CROSS

OVER

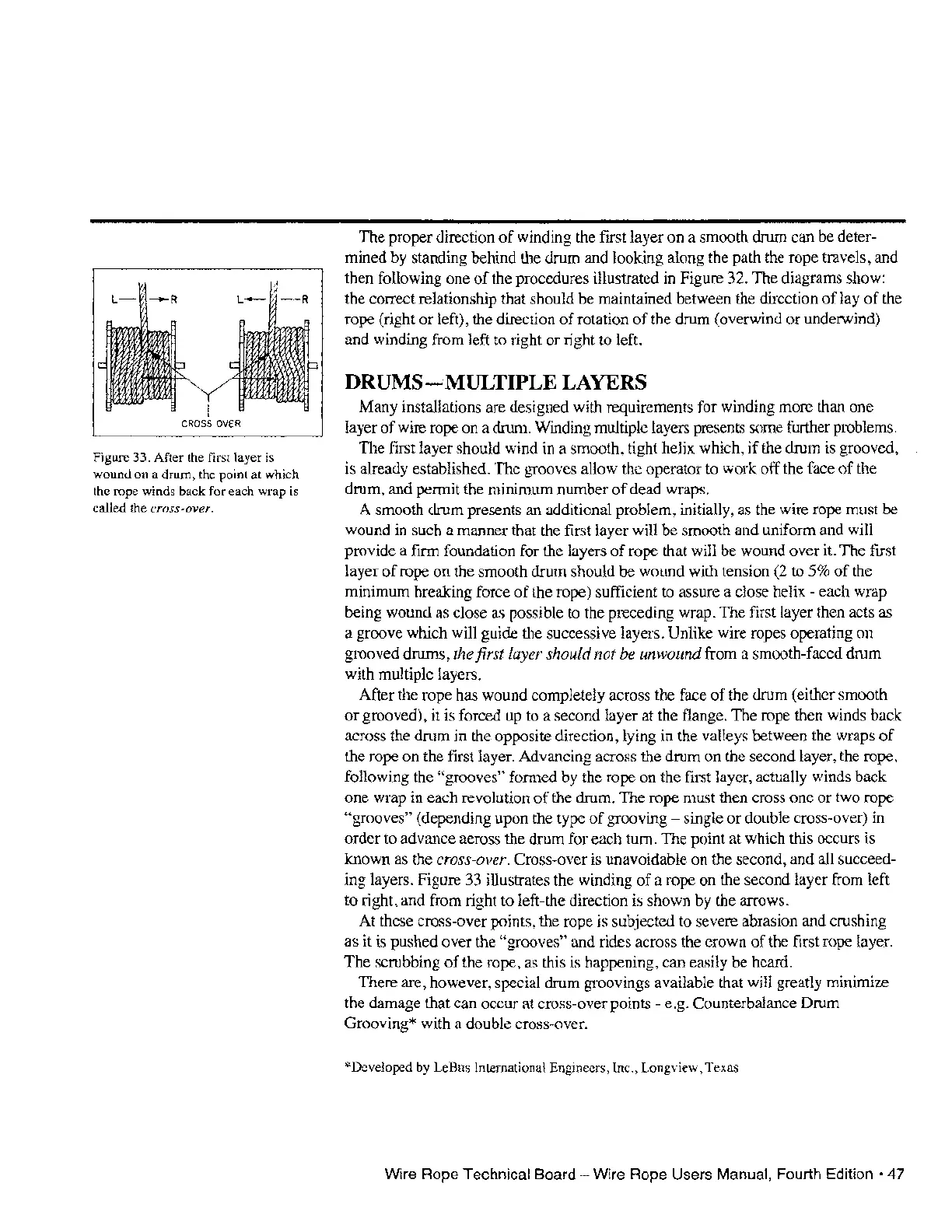

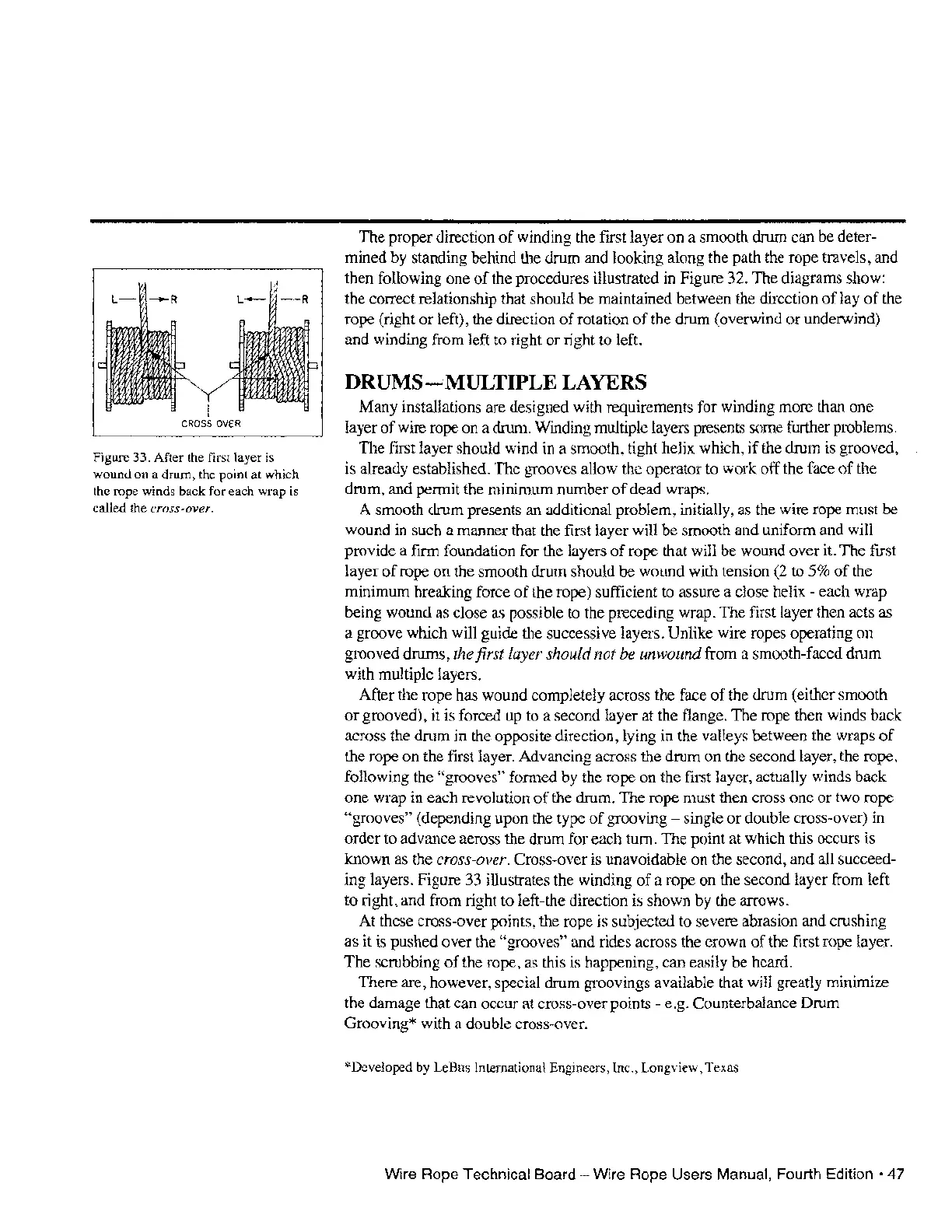

Figure 33. After the first layer is

wound on a drum, the point at which

the rope winds back for each wrap is

called the

cross-over.

The proper direction

of

winding the first layer

on

a smooth drum can be deter-

mined by standing behind the drum and looking along the path the rope travels, and

then following one

of

the procedures illustrated in Figure 32. The diagrams show:

the correct relationship that should

be

maintained between the direction

of

lay

of

the

rope (right

or

left), the direction

of

rotation

of

the drum (overwind

or

underwind)

and winding from left to right

or

right to left.

DRUMS.....;MULTIPLE

LAYERS

Many installations are designed with requirements for winding more than one

layer

of

wire rope on a drum. Winding multiple layers presents some further problems.

The first layer should wind

in

a smooth, tight helix which,

if

the drum

is

grooved,

is already established.

The

grooves allow the operator to work

off

the face

of

the

drum, and permit the minimum number

of

dead wraps.

A smooth drum presents an additional problem, initially, as the wire rope must be

wound in such a manner that the first layer will

be

smooth and uniform and will

provide a firm foundation for the layers

of

rope that will be wound over it. The first

layer

of

rope

on

the smooth

drum

should

be

wound with tension (2 to 5%

of

the

minimum breaking force

of

the rope) sufficient to assure a close helix - each wrap

being wound as close as possible to the preceding wrap. The first layer then acts as

a groove which will guide the successive layers.

