175

SJ1044 TH, SJ1044 THS, SJ1056 TH, SJ1056 THS, SJ1256 THS

230790ABA

Non-Routine Maintenance Section 5 – Procedures

5.6-5 Hydraulic Pump Testing Procedure

If the hydraulic pump is suspected to be bad, the

following test will quickly determine if the hydraulic

pump requires replacement.

1. Release residual pressure by moving the joystick

several times in each direction

2. Remove LS hose on the main manifold and cap

the fitting on the manifold.

3. Install a 5,000 psi gauge with a tee fitting on the

GP1 port of the main manifold.

4. Install the LS hose to the tee fitting on the GP1.

LS Port to

Port X on

Hyd. Pump

To Port X on

Hyd. Pump

LS Port

GP1

Connect

Pressure

Gauge

Figure 111 Pump Pressure Adjustment

5. Start the engine and check the gauge. Maximum

system pressure should immediately be present

(3,250 psi).

6. If the pressure reading is different than the

required pressure, use the pressure adjustment

screw on the pump to adjust the pressure to the

proper level.

7. If the required pressure cannot be set, the pump

must be replaced.

5.6-6 T12000 Modulation

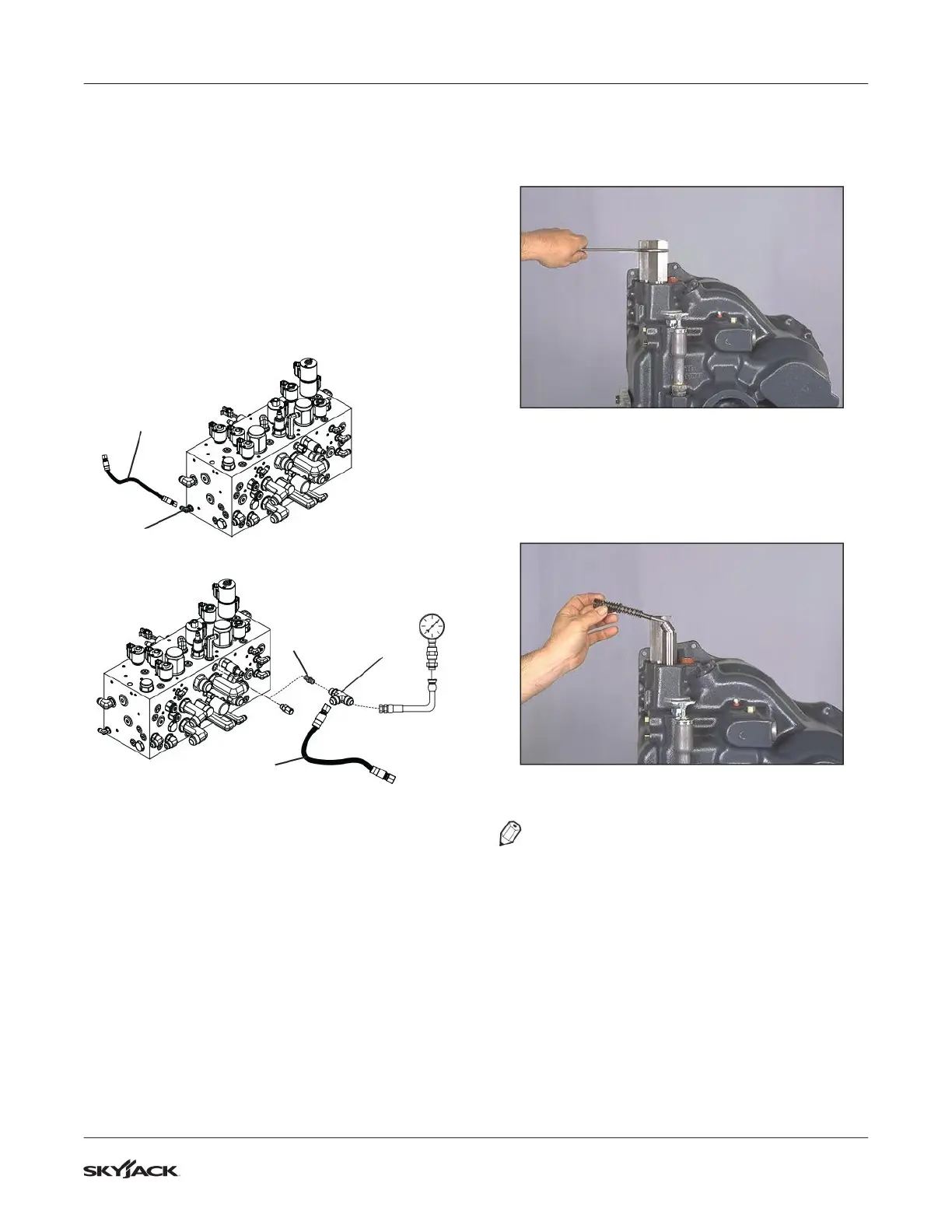

1. Remove modulator valve housing as shown in

figure below.

