6.Mounttheheight-of-cutchainstothedesired

height-of-cuthole(Figure25)withtheclevispin

andhairpincotter.

Figure25

Note:Whenmowingatheight-of-cutsbelow

2–1/2inches(51mm),movetheskids,gagewheels

androllerstothehighestholes.

7.Toattainthe5to6inch(102to153mm)heightof

cutsettings,removethemountingboltssecuring

thedeckhangerbracketstotheheightofcutcastor

armsandremountthedeckhangerbracketstothe

heightofcutcastorarmsusingthelowersetof

holes(

Figure26).

Figure26

1.Lowermountingbolts

SideCuttingUnits

1.Starttheengineandraisethecuttingunitssothat

theheight-of-cutcanbechanged.Stoptheengine

andremovethekeyafterthecuttingunitisraised.

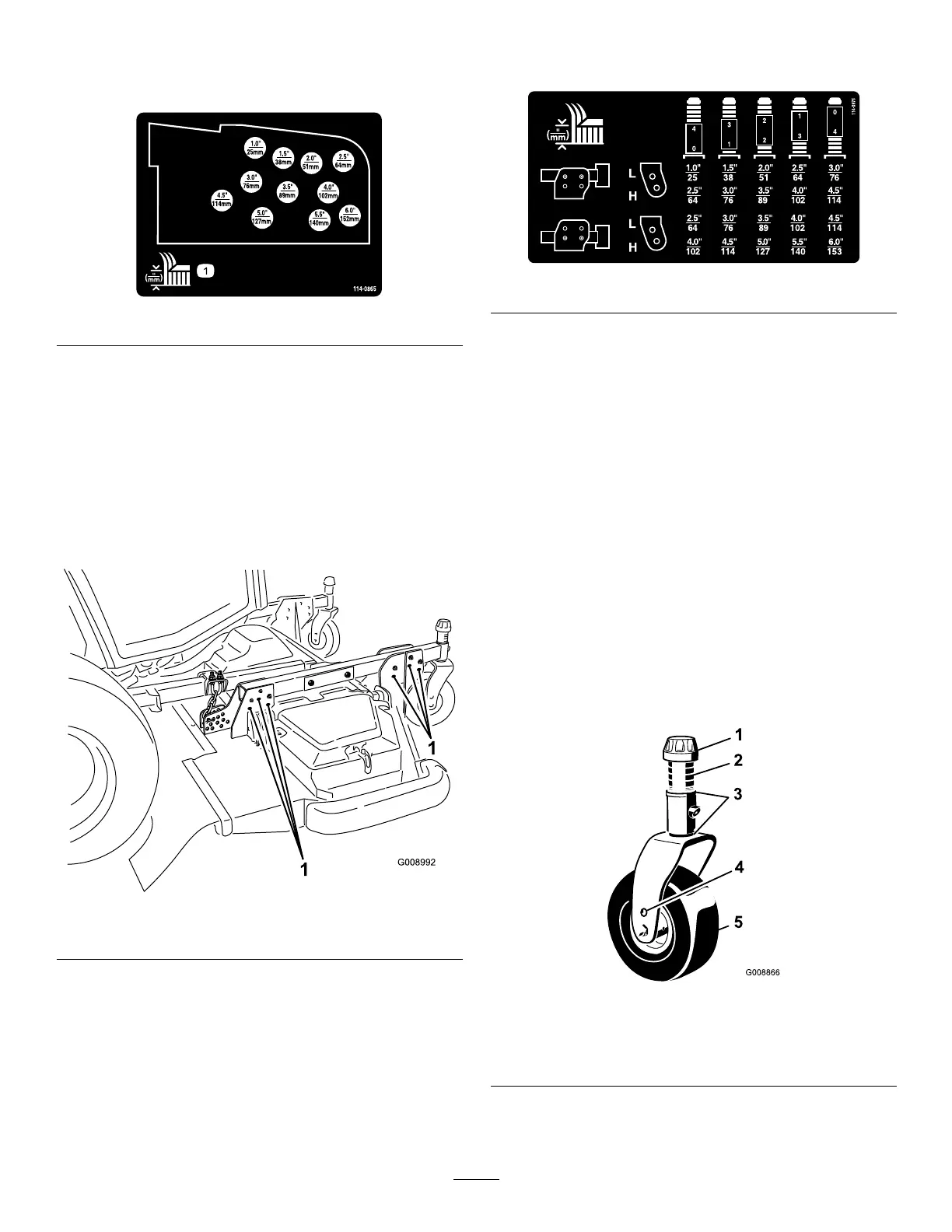

2.Positionthecastorwheelaxlesinthesameholes

inallcastorforks.Refertothechart(Figure27)

todeterminethecorrectholesfortheheightof

cutsetting.

Figure27

Note:Whenoperatingat2-1/2inch(64mm)

heightofcutorhigher,theaxleboltshouldbe

installedinthebottomcastorforkholetoprevent

grassbuildupbetweenthewheelandthefork.

