3.

To confirm the digit and move to the next digit, press the pushbutton.

✓

Next digit flashing.

4. Set the other digits as described.

5.

To return to the previous digit, press the pushbutton.

6.

Set the last digit. Confirm the entry with the pushbutton.

✓

The value for the parameter is set.

7.

To return to the measured value display, press the pushbutton until the meas‐

ured value is displayed.

Further topics

•

Display and control elements

7.1.5 Activating and deactivating the operating button lock

To prevent accidental operation, lock and unlock the operating pushbutton using a

shortcut.

►

Press and hold the and pushbuttons simultaneously for >3seconds.

✓

When the pushbutton lock is activated, Lock appears in the display. When the

pushbutton lock is deactivated, Unlock appears in the display.

7.2 Operation via IO-Link

The device can exchange process data and parameters via IO-Link. To do this, connect

the device to a suitable IO-Link master.

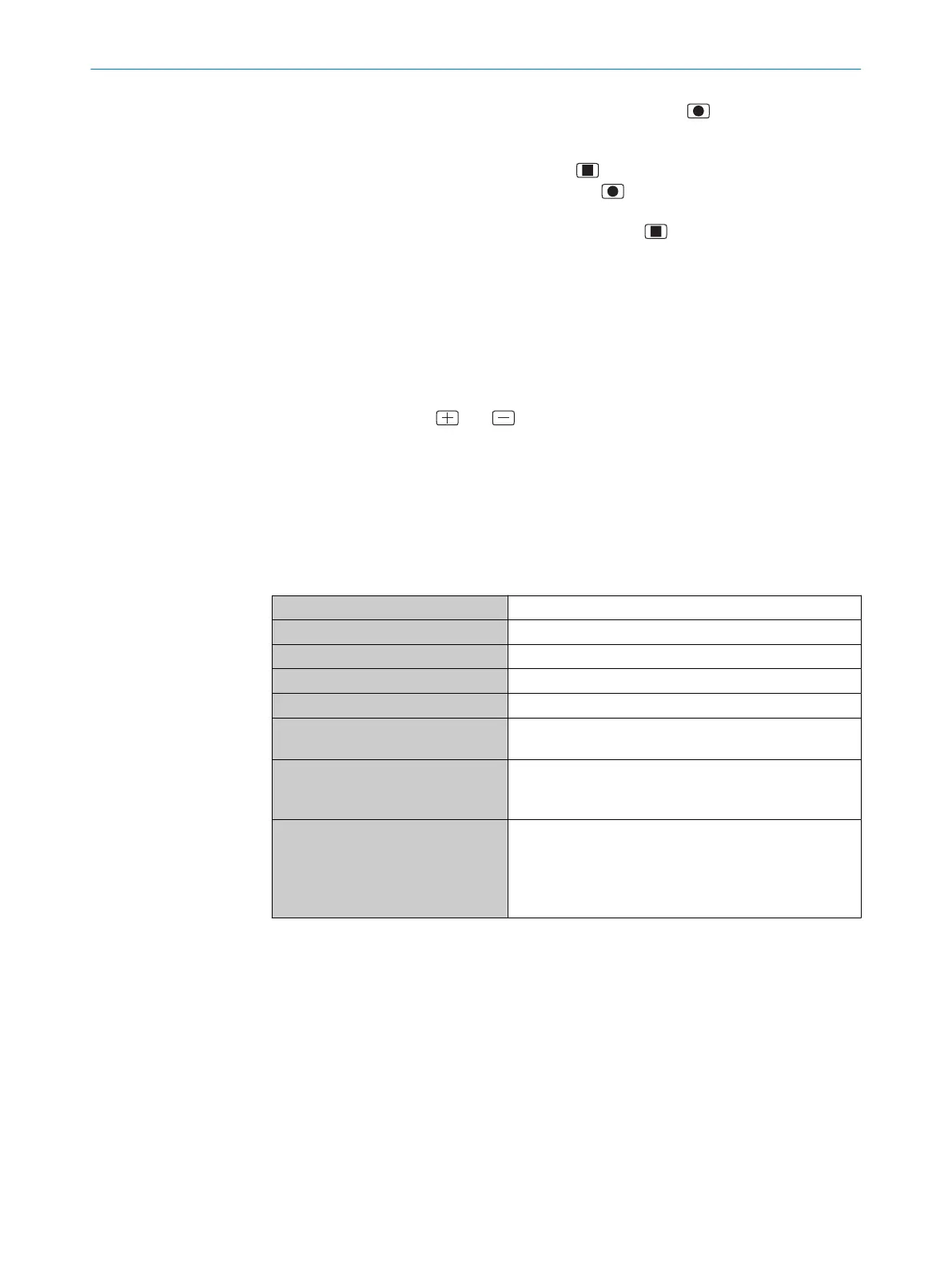

Table 4: Properties of the IO-Link interface

IO-Link specification V 1.1

Minimum cycle time 0.7ms (COM3)

Transmission rate COM3 (230.4kBaud)

Process data width 48bit outgoing (from device to master)

Process data type Record

Parameter configuration server func‐

tion (data storage)

Yes

Profile type SSP 3.2, 0x000B, Measuring Sensor high resolution

(DMS)

0x4000, Identification and Diagnosis

Function class 0x800B, Measurement Data Channel, (high resolution)

0x8000, DeviceIdentification

0x8002, ProcessDataMapping

0x8003, DeviceDiagnosis

0x8100, ExtendedIdentification

7.2.1 Process data

Data of the process data telegram (factory setting)

•

Measured distance value (unit: nanometer, 32bit with sign)

•

Status Q1 (1bit)

•

Status Q2/Q

A

(1bit)

The process data format and the offset for the distance value can be changed by

parameterizing the device.

OPERATION 7

8026231/1I18/2023-01-05 | SICK O P E R A T I N G I N S T R U C T I O N S | OD2000

23

Subject to change without notice

Loading...

Loading...