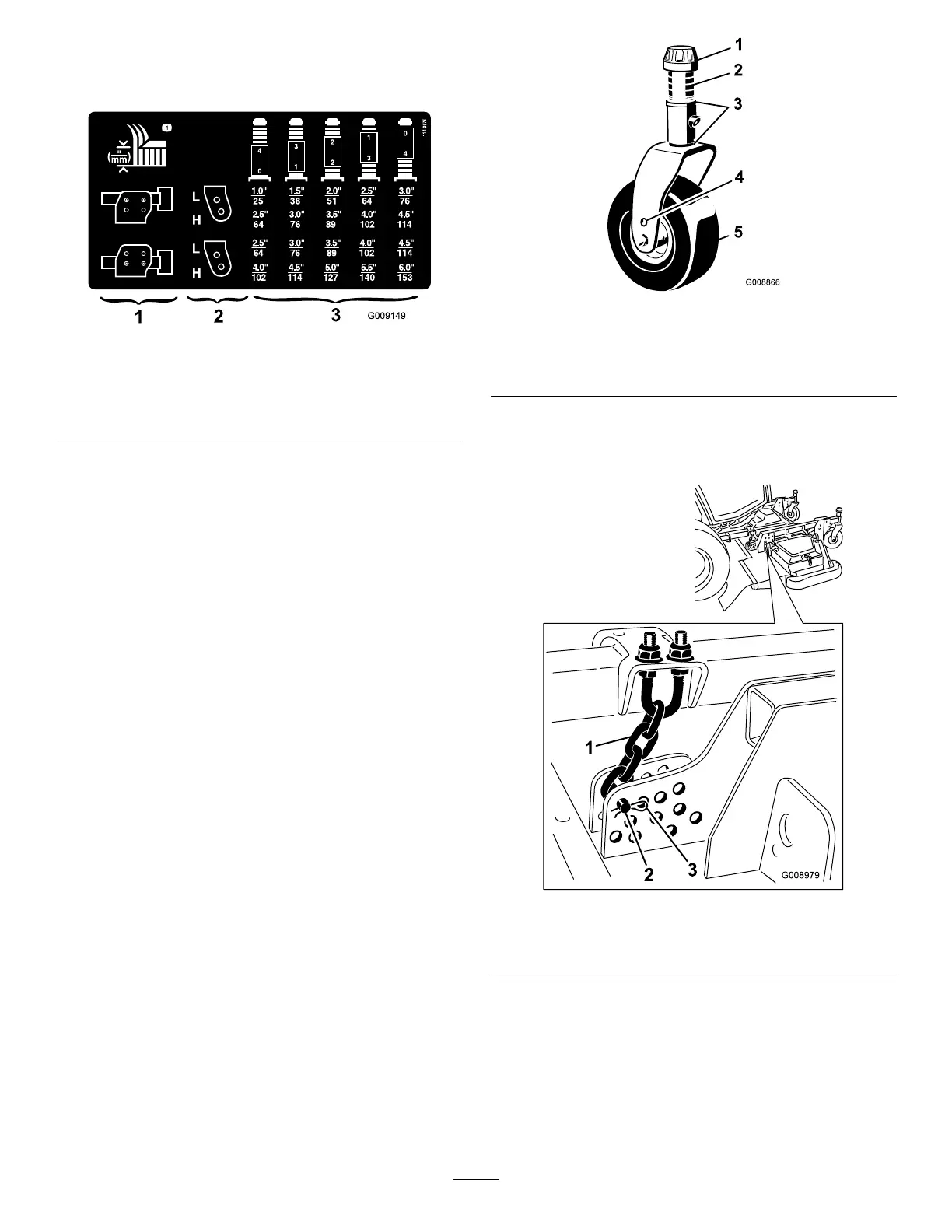

2.Positionthecastorwheelaxlesinthesameholesin

allcastorforks.Refertothechart(Figure22)to

determinethecorrectholesforthesetting.

Figure22

1.Castorarmheightofcut

mountingholes

3.Castorforkheightofcut

spacers

2.Castorforkheightofcut

mountingholes

Note:Whenoperatingat2-1/2inch(64mm)

heightofcutorhigher,theaxleboltshouldbe

installedinthebottomcastorforkholetoprevent

grassbuildupbetweenthewheelandthefork.

Whenoperatingatheightsofcutlowerthan2-1/2

inches(64mm)andgrassbuildupisdetected,

reversethemachinesdirectiontopullanyclippings

awayfromthewheel/forkarea.

