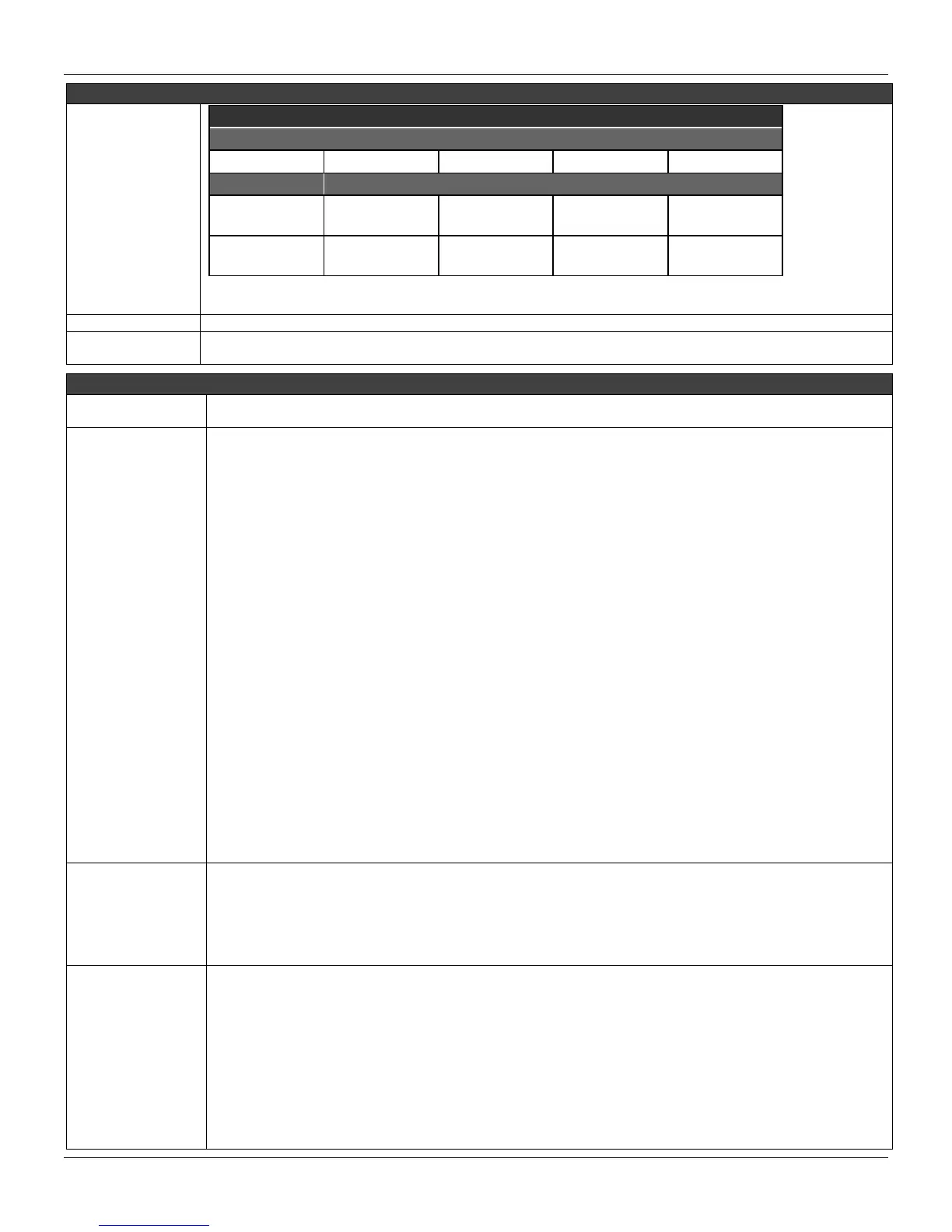

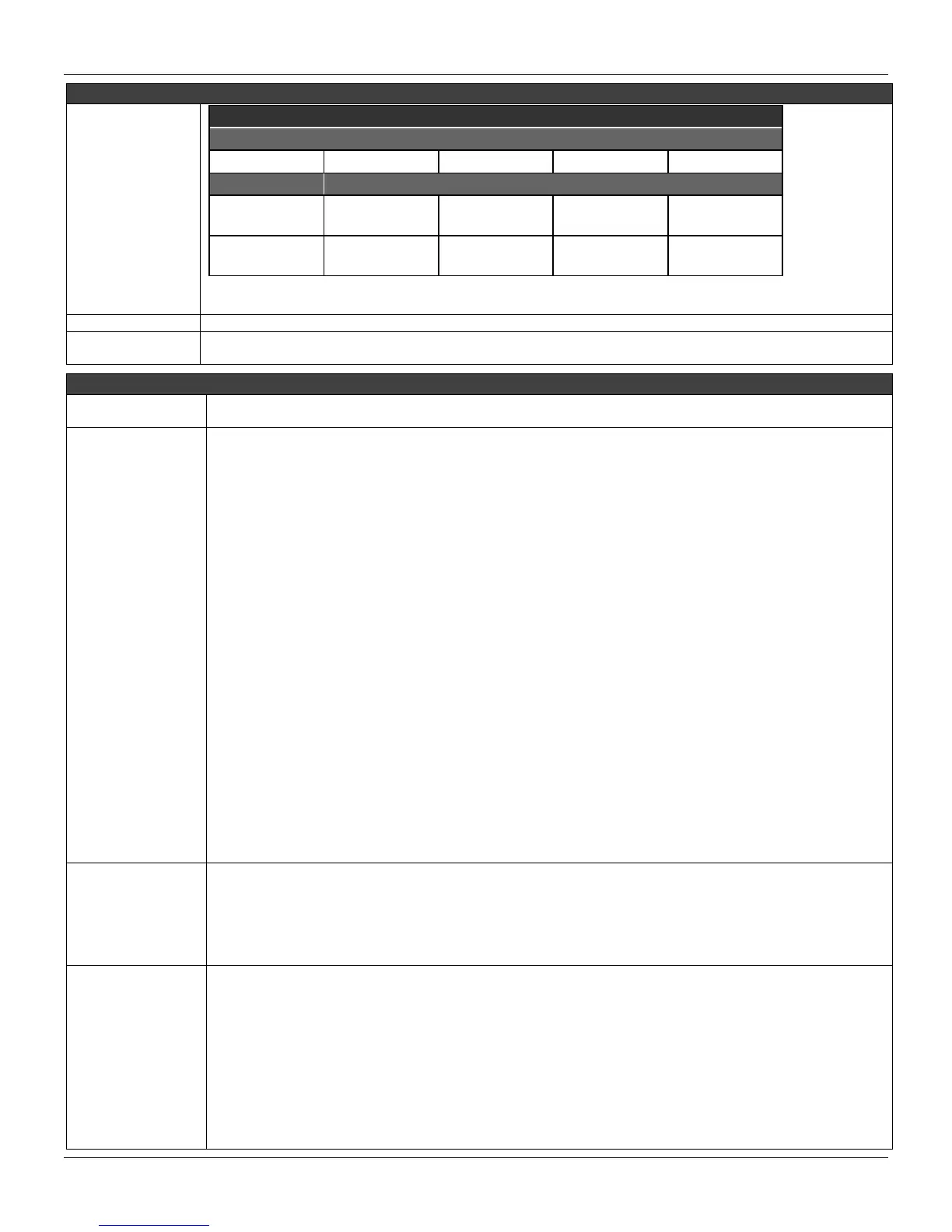

Technical Characteristics

6.3

Functional Specifications

DIN EN 1092-1 / DIN 2501

Flange Material: 316L Stainless Steel

Temperature - 10 a 50 °C 50 °C 100 °C 150 °C

PN Pressure Limit

16

1230 kPa

(178.4 psi)

1180 kPa

(171.1 psi)

1020 kPa

(148 psi)

930 kPa

(135 psi)

40

3060 kPa

(443.8 psi)

2960 kPa

(429.3 psi)

2550 kPa

(370 psi)

2310 kPa

(335 psi)

The overpressure above are not likely to damage the transmitter, although a new calibration may be needed.

Humidity Limits

0 to 100% RH (Relative Humid).

Damping

Adjustment

User configurable from 0 to 128 seconds (via digital communication).

Performance Specifications

Reference

Conditions

Span starting at zero, temperature of 25°C (77°F), atmospheric pressure, power supply of 24 Vcc, silicone

oil fill fluid, isolating diaphragms in 316L SST and digital trim equal to lower and upper range values.

Accuracy

For range 0, and differential or gage models and 316L SST or hastelloy diaphragm with silicon or

halocarbon filling fluid:

0.2 URL ≤ span ≤ URL: ± 0.1% of span

0.05 URL ≤ span < 0.2 URL: ± [0.025+0.015 URL/span]% of span

For ranges 1, 2, 3, 4, 5 or 6, differential or gage models, and 316L SST or hastelloy diaphragm with

silicon or halocarbon filling fluid:

0.1 URL ≤ span ≤ URL: ± 0.075% of span

0.025 URL ≤ span < 0.1 URL: ± [0.0375+0.00375.URL/span]% of span

0.0083 URL ≤ span < 0.025 URL: ± [0.0015+0.00465.URL/span]% of span

