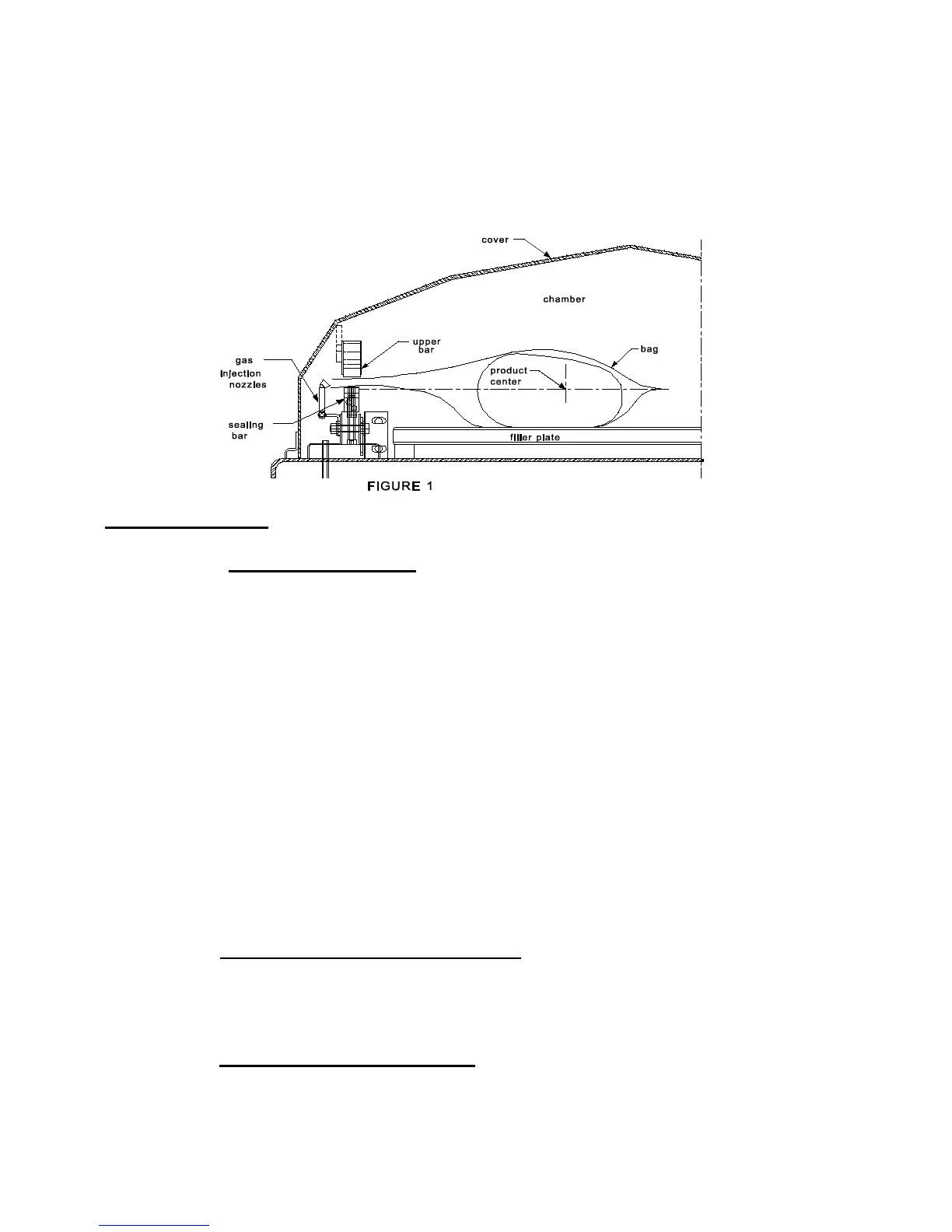

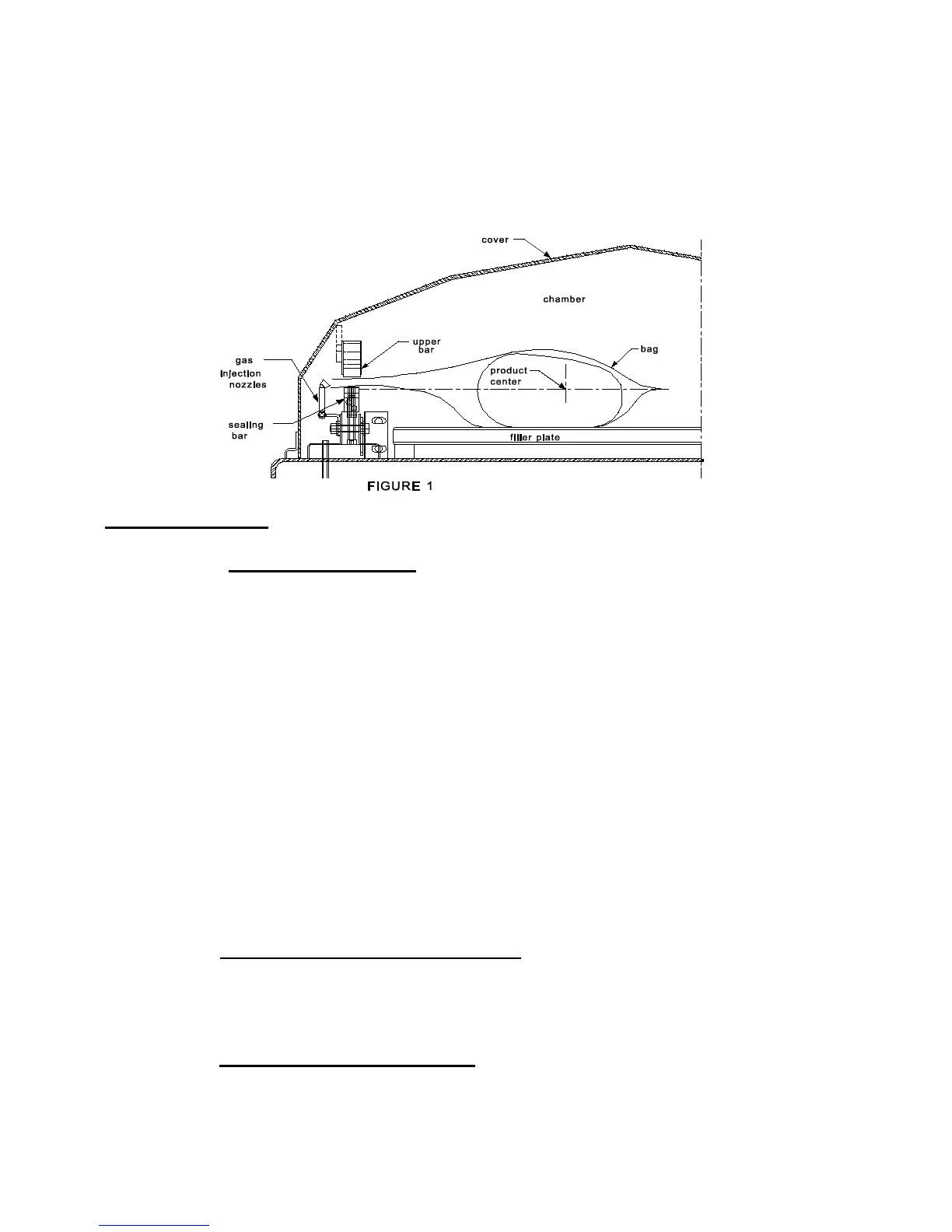

To obtain nice packages, the products and the bags have to be of proportional sizes. The

bag's opening should never exceed 50 cm(2") past the seal bars. The product should be

centered in height in relation to the seal bar by adjusting the spacers provided.

To obtain a good seal, make sure that no residue of fat is left between the bag's inner

sides where sealing is done.

3.2 Special packaging:

3.2.1 Gas flushing (option):

There is an atmospheric pressure of 1 kg/ sq. cm (14 lbs/sq. inch) upon products when

fully evacuated. Products which can be damaged by high pressure must be packaged

with a partial vacuum, or the pressure must be counterbalance by inflating the bag with

gas (nitrogen or carbon dioxide) before sealing after evacuation.

For gas flushing, the bags are placed on the sealing bars, the open end placed over

the gas nozzles mounted alongside the sealing bar. After evacuation, the vacuum

valve closes and the gas valve opens. Gas time (sec.) can be set in the program

menu.

The necessary gas tank and pressure valve mounted on tank is not supplied, The

pressure of the gas regulator should be set at approximately 1/3 kg/sq. cm

( 5 lbs/sq.inch.). Each machine has an adaptor for gas connection when gas flush

option is ordered.

3.2.2 Top and bottom sealing (optional):

When sealing aluminium laminate bags (especially bags for e.g. coffee) it is imperative

to have an upper and a lower sealing bar.

3.2.2 Electrical bag cut (optional):

This option is used to obtain a package that the excess bagtail is cut off close to the

seal (cannot be used with top and bottom sealing).

Loading...

Loading...