Cross Switch It is to control the elevating and revolution . there are four sign on it.

When switched to “SPDL.FOR.”,the spindle revolves clockwise,

When switched to “SPDL.REV.”,it revolves counter clockwise,

When switched to “Arm UP”, the Arm lifts, When switched to

“Arm Down” , the arm descends.

8.

Work light switch It is used to improve lighting where illumination is not enough.

Ⅱ

ⅡⅡ

Ⅱ.For TPR-1100 (Type II)

Description for Switches.

For TPR-1100 (Type II)

1.

It is for operator’s understanding whether the working situation is

normal.

2.

Feeding light

It lights when at feeding. After work finished and power off, it turns

off .

3.

The cutting fluids

switch

It is a switch to start on or off the lubrication when at boring, where

the boring or shearing causes high temperature, making the drilling

bit easy to wear. The lubrication can reduce the temperature and

l

engthen the life of the drilling bit. Turn on to start and off to stop the

lubrication. The floating capacity is decided by another knob called

the cutting fluids adjusting knob.

4.

Emergent stop It is pressed to stop the machine when at processing and emergence

occurs. Pull it again for back to release the stop.

5.

When the external power and the main machine power switch are on,

the power light will be on, indicating to the operator that the power is

Pole change switch

The spindle motor is a pole variable one. A regular motor has 4 pole.

But this one is changeable between 4 and 8 pole. It can change the

spindle rotating speed.

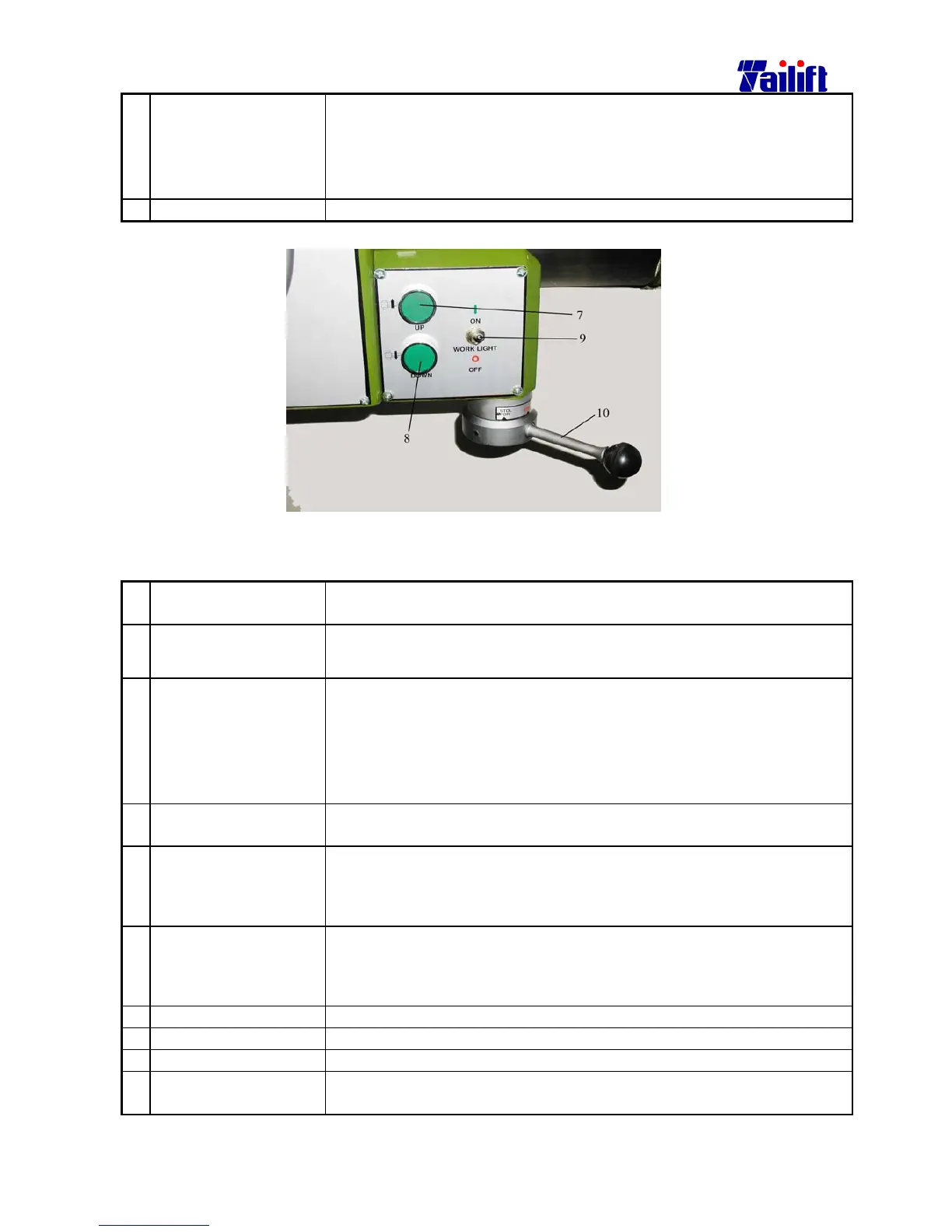

7.

Arm uplift switch The arm will uplift when pushing the “up”button.

8.

Arm downlift switch The arm will be lowered down when pushing the “down” button.

9.

To lighten the working area.

10.

-reverse switch

When switch to SPDL.FOR, The spindle will forward . When switch

To SPDL.REV.the spindle will reverse.

Loading...

Loading...