20

Section 1 – Scheduled Maintenance General inspections

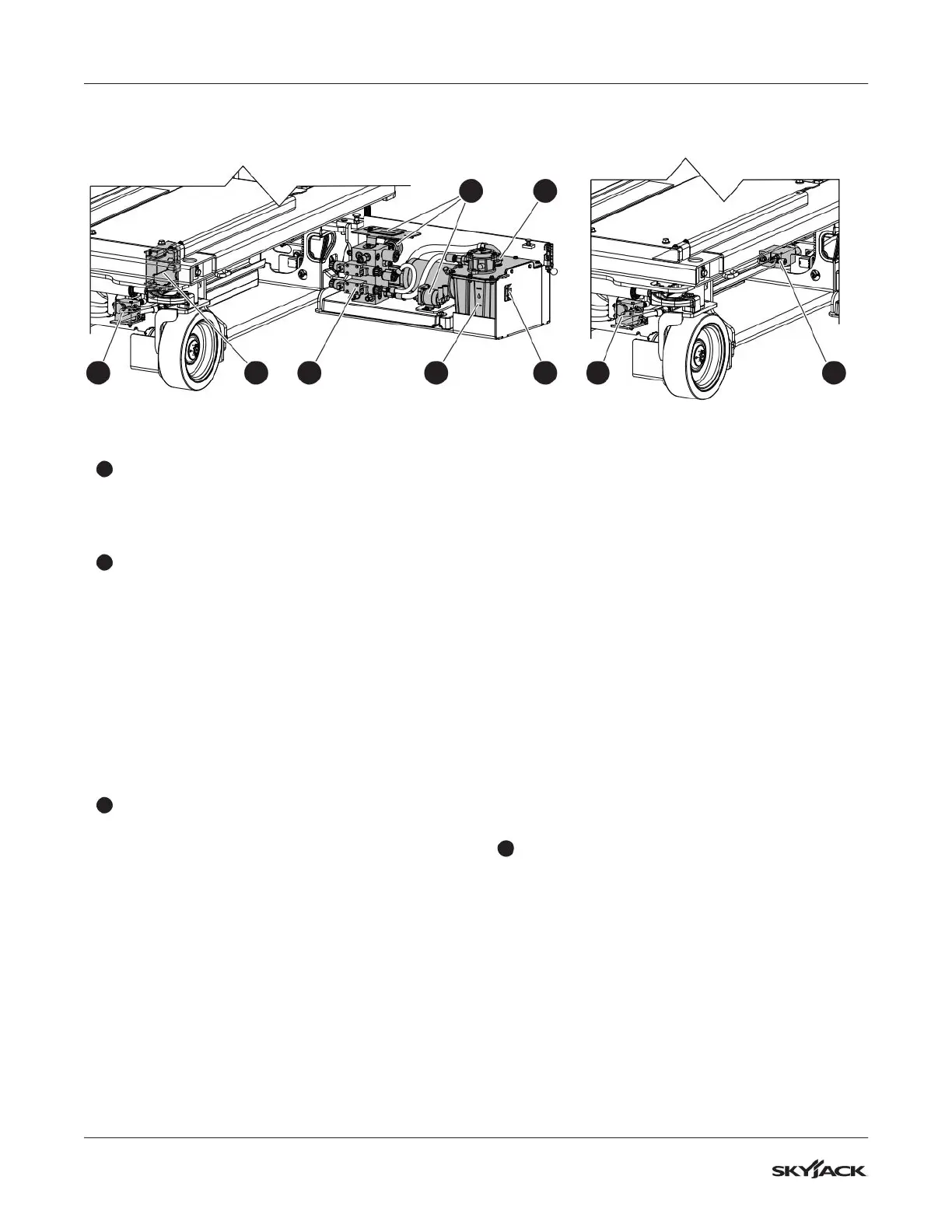

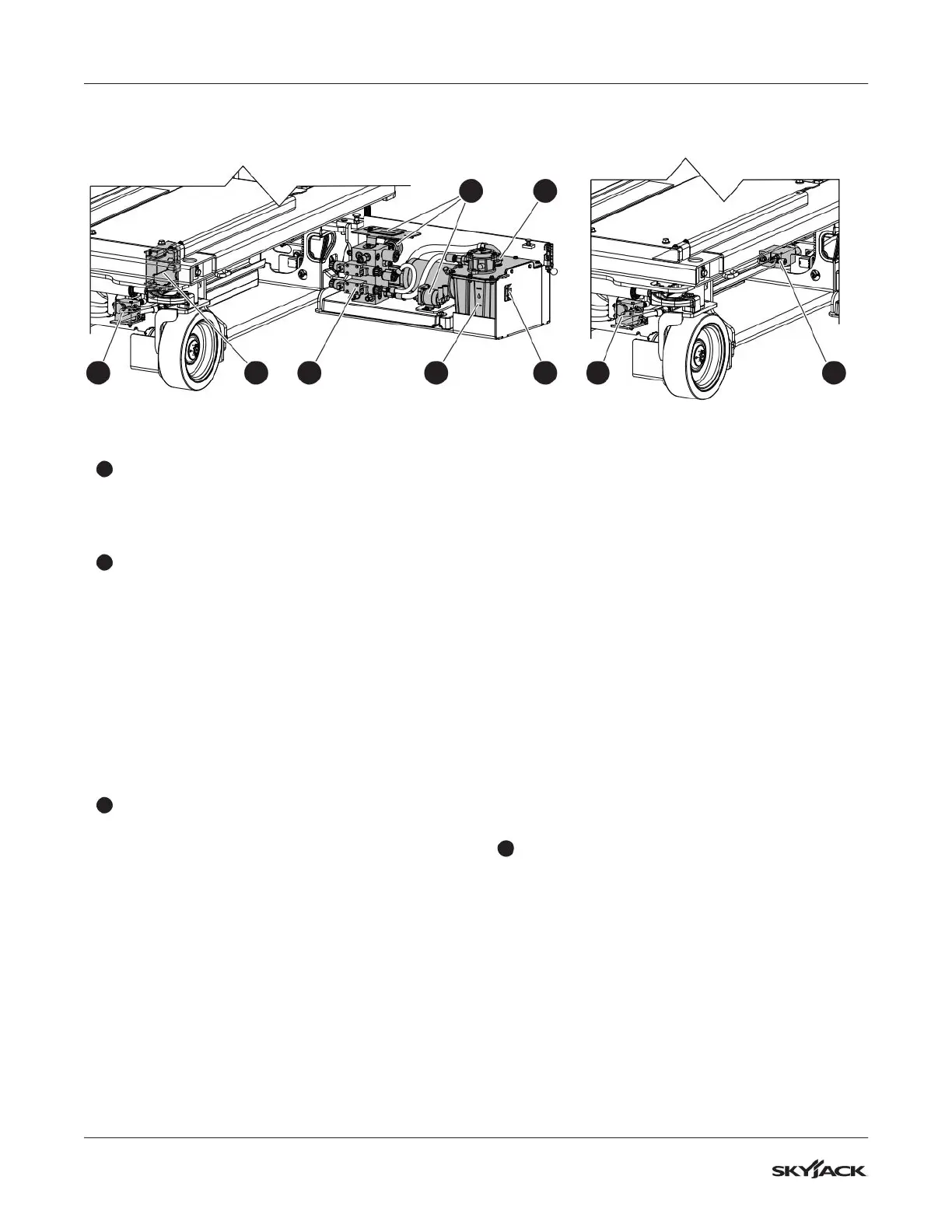

1

Hydraulic tank (B)

▪

Make sure the hydraulic filler cap closes tightly.

▪

Make sure there is no visible damage or hydraulic

leaks.

2

Hydraulic oil level (B, C)

▪

B - Frequent/periodic/pre-delivery inspection

▪

Fully lower the platform.

▪

Do a check on the gauge on the left side of the

hydraulic oil tank. The hydraulic oil level must

be at or a small distance above the top mark of

the gauge.

▪

C - Annual inspection

▪

Do a check of the hydraulic oil for contamination

and make sure the filter is in good condition.

▪

Replace the hydraulic oil and filters if necessary.

3

Electrical components (B)

▪

Do a check on these areas for chafed, corroded,

and loose wires:

1. Base to platform cables and wiring harness

2. Battery tray wiring harnesses

3. Hydraulic and electrical wiring harnesses.

▪

Skycoded™ display panel (B)

▪

Make sure the panel is correctly attached, and

there is no visible damage.

▪

Hydraulic pump and motor (B)

▪

Make sure there are no loose or missing

fasteners.

▪

Make sure there is no visible damage.

▪

Motor controller (B)

▪

Make sure the motor controller is correctly

attached, and there is no visible damage.

▪

Make sure there are no loose wires or missing

fasteners.

▪

Motor contactor (B)

▪

Make sure the motor contactor is correctly

attached, and there is no visible damage.

▪

Make sure there are no loose wires or missing

fasteners.

▪

Emergency lowering switch (B)

▪

Make sure the emergency lowering switch

is correctly attached, and there is no visible

damage.

▪

Make sure the toggle switch operates correctly.

▪

Make sure there are no loose wires or missing

fasteners.

4

Manifolds (B)

▪

Make sure all fittings and hoses are correctly

tightened.

▪

Make sure there is no indication of hydraulic

leakage.

▪

Make sure there are no loose wires or missing

fasteners.

▪

Make sure all the manual valves operate correctly

and do not seize.

34 4

Example model SJ3219 ANSI/CSA SJ3219 CE, AS & KC Manifolds

4 41

3

2

2

Loading...

Loading...