The wrong cable wedge could permit the wire rope to

work lose and detach itself from the drum; possibly

causing property damage or personal injury.

Tension the wire rope by braking the shipping reel and

slowly operate the winch in the raise mode to wind the

cable onto the winch drum. As the spooling proceeds,

make sure the adjacent turns are tight against one an-

other. A lead or brass hammer may be used to tap the

rope over against preceding turns. Tight winding on the

drum is absolutely essential.

Never use a steel hammer or pry bar to move the rope

over on the drum. These tools can easily damage the

rope.

After the rope is wound onto the winch drum, reeve the

cable as desired.

Use only factory supplied sockets, wedges and pins of

the proper size; make no substitutions.

Follow the procedure below when installing wedge

type sockets on wire rope. Be certain the correct sock-

et and wedge are used.

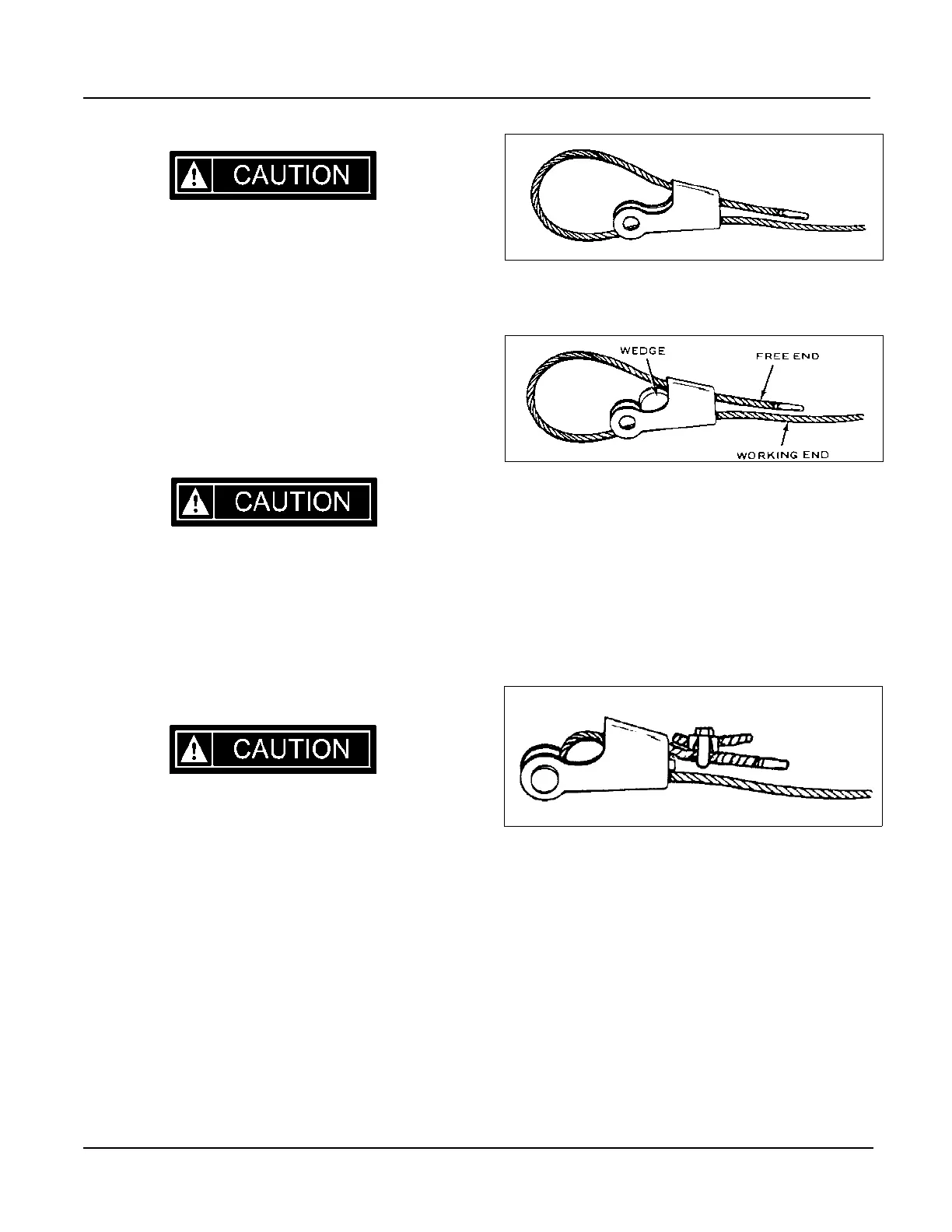

1. Lead the rope through the socket, form a large loop

and draw the rope end back through the socket. A

length of rope equal to at least one rope lay should

be drawn back through.

