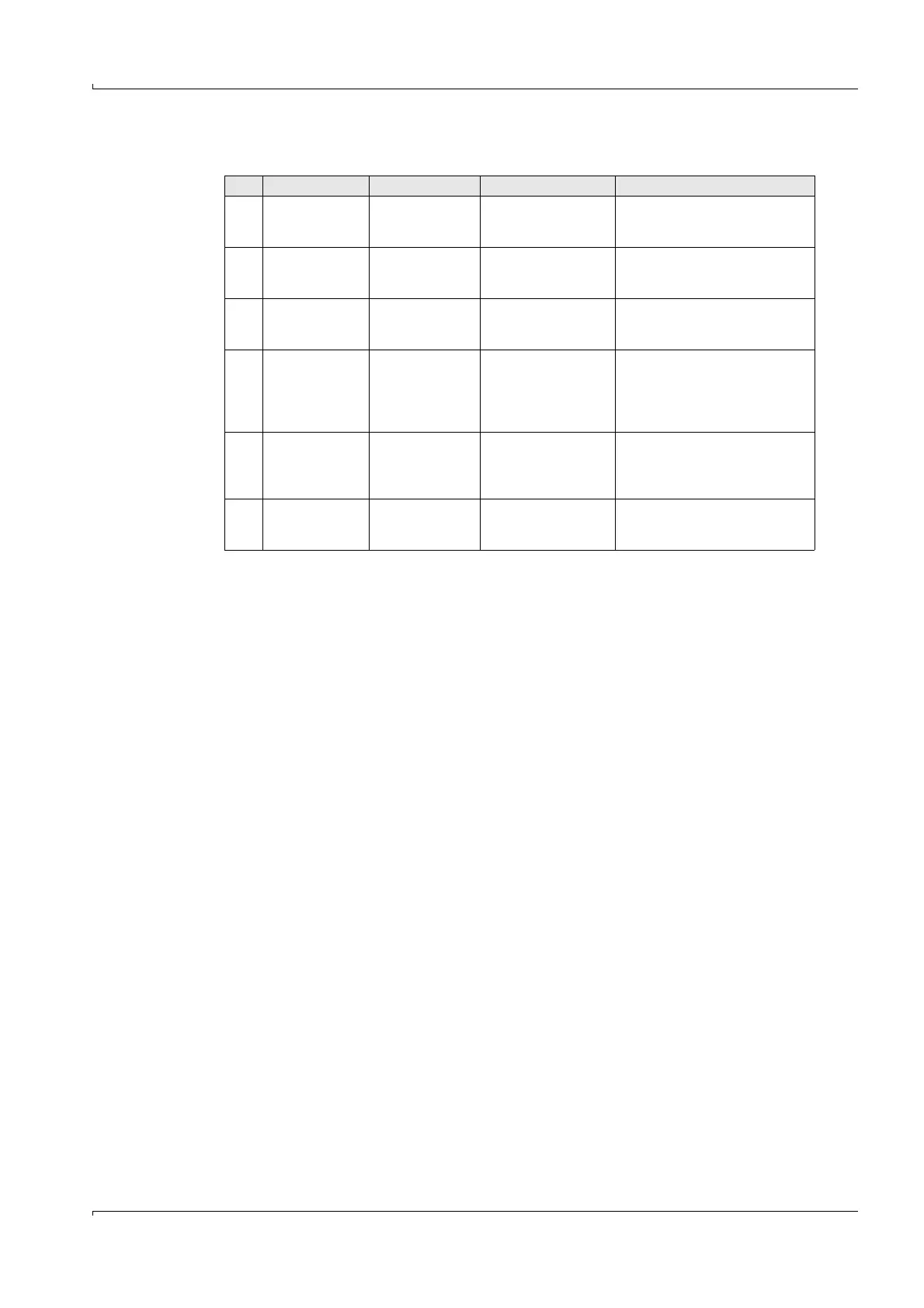

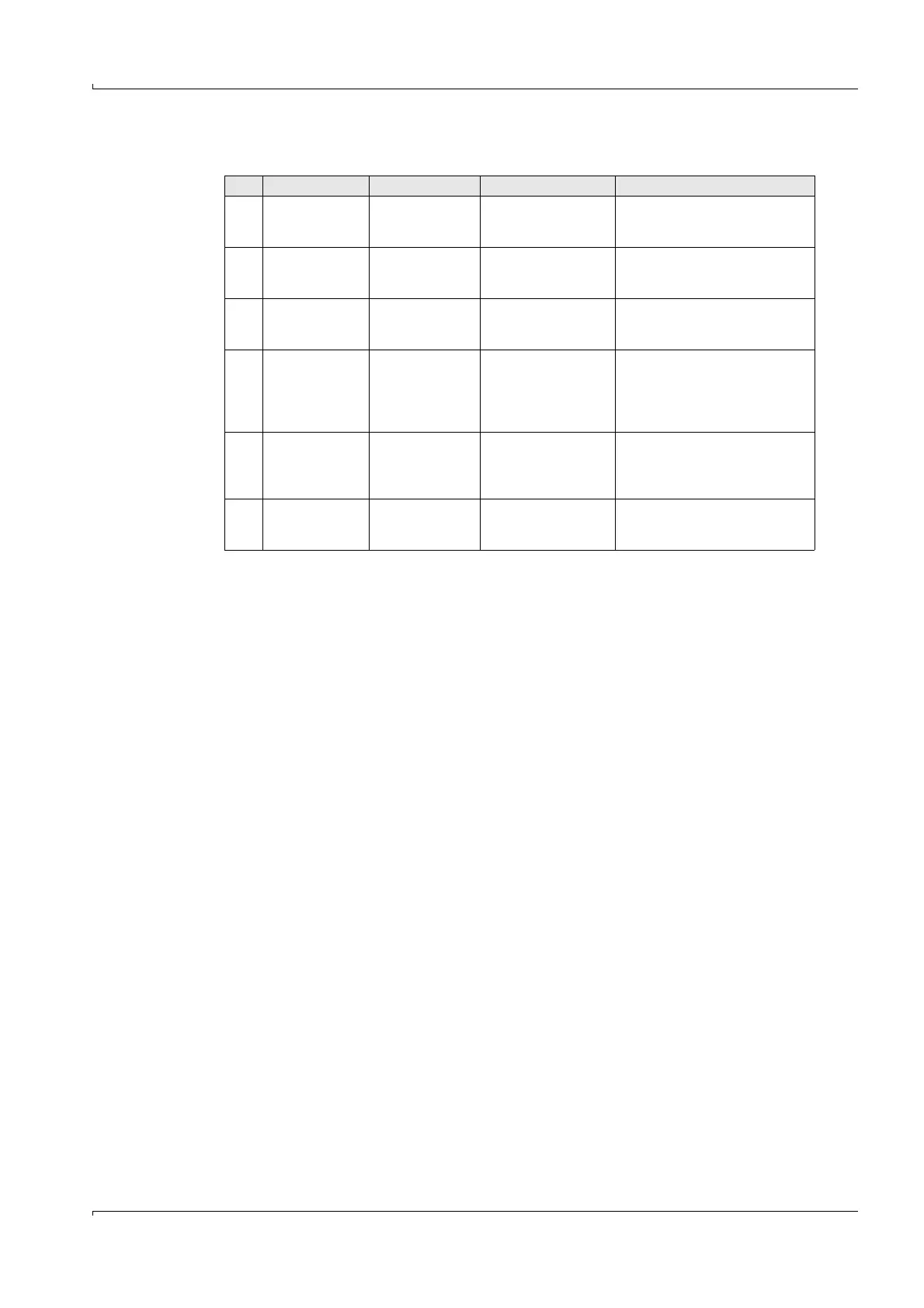

Table 1 Evaluation of data determined during the check cycle

Purpose Data used Evaluation Resulting action

1Check wave-

length scale over-

all drift

Current wave-

length scale

Determine shift of

wavelength scale

against scaling

Maintenance request signal when

shift above limit

2Check wave-

length drift

compensation

NO spectrum Determine NO peak

position

Maintenance request signal when

deviation from value against

scaling over limit

3 Check resolution NO spectrum Determine NO peak

width

Maintenance request signal when

deviation from value against

scaling over limit

4 Check absorption

scale

Grating filter spec-

tra

Grating filter absorp-

tion change relative to

scaling

Control value

1

output for individ-

ual components.

Maintenance request signal when

deviation from nominal value over

limit

1

Control value calculated as (70%+ grating absorption deviation in %) x FS

5 Check zero point Zero spectrum Evaluate zero spec-

trum with calibration

function

Zero value output for individual

components

Maintenance request signal when

deviation from zero over limit

6 Check cell filling NO spectrum Determine NO peak

height

Maintenance request signal when

peak height under 0.1 absorption

units

Loading...

Loading...