L-

-R

DRUMS-PLAIN

(SMOOTH)

Installation

of

a wire rope on a plain (smooth) face drum requires a great deal

of

care.

The

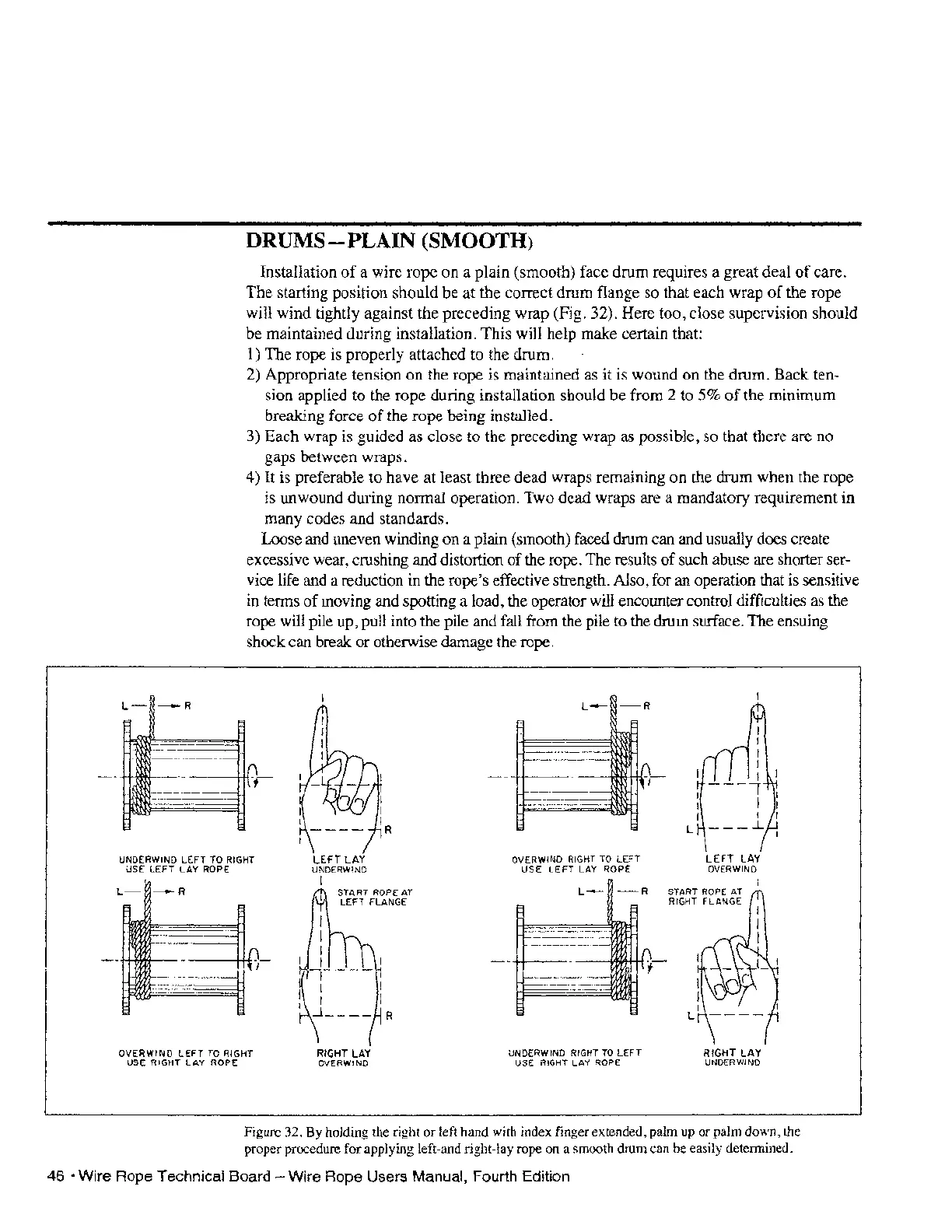

starting position should be at the correct drum flange so that each wrap

of

the rope

will wind tightly against the preceding wrap (Fig. 32). Here too, close supervision should

be

maintained during installation. This will help make certain that:

1)

The

rope

is

properly attached to the drum.

2) Appropriate tension

on

the rope is maintained as it is wound on the drum. Back ten-

sion applied to the rope during installation should be from 2 to 5%

of

the minimum

breaking force

of

the rope being installed.

3) Each wrap is guided as close to the preceding wrap as possible, so that there are no

gaps between wraps.

4) It is preferable to have at least three dead wraps remaining on the drum when the rope

is unwound during normal operation. Two dead wraps are a mandatory requirement in

many codes and standards.

Loose and uneven winding

on

a plain (smooth) faced drum can and usually does create

excessive wear, crushing and distortion

of

the rope. The results

of

such abuse are shorter ser-

vice life and a reduction in the rope's effective strength. Also, for an operation that

is

sensitive

in terms

of

moving and spotting a load, the operator will encounter control difficulties as the

rope will pile up, pull into the pile and fall from the pile to the drum surface. The ensuing

shock can break or otherwise damage the rope.

L--

-R

-

f,.

UNDERWIND

LEFT

TO

RIGHT

USE

LEFT

LAY

ROPE

LEFT

LAY

UNDERWIND

I

OVERWIND

RIGHT

TO

LEFT

USE

LEFT

LAY ROPE

LEFT

LAY

OVERWIND

L-

-R

----t+:i:.[L

_~~~"I

OVERWIND

LEFT

TO

RIGHT

USE RIGHT

LAY

ROPE

START

ROPE

AT

LEFT

FLANGE

RIGHT

LAY

OVERWIND

L--~

-R

UNDERWIND

RIGHT

TO

LEFT

USE

RIGHT

LAY

ROPE

t

RIGHT

LAY

UNDERWIND

Figure 32. By holding the right or left hand with index finger extended, palm up or palm down, the

proper procedure for applying left-and right-lay rope on a smooth drum can

be easily determined.

46·

Wire Rope Technical Board - Wire Rope Users Manual, Fourth Edition

Loading...

Loading...