MAINTENANCE AND LUBRICATION

2. Insert the wedge and allow the rope strands to adjust

around it.

3. Seat the wedge and loop just tightly enough to allow

handling by attaching the socket to a strong support

and engaging the winch to take a strain on the rope.

4. Final seating of the wedge is accomplished by mak-

ing lifts of gradually increasing loads. avoid imposing

shock loads on the rope until the wedge is firmly in

place.

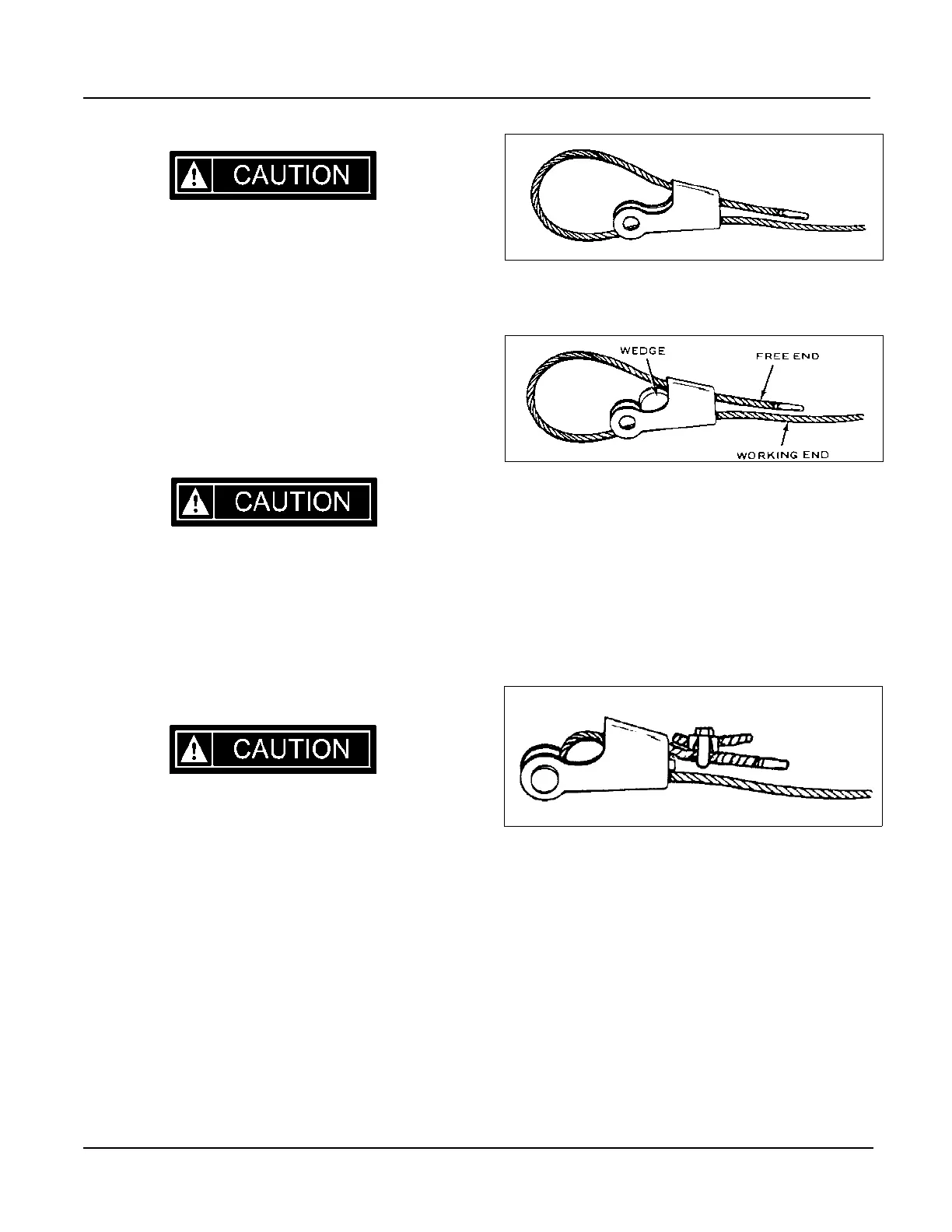

5. After the wedge has been firmly seated, a short

length (6 inches) of the cable should be secured to

the free end of the wire rope to act as a stop as

shown. DO NOT clamp the free end to the load sup-

porting end as this will weaken the rope.

4 - 34 Revised: March 2005RT700 Series

Loading...

Loading...