28

02.11

Strapex SMA 20

1. Blow out sealing head, strap guides and fan with

compressed air.

2. Clean heating element with fi ne emergy cloth (do

not bend heating element).

First allow heating element to cool down.

3. Clean clamp, strap separator and slide plate (see

Chapter 7.2).

4. Replace tension belt (see Chapter 7.5).

Protect tensioning belt from lubricants! Do

not use any oil! The use of oil can lead to

„mushy“ contamination in the presence of fi ne strap

dust particles, which cause blockage of moving parts.

Task Interval

Weekly Monthly after approx.

100000 strappings

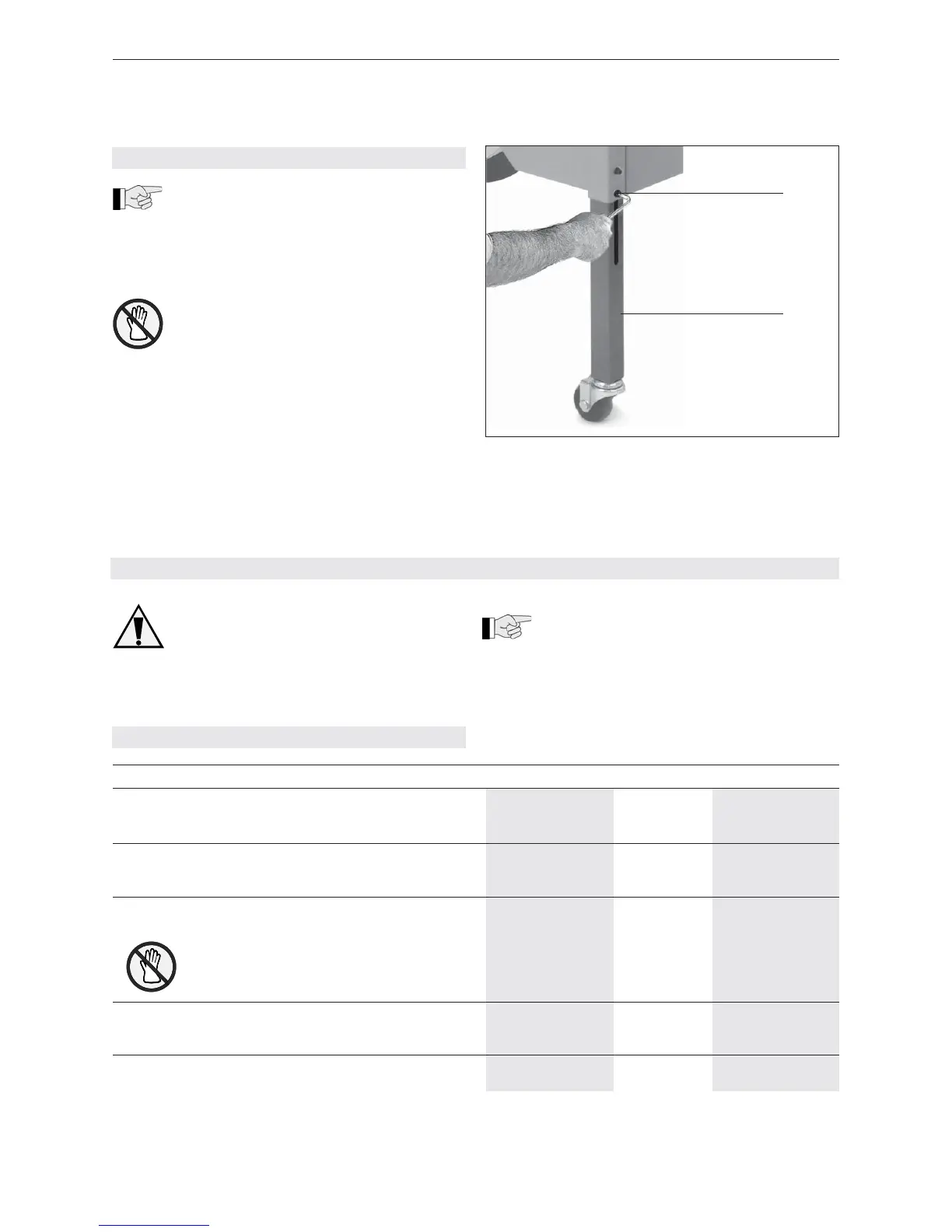

Fig. 10

1 Cylinder screw

2 Leg

6.8 ADJUST MACHINE HEIGHT

The table height is adjustable from 700 to

830 mm.

– Hold machine and loosen two cylinder screws

(10/1) on one of the legs (10/2).

– Adjust leg to required height and tighten up cylinder

screws again.

Never loosen two legs at the same time (risk

of tipping over)!

– Adjust the other legs to the same height.

– Lock both locking wheels before strapping.

7 PREVENTIVE MAINTENANCE

For preventive maintenance, disconnect the

power plug!

The machine requires little maintenance. All bearings

are permanently lubricated.

7.1 PREVENTIVE MAINTENANCE SCHEDULE

•

•

•

•

1

2

Loading...

Loading...