For ranges 2 to 6 and absolute model. For tantalum or monel diaphragm. For fluorolube filling fluid:

0.1 URL ≤ span ≤ URL: ± 0.1% of span

0.025 URL ≤ span < 0.1 URL: ± 0.05[1+0.1 URL/span]% of span

0.0083 URL ≤ span < 0.025 URL: ± [0.01+0.006 URL/span]% of span

For range 1 and absolute model:

± 0.2% of span

For ranges 2, 3 or 4 and level model and 316L SST diaphragm with silicon or halocarbon filling fluid

with maximum pressure matching the flange pressure class:

0.1 URL ≤ span ≤ URL: ± 0.075% of span

0.025 URL ≤ span < 0.1 URL: ± [0.0375+0.00375.URL/span]% of span

0.0083 URL ≤ span < 0.025 URL: ± [0.0015+0.00465.URL/span]% of span

Linearity effects, hysterese and repeatability are included.

Stability

For ranges 2, 3, 4, 5 and 6: ± 0.15% of URL for 5 years at 20 ºC temperature change and up to 7 MPa

(1000 psi) of static pressure.

For ranges 0 and 1: ± 0.2% of URL for 12 months at 20 ºC temperature change and up to 100 kPa (1bar)

of static pressure.

For Level model: ± 0.2% of URL for 12 months at 20 ºC temperature change.

Temperature

Effect

For ranges 2, 3, 4 and 5:

0.2 URL ≤ span ≤ URL: ± [0.02% URL + 0.06% span] per 20 ºC (68 ºF)

0.0085 URL ≤ span < 0.2 URL: ± [0.023% URL + 0.045% span] per 20 ºC (68ºF)

For range 1:

0.2 URL ≤ span ≤ URL: ± [0.08% URL + 0.05% span] per 20 ºC (68 ºF)

0.025 URL ≤ span < 0.2 URL: ± [0.06% URL + 0.15% span] per 20 ºC (68 ºF)

For range 0:

0.2 URL ≤ span ≤ URL: ± [0.15% URL + 0.05% span] per 20 ºC (68 ºF)

0.05 URL ≤ span < 0.2 URL: ± [0.1% URL + 0.3% span] per 20 ºC (68 ºF)

For level model:

Loading...

Loading...