22

SJ1044 TH, SJ1044 THS, SJ1056 TH, SJ1056 THS, SJ1256 THS

230790ABA

Section 1 – Scheduled Maintenance Scheduled Maintenance Inspections

1.5-11 Grease Fittings - B

▪

Maintaining properly greased components is

essential for good performance and service life

of the telehandler. If components are improperly

greased, it could result in component damage.

Refer to section 5.2 for greasing procedures.

WARNING

Ensure that there are no personnel or obstructions

in maintenance area.

▪

Greasing intervals are based on average

telehandler usage. Use of telehandler may vary

significantly and greasing frequency must be

adjusted to obtain maximum service life.

▪

Refer to the Daily and Weekly Maintenance

Chart located inside operator’s cab for grease

points location and service intervals.

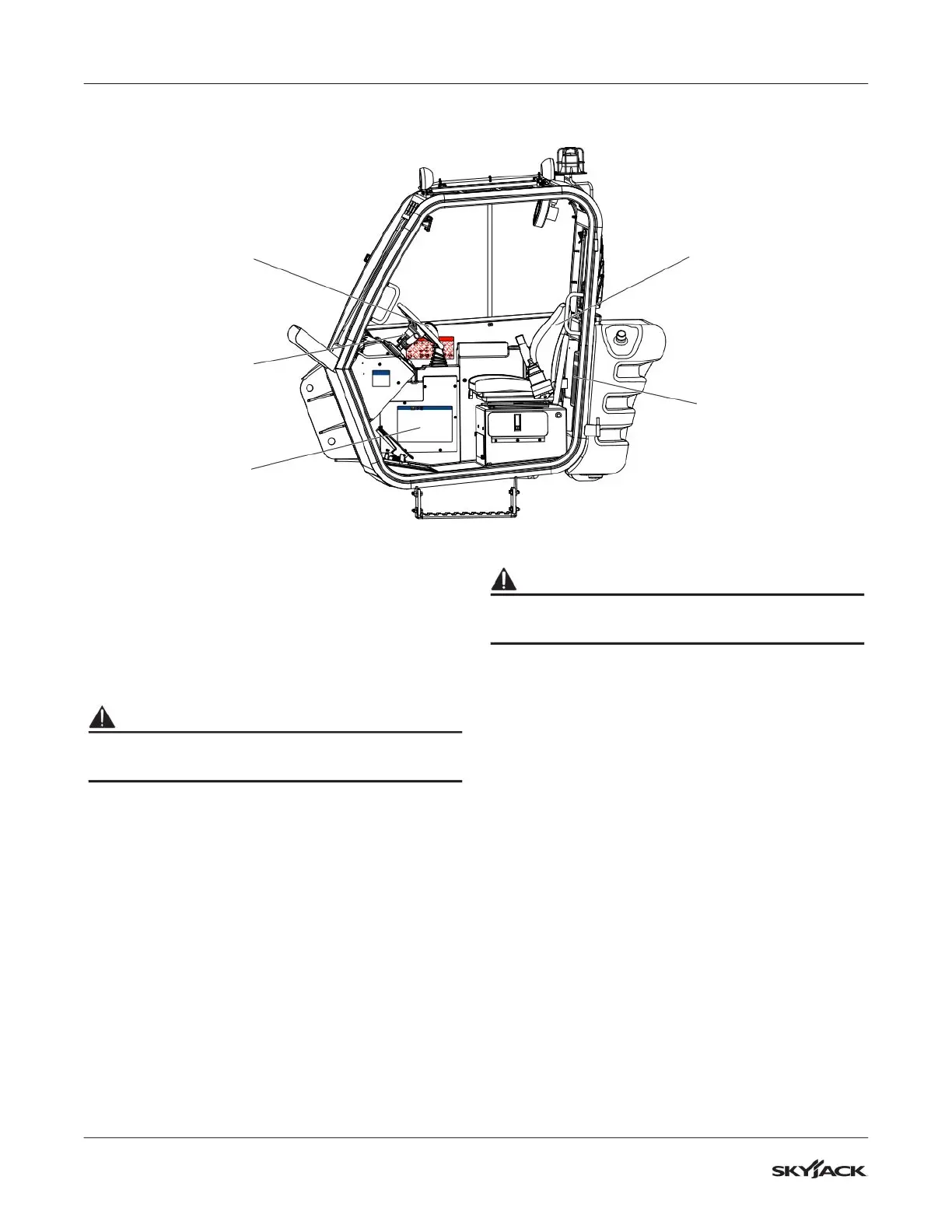

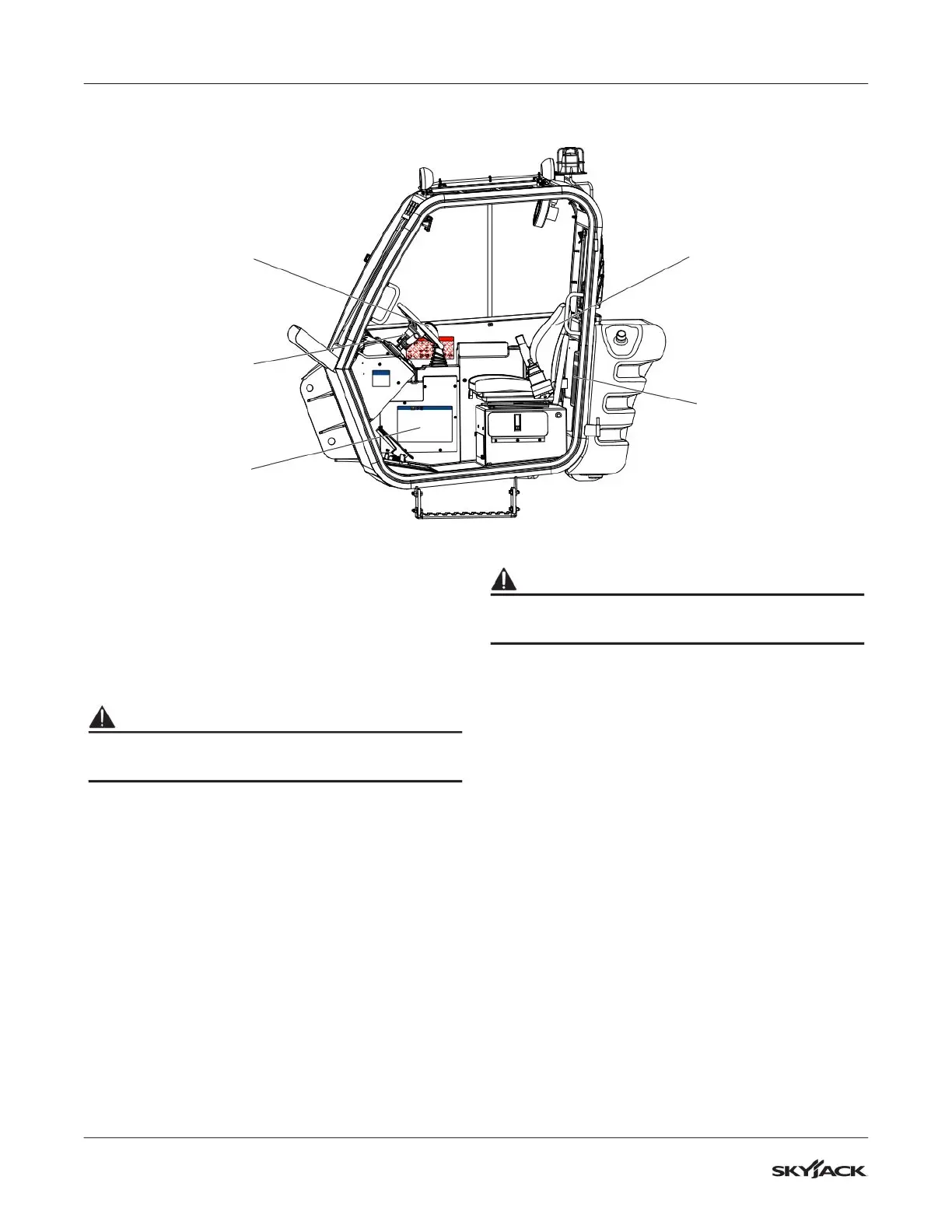

1.5-12 Operator’s Cab

▪

Rollover and Falling Object Protective

Structure (ROPS/FOPS) - B

▪

Ensure there is no visible damage.

WARNING

Do not modify, drill or alter the operator’s cab in

any way.

▪

Seat - A

▪

Ensure seat is properly secured with no sign of

visible damage.

▪

Ensure seat belt is working properly with no

sign of visible damage.

▪

Pedals - A

▪

Ensure brake and accelerator pedals are

secure, no loose or missing parts, no sign

of visible damage and movements are not

obstructed.

▪

Manual - A

▪

Check to be sure manual storage box is present

and in good condition.

▪

Ensure a copy of operating manual, and other

important documentation are enclosed in

manual storage box.

▪

Ensure manual is legible and in good condition.

▪

Always return manual to the manual storage

box after use.

10h / 50h

Operator’s Cab

Multi-Function

Joystick

Transmission

Shifter

Operator’s

Seat

Manual

Storage Box

Daily & Weekly

Maintenance Chart

Loading...

Loading...