78 GM32 · Technical information · 8011923 · V 1.4 · © SICK AG

Maintenance

Subject to change without notice

5.3.2 Manual test gas feeding

1 Switch the GM32 to Maintenance (on the operator panel or in SOPAS ET menu: GM32/

Maintenance/Operating mode switch

p. 56, §4.2.6.1)

2 Connect the desired zero and/or test gas via pressure reducer to the probe (

p. 76,

Fig. 16).

3 Set the pressure gauge (

p. 77, §5.3.1) to the primary pressure determined.

4 If no further measurements are to be made: Set the GM32 back into measuring opera-

tion (on the operating console or in SOPAS ET menu: GM32/Maintenance/Operating

mode switch).

5.3.3 Using mixed gases as test gases

Safe mixed conditions:

WARNING: Hazard through escaping gases

Hot and/or noxious gases can escape during work on the test gas connection,

depending on the equipment conditions.

Test gases may only be applied by skilled persons who, based on their tech-

nical training and knowledge as well as knowledge of the relevant regula-

tions, can assess the tasks given and recognize the dangers involved.

Material required

SOPAS ET

Instrument air or N

2

Pressure gauge / pressure reducer

Supply line 1/4" with Swagelok fitting

Determine the test gas pressure again when the pressure in the gas duct

changes.

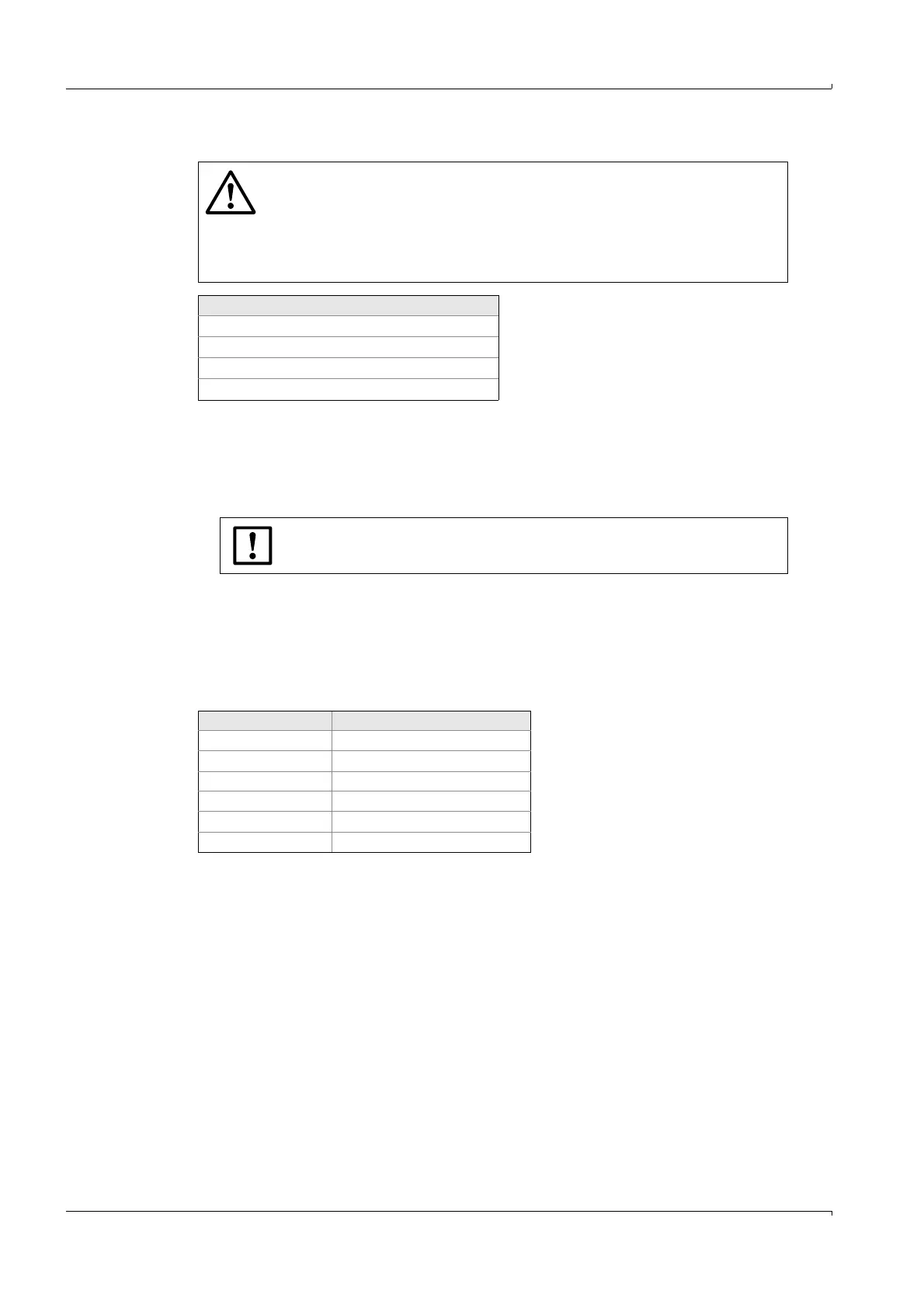

Mixed gas Safe mixed gas conditions

SO

2

+ NO > 10% NO included in SO

2

SO

2

+ NO

2

> 10% NO

2

included in SO

2

NO + SO

2

> 10% SO

2

included in NO

NO + NO

2

1

1

As far as available

> 25% NO

2

included in NO

NO

2

+ SO

2

> 50% SO

2

included in NO

2

NO

2

+ NO

1

> 10% NO included in NO

2

Loading...

Loading...