Whenoperatingatheightsofcutlowerthan2-1/2

inches(64mm)andgrassbuildupisdetected,

reversethemachinesdirectiontopullanyclippings

awayfromthewheel/forkarea.

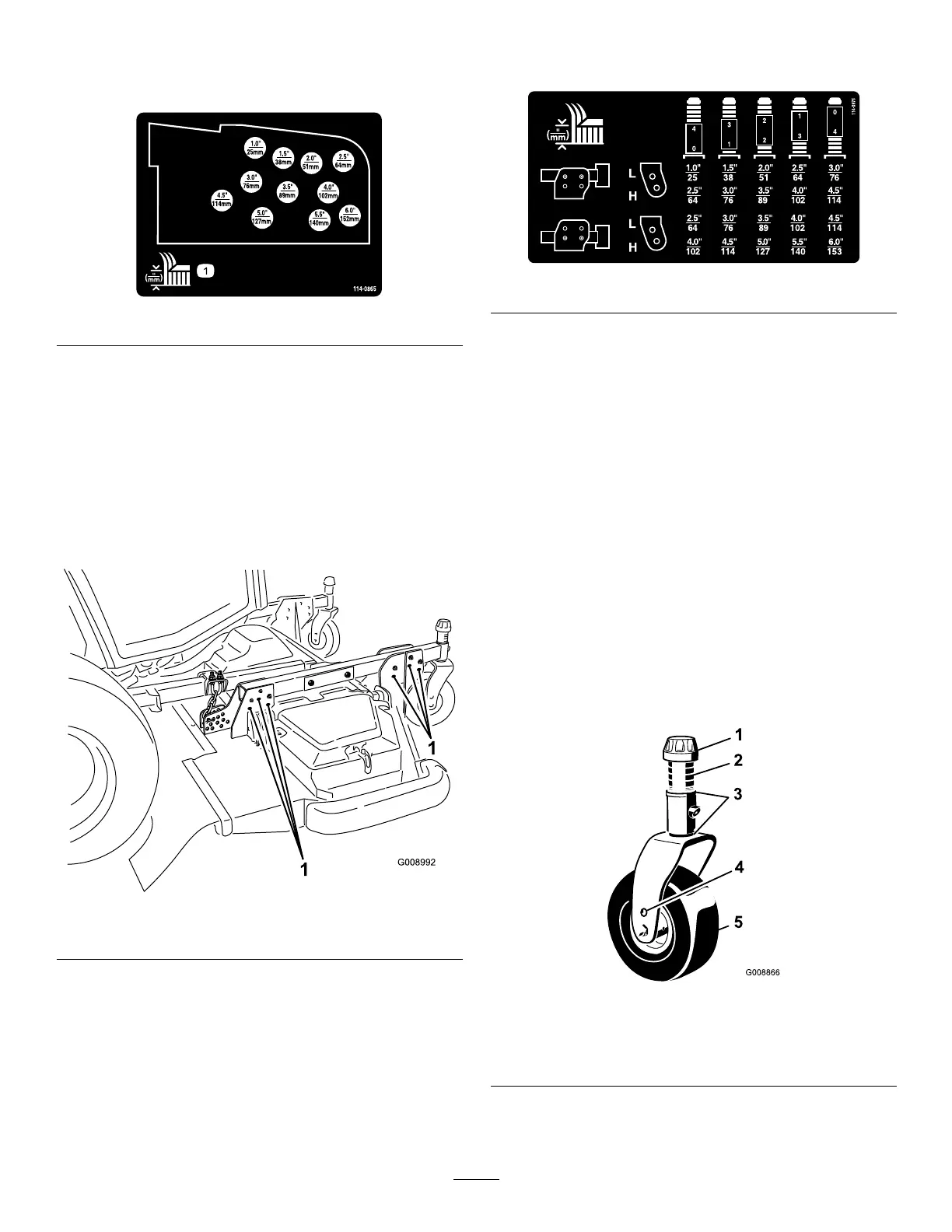

3.Removethetensioningcapfromthecastorspindle

shaft(

Figure28)andslidethecastorshaftoutof

thecastorarm.Put2shims(1/8inch[3mm])onto

theshaftasoriginallyinstalled.Slidetheappropriate

numberof1/2inchspacersontotheshafttoget

thedesiredheight-of-cut.

Note:Theshimwashersmaybeusedinany

combinationaboveorbelowthecastorarmhub

asrequiredtoachievethedesiredheightofcutor

decklevel.

Figure28

1.Tensioningcap4.Topaxlemountinghole

2.Spacers(4)5.Castorwheel

3.Shims(2topand2bottom)

4.Pushthecastorshaftthroughthecastorarm.Install

theshims(asoriginallyinstalled)andtheremaining

31

Loading...

Loading...