30

02.11

Strapex SMA 20

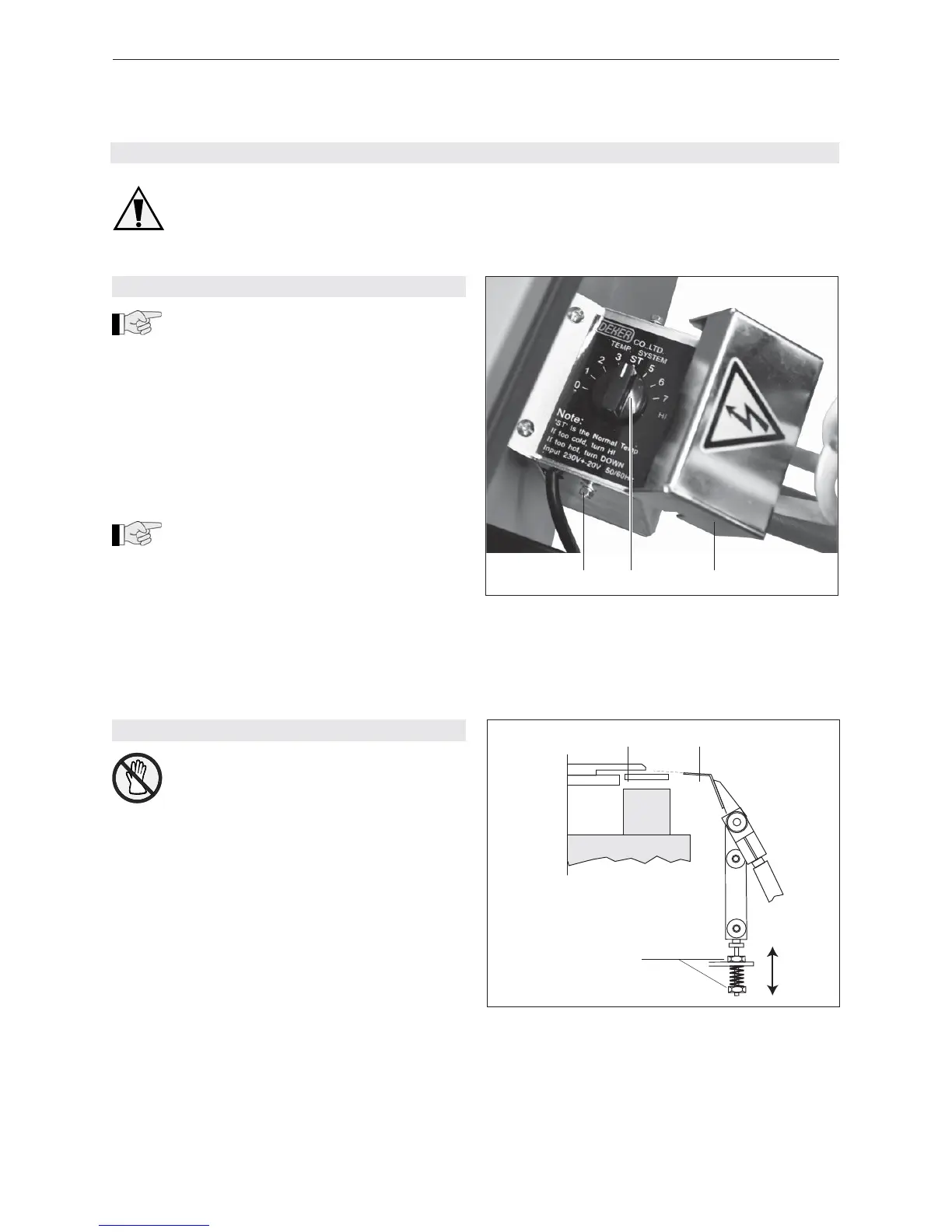

Fig. 12

1 Hexagonal head parker screw

2 Potentiometer

3 Cover

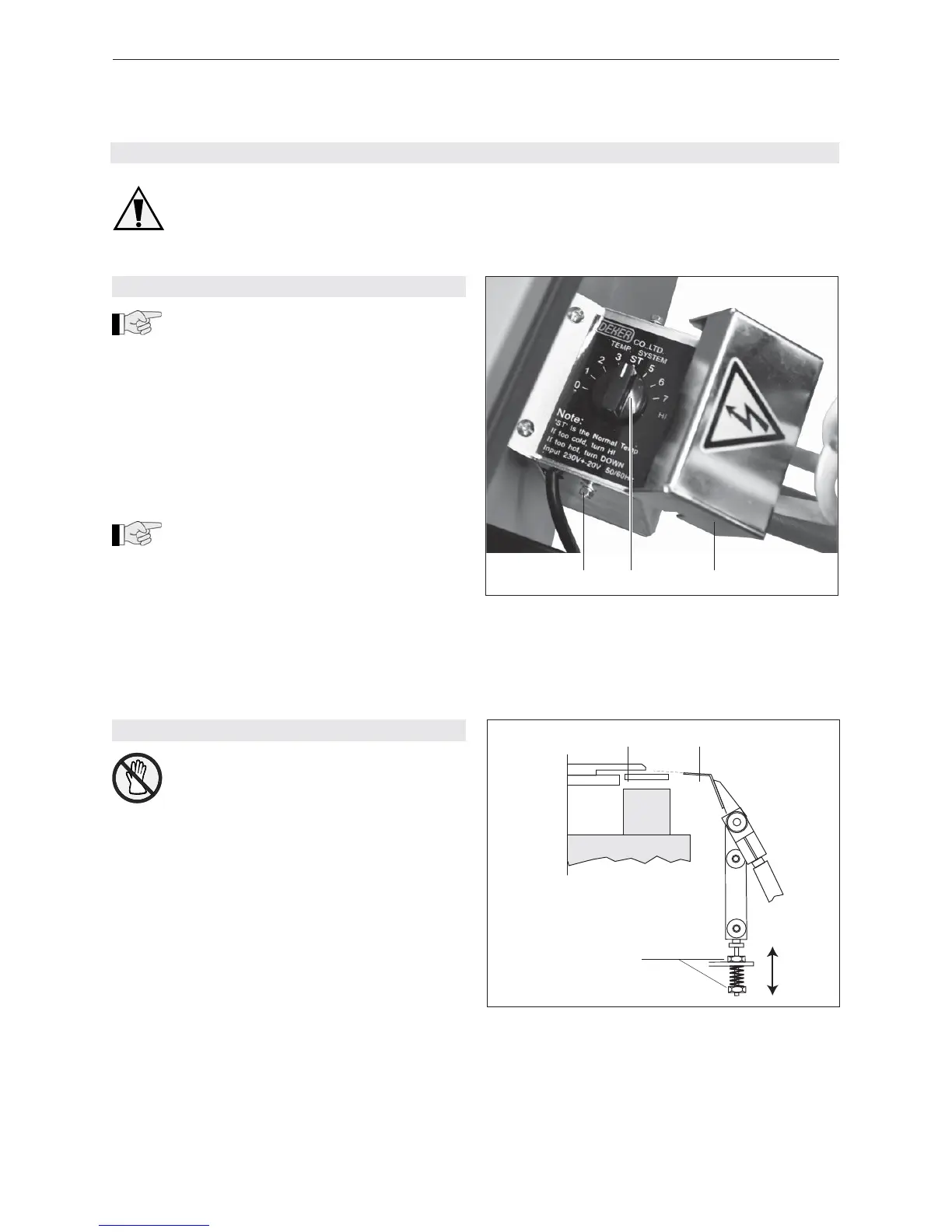

Fig. 13

1 Strap separator

2 Heating element

3 Nuts

8 CORRECTIVE MAINTENANCE

Disconnect the machine from the mains

supply before undertaking any maintenance

work.

8.1 ADJUST WELDING TEMPERATURE

The welding temperature can be adjusted to

suit the strap thickness and strap quality:

– For narrow, thin straps = low temperature.

– For wide, thick straps = high temperature.

– Open table top.

– Loosen two hexagonal head parker screws (12/1)

and remove cover (12/3).

– Set potentiometer (12/2) to desired temperature.

– ST = Default (factory setting)

– Pos. 0 = lowest temperature, approx. 220°C

– Pos. 7 = highest temperature, approx. 325°C

The warming-up time for the heating element

is about 45 seconds.

– Mount the cover (12/3) and fi x it with the hexagonal

head parker screws (12/1), close table top.

3

12

8.2 ADJUST HEIGHT OF HEATING ELEMENT

First of all let the heating element cool down.

– Open table top

– With a long hexagon-socket screw wrench (placed

through hole in side wall) turn coupling in direction

of arrow, until the heating element has reached the

position shown in Fig. 13.

– With the nuts (13/3) set the heating element (13/2)

in such a way that the upper side of the heating

element is a little (approx. 0.2 mm) over the top of

the strap separator (13/1).

1 2 3

Loading...

Loading...