The drive control supports servo control (for a highly dynamic response), vector control (for

maximum torque accuracy) and

V/f

control.

Note

With

the SIZER configuration tool, you can easily configure the SINAMICS S120 drive family

including SIMOTION.

It provides you with support for selecting and dimensioning the components required for a

motion control task.

You can also determine the possible number of axes and the resulting load with SIZER in

accordance with your performance requirements.

Hardware components

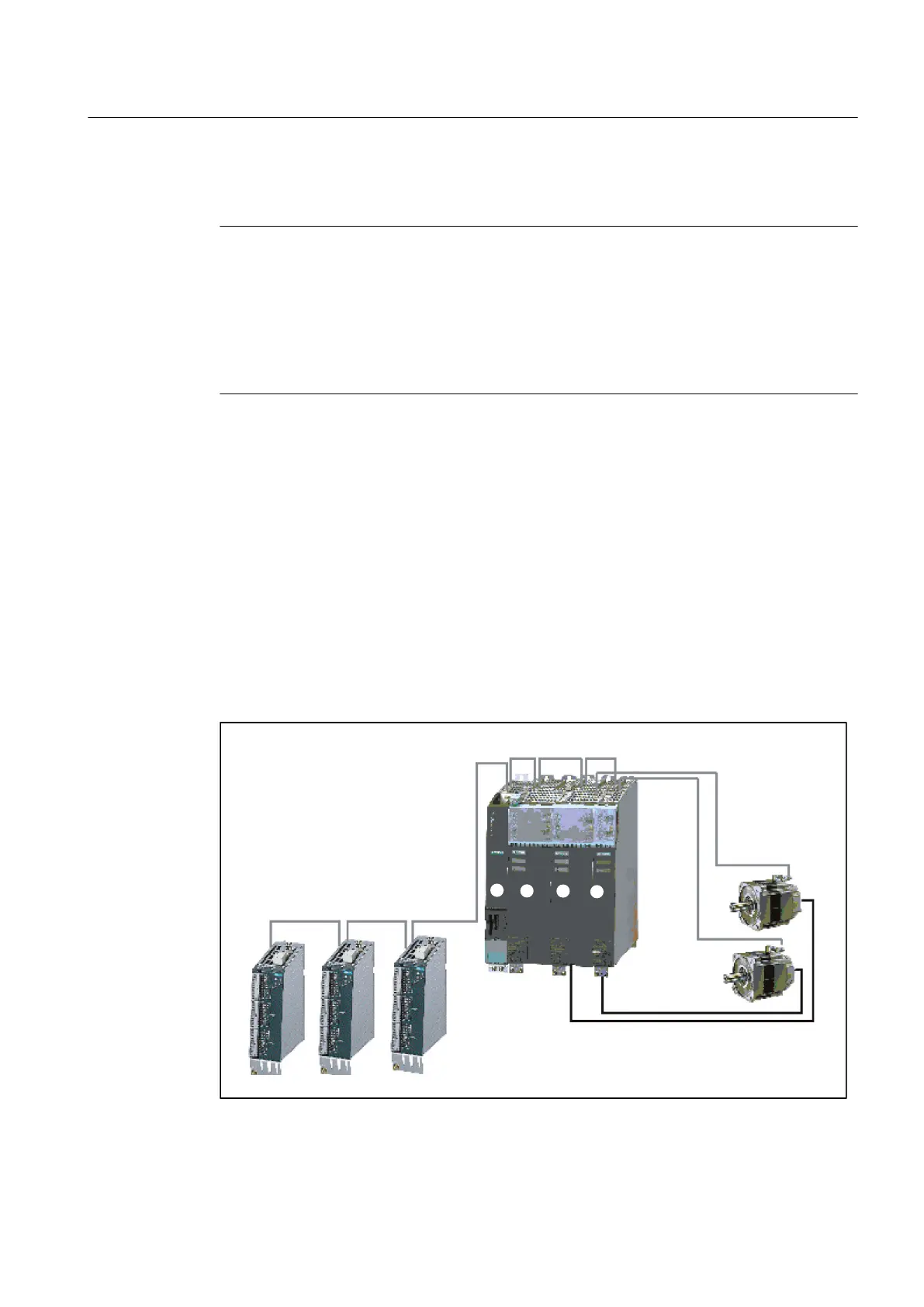

As

the central hardware, SIMOTION D uses the SIMOTION D4x5 as a Control Unit consisting

of the SIMOTION runtime system and the SINAMICS drive control. The Control Unit uses the

SINAMICS Integrated drive with various SINAMICS S120 drive modules (line and motor

modules) to perform open-loop and closed-loop control of the axis grouping. A range of

additional SINAMICS S120 components, such as SMx encoder systems or terminal modules

can be connected via DRIVE‑CLiQ. With a few exceptions (e.g. no basic positioner EPOS, no

basic operator panel BOP20, etc.), the drive control integrated in SIMOTION D has the same

control characteristics and performance features as the SINAMICS S120 CU320 Control Unit.

The EPOS functionality is provided by the SIMOTION technology functions. The functionality

of SIMOTION D can be expanded with the distributed I/O via PROFIBUS or with the CBE30

Ethernet communication board via PROFINET IO.

The following figure shows a typical SIMOTION D axis grouping.

'5,9(&/L4,2GHYLFHV

7HUPLQDOPRGXOHV

'5,9(&/L4

'5,9(&/L4

3RZHU

ᆰ

ᆱ

ᆲ

ᆲ

ᆳ

ᆳ

Figure 2-1 Example of a SIMOTION D4x5 axis assembly

Description

2.1 System overview

SIMOTION D4x5

Manual, 04/2014 21

Loading...

Loading...