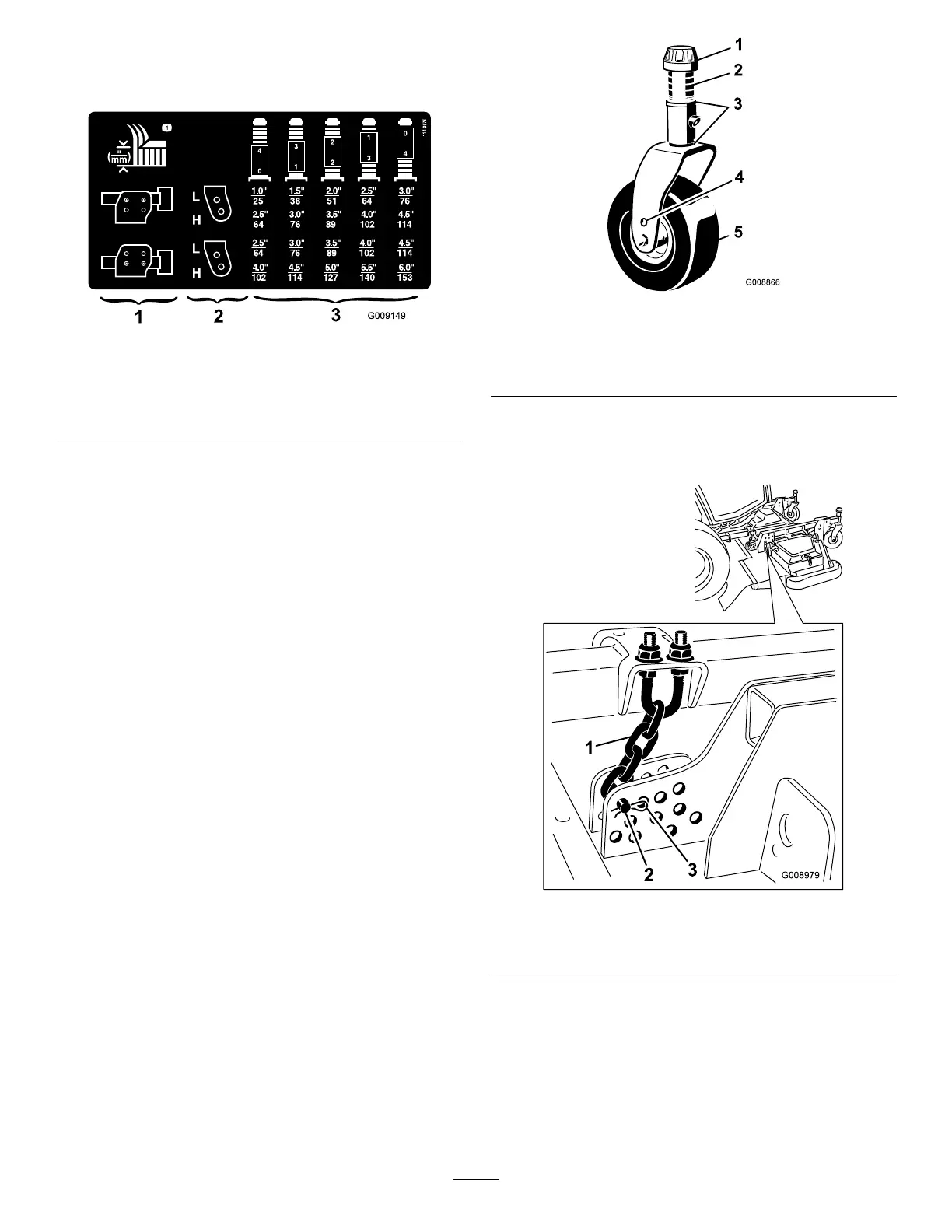

3.Removethetensioningcapfromthecastorshaft

(

Figure23).andslidetheshaftoutofthecastor

arm.Put2shims(1/8inch[3mm])ontothecastor

shaftasoriginallyinstalled.Slidetheappropriate

numberof1/2inchspacersontotheshafttoget

thedesiredheight-of-cut.

Note:Theshimwashersmaybeusedinany

combinationaboveorbelowthecastorarmhub

asrequiredtoachievethedesiredheightofcutor

decklevel.

Refertothechart(

Figure22)todeterminethe

combinationsofspacersforthesetting:

4.Pushthecastorshaftthroughthefrontcastor

arm.Installtheshims(asoriginallyinstalled)and

theremainingspacersontotheshaft.Installthe

tensioningcaptosecuretheassembly(Figure23).

Figure23

1.Tensioningcap4.Topaxlemountinghole

2.Spacers(4)5.Castorwheel

3.Shims(2top&2bottom

5.Removethehairpincotterandclevispinsecuring

theheight-of-cutchainstotherearofthecutting

unit(Figure24).

Figure24

1.Height-of-cutchain

3.Hairpincotter

2.Clevispin

30

Loading...

Loading...