24

Section 1 – Scheduled Maintenance Scheduled Maintenance Inspections

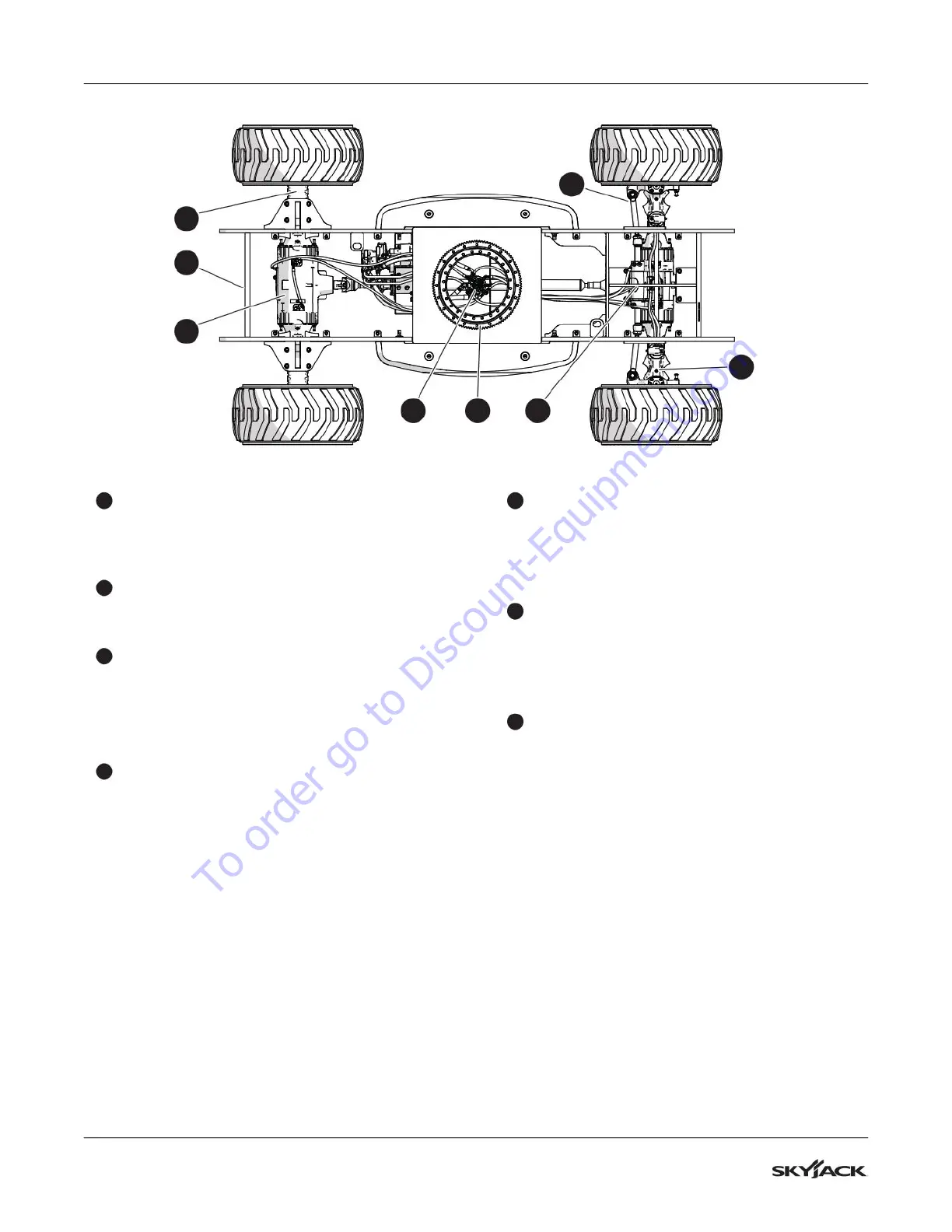

1

Base weldment (B)

▪

Make sure there are no visible cracks in

welds or structure and there are no signs of

deformation.

2

Rotary manifold (B)

▪

Make sure all hoses are correctly tightened

and there is no sign of hydraulic leakage.

3

Turret rotation gear (B,C)

▪

Make sure there are no loose or missing parts.

▪

Make sure there is no visible damage.

C - Annual Inspection

▪

For the lube procedure, refer

4

Axles (B,C)

▪

Make sure the front and rear axles are

correctly attached.

▪

Make sure there are no loose or missing parts.

▪

Make sure all the fittings and hose connections

are tight.

▪

Make sure there is no sign of hydraulic

leakage.

C - Annual Inspection

▪

Check the brakes annually. Refer to the

procedure 5.9-6 Brake Inspection.

5

Brakes (B)

▪

Make sure there are no loose or missing parts.

▪

Make sure all the fittings and hoses are

correctly tightened and there are no hydraulic

leaks.

6

Steer cylinder (B)

▪

Make sure there are no loose or missing parts.

▪

Make sure all the fittings and hoses are

correctly tightened and there are no hydraulic

leaks.

7

Steer linkage (B)

▪

Make sure there are no loose or missing parts.

▪

Make sure the tie rod end studs are locked

and there is no visible damage.

2

4

4

7

1

3 6

5

To order go to Discount-Equipment.com

Loading...

Loading...