Important information

DANGER

D

angerous state of the machine

b

Make sure that the dangerous state of the machine is (and remains) switched off

during the alignment process.

b

Make sure that the outputs of the safety light curtain do not affect the machine

during the alignment process.

NOTE

Dur

ing the alignment, observe the alignment quality indication and the bracket that is

used to attach the twin sticks.

Further topics

•

"Ali

gning the twin sticks to one another", page 75

•

"Indication of the alignment quality", page 77

•

"Diagnostic LEDs", page 83

8.4.1 Aligning the twin sticks to one another

Overview

Af

ter the safety light curtain has been mounted and connected, the two twin sticks

must be aligned with each other. The beams of the sender optics must met exactly on

the receiver optics.

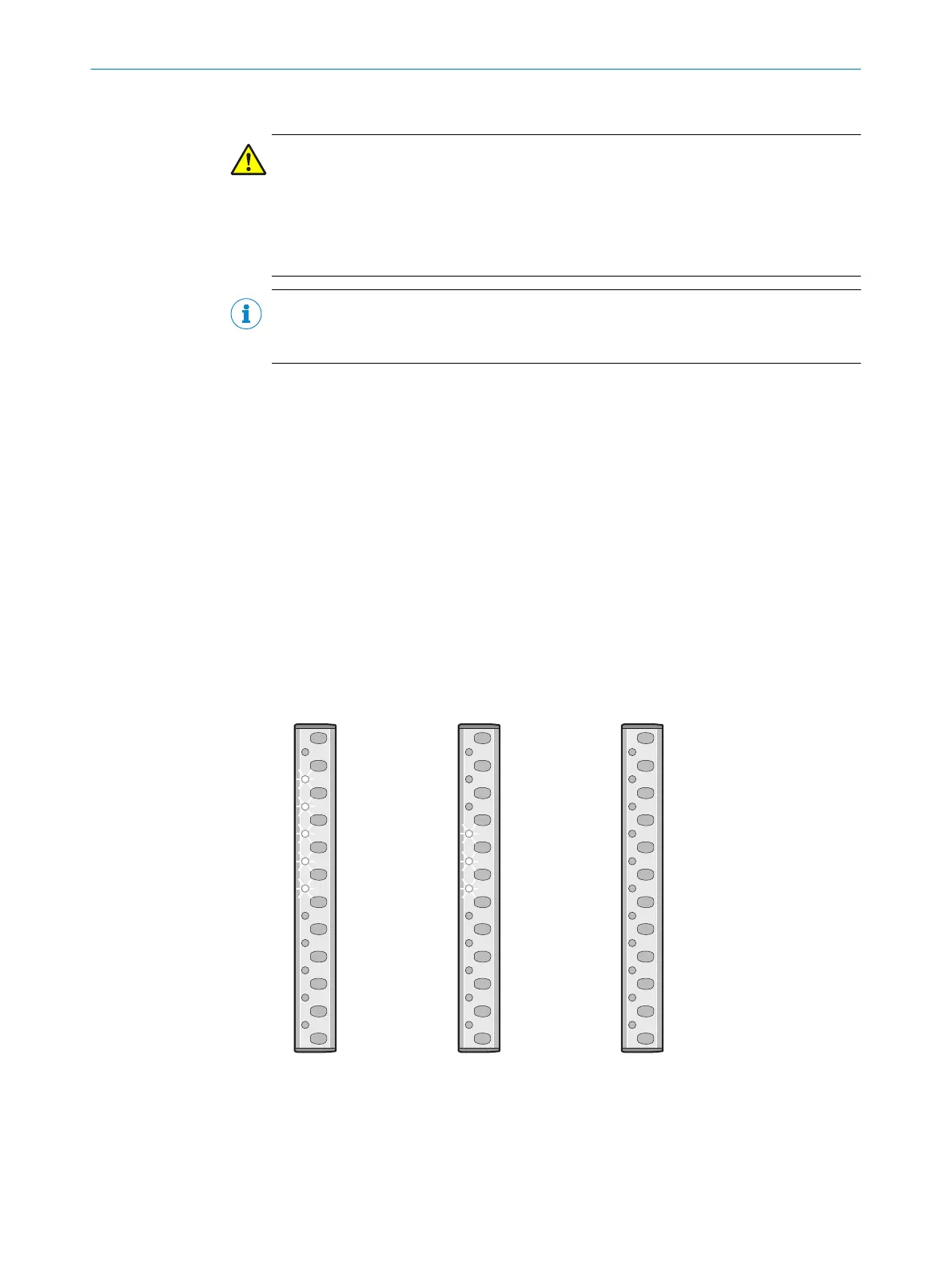

The miniTwin4 safety light curtain signals the alignment quality with the blue LEDs (1 to

5), i.e. how well the two twin sticks are aligned with each other. If all LEDs light up, then

alignment is optimal; if no LEDs light up, alignment is poor.

If 3 of the blue LEDs light up, the safety light curtain switches to green. From this point

in time, you have about 2 minutes to optimize the alignment of the twin stick.

! " §

LED 1, 2, 3, 4, 5

LED 1, 2, 3

Figure 62: Alignment of the safety light curtain

!

Optimal alignment

"

Sufficient alignment

§

Insufficient alignment

COMMISSIONING 8

8012624/10OM/2018-08-09 | SICK O P E R A T I N G I N S T R U C T I O N S | miniTwin4

75

Subject to change without notice

Loading...

Loading...