Drive Shaft Maintenance

Rotating shafts can be dangerous. You can snag clothes, skin, hair, hands, etc.

This can cause serious injury or death. Do not work on a shaft (with or without a

guard) when the engine is running.

UNIVERSAL JOINTS

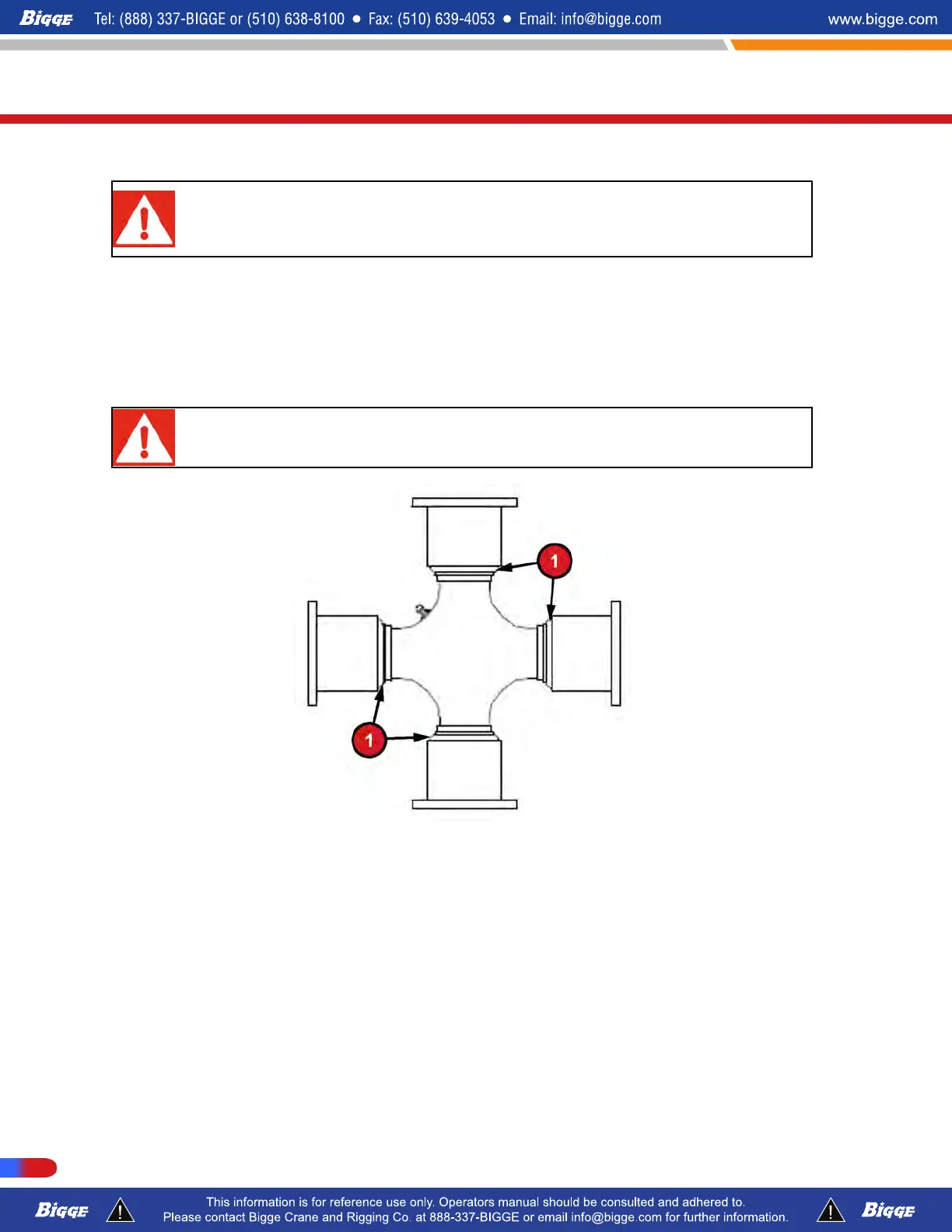

To insure proper lubrication of the bearing assemblies, it is essential to add lubricant until it

appears at all journal cross bearing seals (1). This assures removal of dirt particles and

other contaminants that may find their way into the bearings and indicates to the mechanic

that the bearings are fully lubricated.

Do not assume that bearing cavities have been filled with new lubricant unless

flow is noticed around all four bearing seals! (1).

If all the seals do not “pop” when being lubed, move the drive shaft laterally in all four

directions and pull or push on the drive shaft in the direction opposite to the journal cross

seal not relieving while lube gun pressure is being applied to the alemite fitting.

It is recommended that all universal joints be relubed after installation of the drive

shaft prior to putting a vehicle in service.

JOURNAL AND BEARING KITS

It is necessary to completely lubricate each replacement kit prior to assembly into the drive

shaft yokes. Each journal cross lube reservoir should be fully packed with a recommended

grease and each bearing assembly should also be wiped with the same grease; filling all

the cavities between the rollers and applying a liberal grease coating on the bottom of each

race. After the kits are installed into the drive shaft yokes and prior to placing into service,

they should be relubed, through the zerks, using the same grease.

T300-1_T500-1_T780

Maintenance

312 P/N 12261-683

REVISED: January 2015

Loading...

Loading...