Figure 112 Remove Modulator Valve Housing

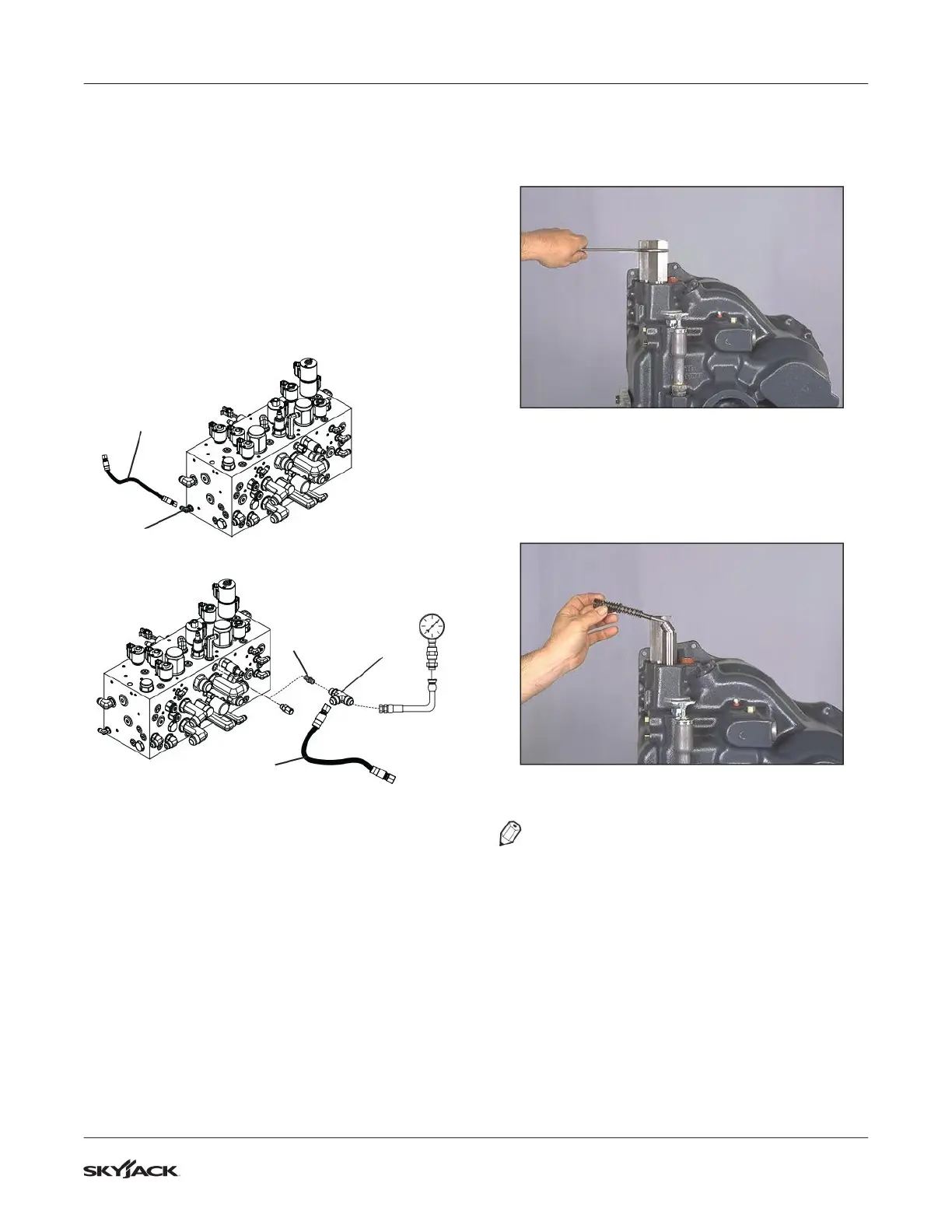

2. Remove inner, middle and outer springs, valve

stop pin and accumulator spool and regulator

spool and sleeve assembly as shown in figure

below.

Figure 113 Remove Modulator Valve Components

NOTE

Some units will have two cross pins the same

length. Some units will have two pins of different

lengths. The longest pin goes in the bottom hole.

Loading...

Loading...