3 SYSTEM DESCRIPTION

8022965-17I6/2020-03-19|SICK

ORIGINAL OPERATING INSTRUCTIONS| VMS4200/5200 (Multicontroller)

Subject to change without notice

3.6.5 Test instructions for market surveillance

This chapter describes the procedure for inspecting the certified VMS5200

(Multicontroller) measurement system with regard to:

• The performance of metrological measurements with defined test objects and the

display of the measurement results on the LFT display.

• The display of data sets stored in the alibi memory on the LFT display.

• The display of system component firmware versions via the LFT display.

▸

Establish the voltage supply to the devices via the power supply unit in the cabinet.

• All system components start up automatically and are then ready for use.

• The MEASUREMENT tab is active in the menu bar. No measured values are available

yet.

▸

Measure test objects made from a dimensionally stable material of various shapes and

surface qualities.

▸

Perform the measurements.

NOTE! The nominal dimensions (length, width, height) must cover approximately 90%,

50%, and 10% of the total measuring range for each dimension. The actual dimensions

must not be less than the minimum dimensions or exceed the maximum dimensions

specified for the VMS5200 (Multicontroller).

▸

Ensure that the required minimum distance of 50 mm is maintained between the test

objects.

▸

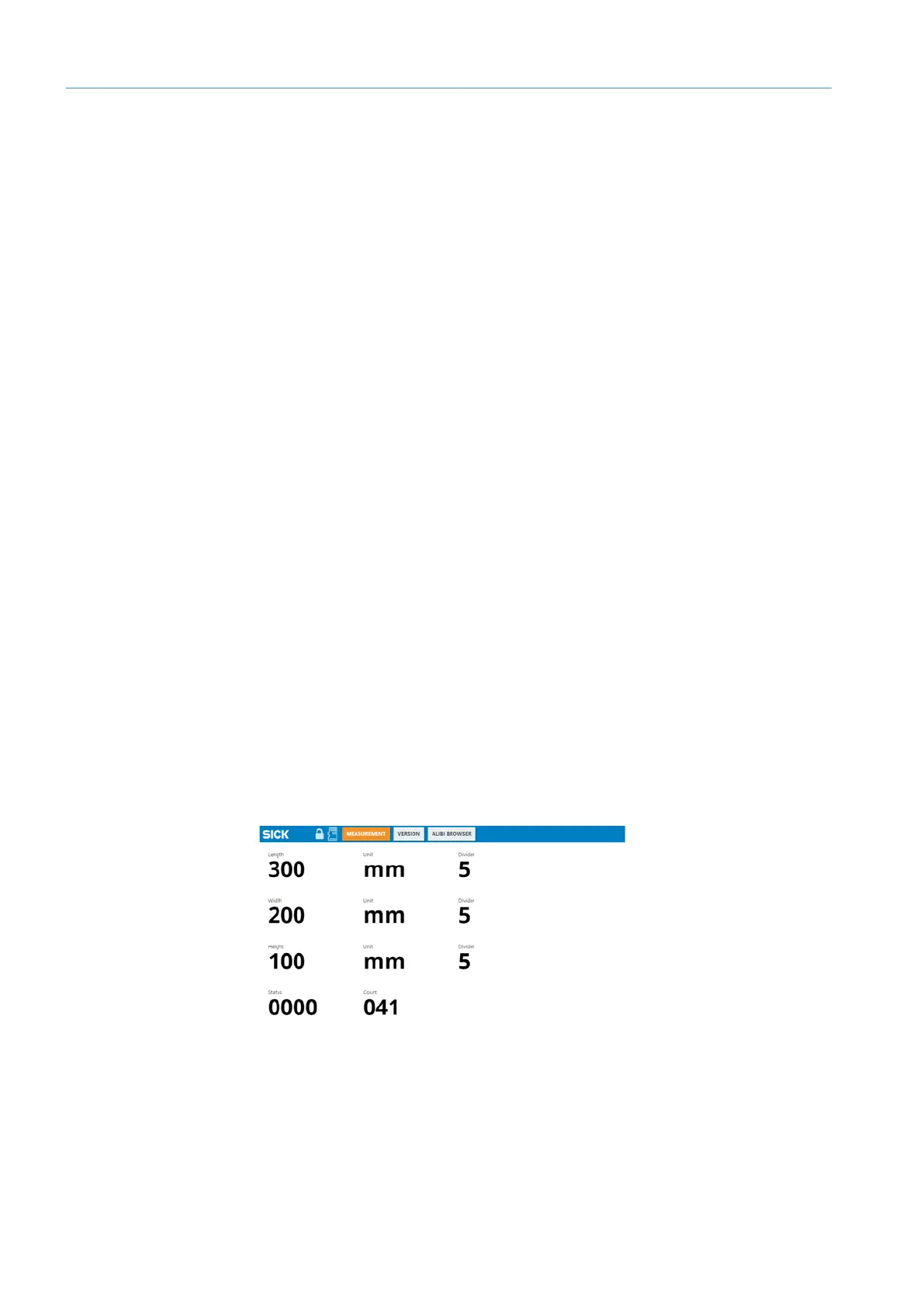

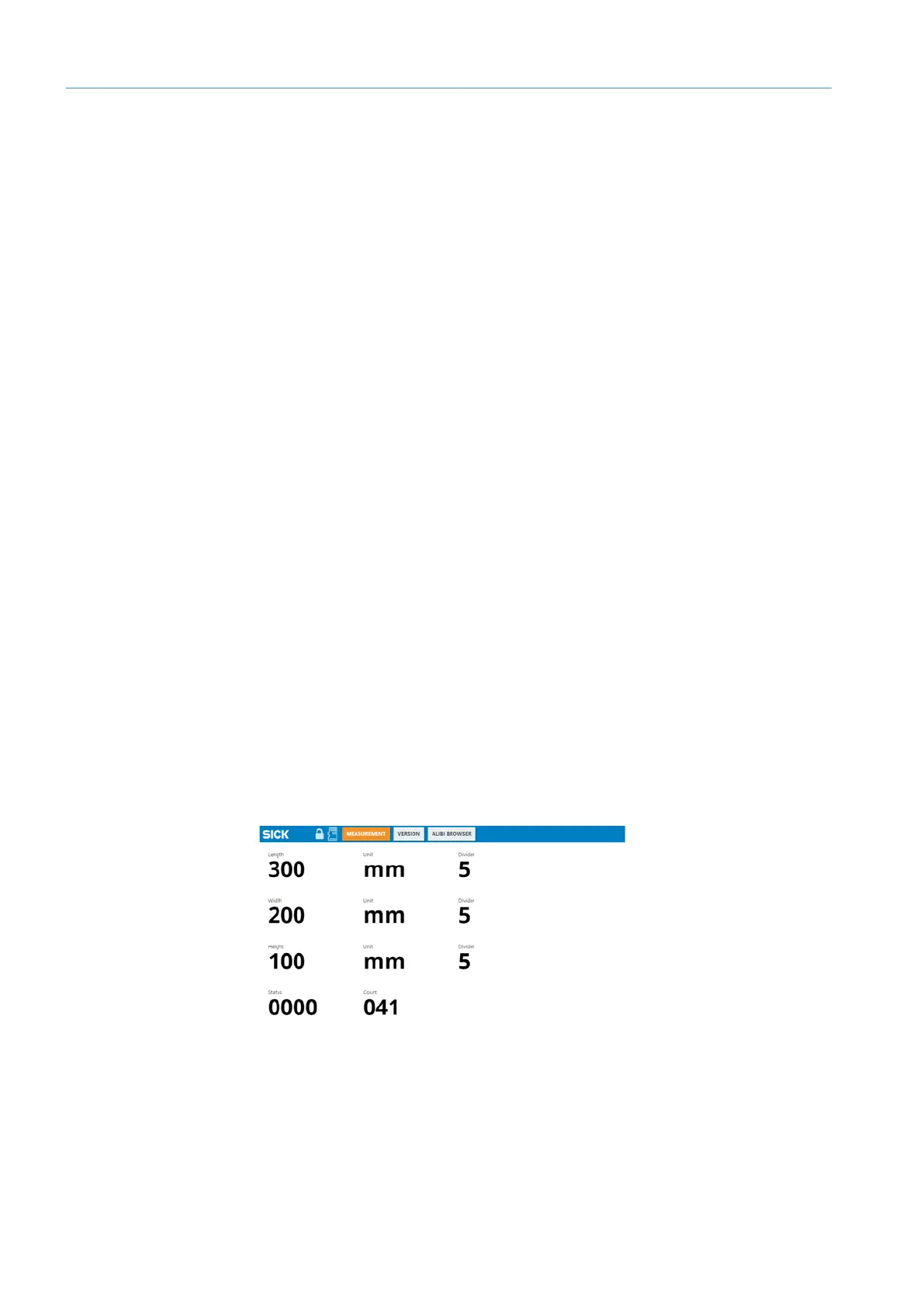

Compare the actual values for each measured test object with the dimensional values

on the LFT display.

NOTE!

• Valid measurement results have the status 0 0 0 0. They are LFT-verified and can

be used for billing.

• The Refresh Counter display (041 in the image below) is not legally relevant and

therefore not included in the alibi data.

Starting the

system

Measuring

test objects

Loading...

Loading...