06.03

10.6 Digital and analog I/O devices

10-384

Siemens AG, 2003. All rights reserved

SINUMERIK 840Di Manual (HBI) – 06.03 Edition

R Computational time of position controller and/or signal module

Dx User data exchange between DP master and DP slaves

MSG Acyclic services (e.g. DP/V1, token transfer)

RES Reserve: “active break” until the equidistant cycle has elapsed

1

Set the system variables, e.g. $A_OUT[8] in the parts program or

synchronized action

2

Transmit the output signal to the signal module on

PROFIBUS DP

3

Connect the signal to the output of the module.

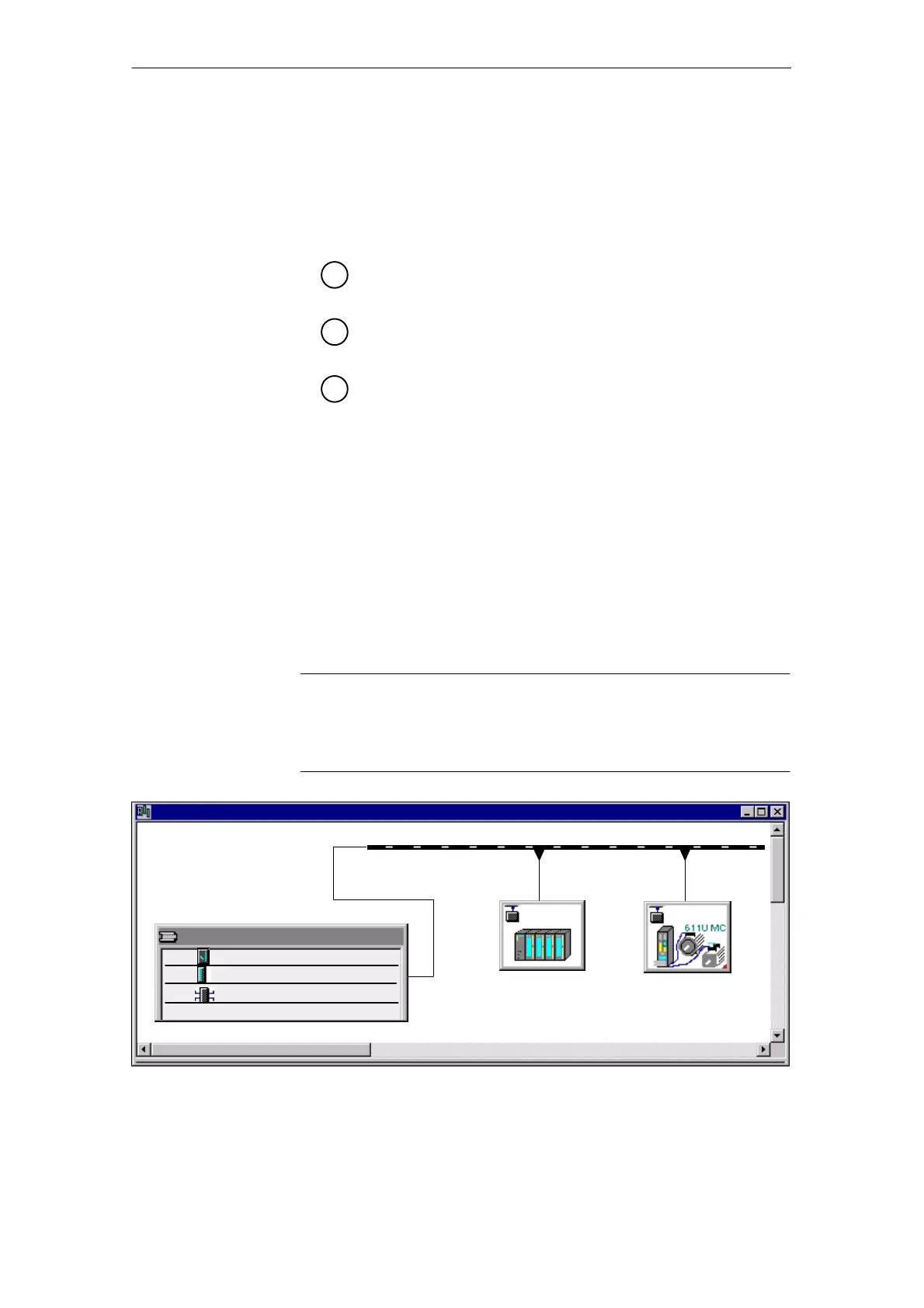

10.6.6 Configuration example

In the following configuration example the following input/outputs are available

to the NC:

ET200

– 24 digital inputs

– 16 digital outputs

ADI4

– 8 digital inputs

– 16 digital outputs

Note

The I/O addresses of the modules are assigned automatically by “HW Con-

fig”. (Manual adjustment is possible.)

Each I/O address refers to an input/output byte.

PROFIBUS(2): DP master system (2)

840Di (configuration) –– 840Di_ET200_ADI4

(0) 840Di

(0) UR

X2

PLC315-2DP M/S 2AF03

DP Master

2

4

CP 342–5

(5) IM 153 (6) ADI4

Fig. 10-35 Example configuration: SINUMERIK 840Di with ET200 and ADI4

10 NC Start-U

with HMI Advanced

Loading...

Loading...