Unlike wire ropes operating on

grooved drums,

the first layer should not be unwound from a smooth-faced drum

with multiple layers.

After the rope has wound completely across the face

of

the drum (either smooth

or

grooved),

it

is forced up to a second layer at the flange. The rope then winds back

across the drum in the opposite direction, lying in the valleys between the wraps

of

the rope

on

the first layer. Advancing across the drum on the second layer, the rope,

following the

"grooves" formed by the rope on the first layer, actually winds back

one wrap in each revolution

of

the drum. The rope must then cross one

or

two rope

"grooves" (depending upon the type

of

grooving - single

or

double cross-over) in

order to advance across the drum for each turn.

The

point at which this occurs is

known as the

cross-over. Cross-over is unavoidable on the second, and all succeed-

ing layers. Figure 33 illustrates the winding

of

a rope

on

the second layer from left

to right, and from right to left-the direction is shown by the arrows.

At these cross-over points, the rope is subjected to severe abrasion and crushing

as

it

is pushed over the "grooves" and rides across the crown

of

the first rope layer.

The scrubbing

of

the rope, as this is happening, can easily

be

heard.

There are, however, special drum groovings available that will greatly minimize

the damage that can occur at cross-over points

- e.g. Counterbalance Drum

Grooving* with a double cross-over.

"Developed by LeBus International Engineers, Inc., Longview, Texas

Wire Rope Technical Board - Wire Rope Users Manual, Fourth

Edition'

47

Loading...

Loading...