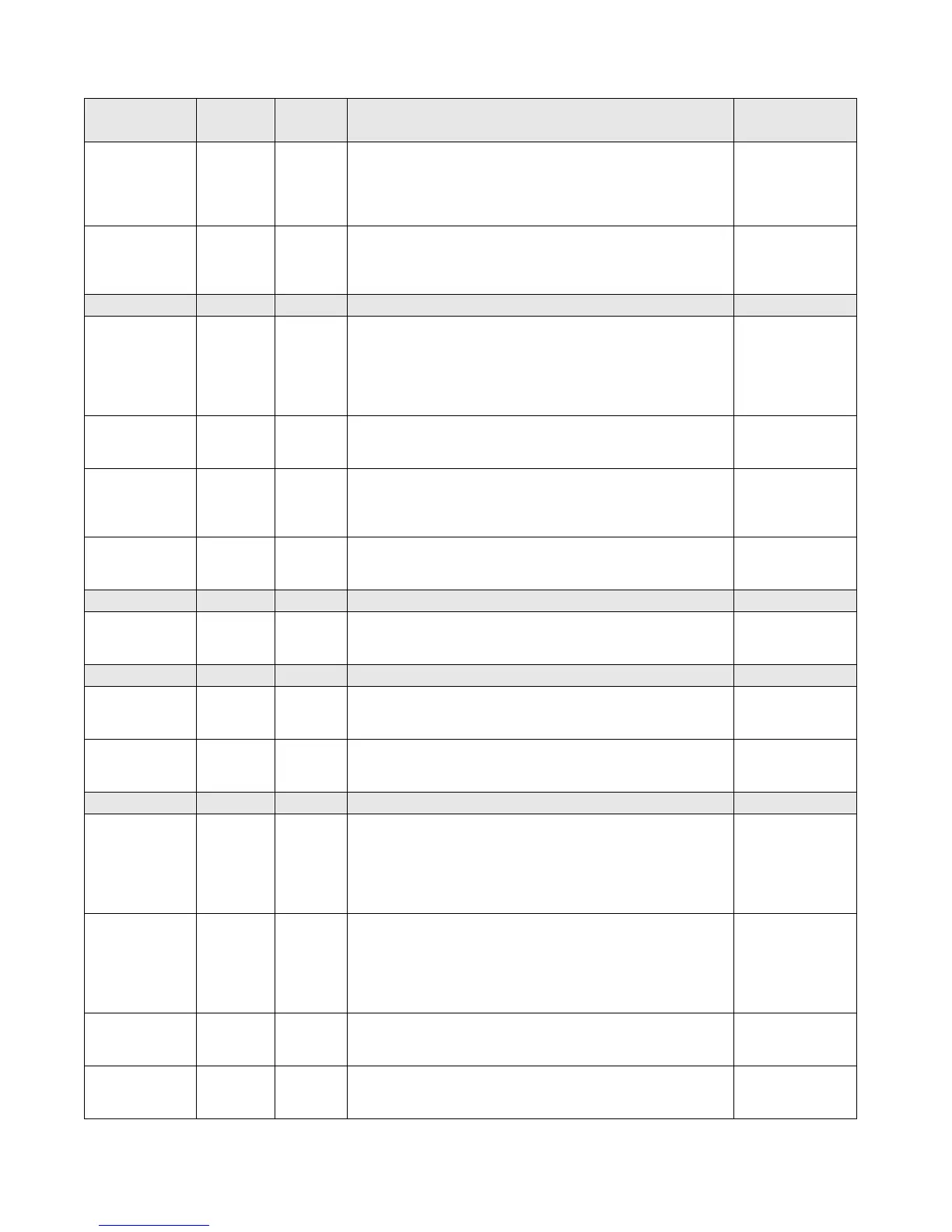

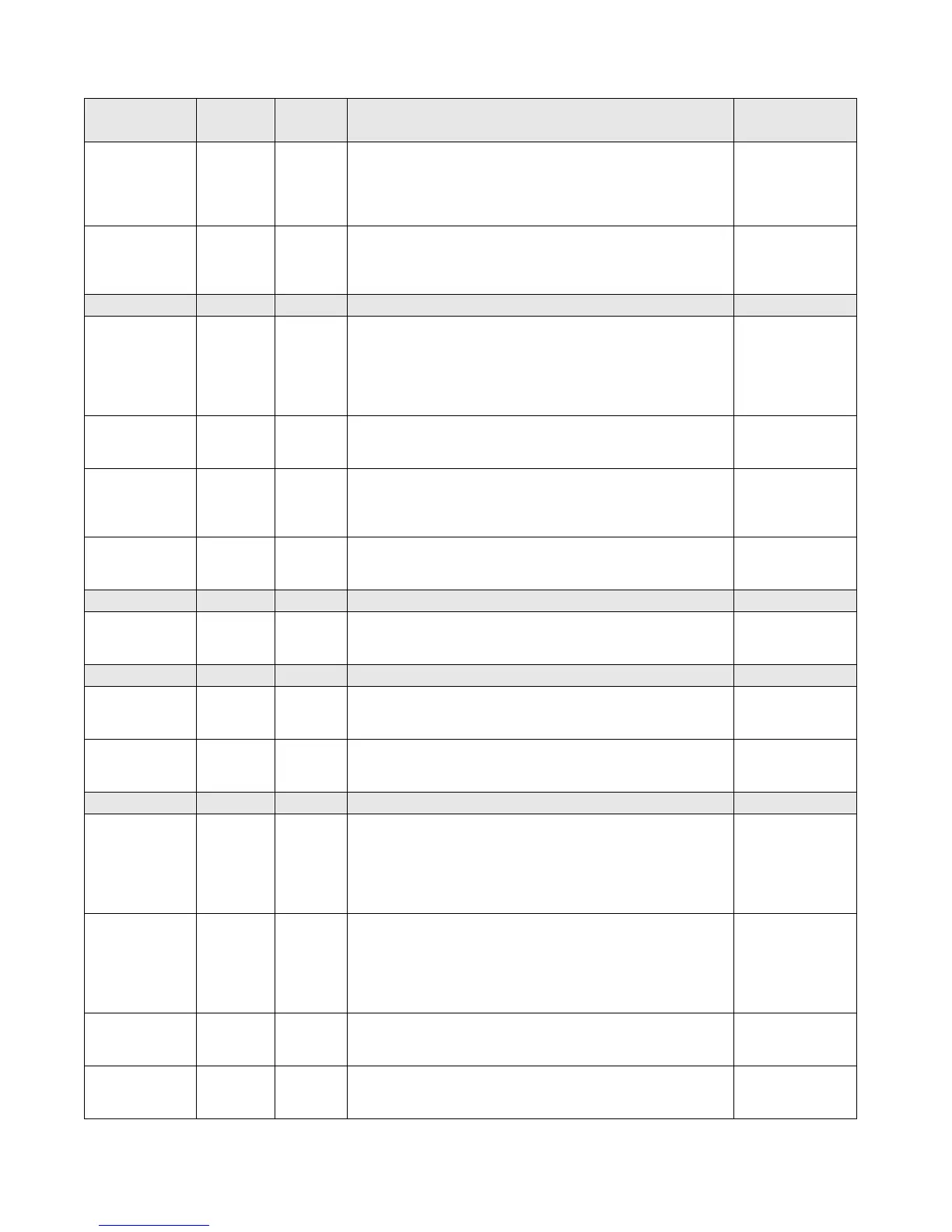

10 - 6 RTHC-IOM-1C

External Current

Limit Setpoint

IFW-AR N/A a. Not “Enabled”: no diagnostics.

b. “Enabled “: Out-Of-Range Low or Hi, set diagnostic, default CLS

to next level of priority (e.g. Front Panel SetPoint. This IFW

diagnostic will automatically reset if the input returns to the normal

range.

Check Signal At

Input

EXV Electrical

Drive Circuit

MMR N/A The Stepper module has detected a wiring or motor fault on the EXV

output circuit just prior to EXV pre-position. The EXV motor is not

driven if a problem is detected. Miswires or faults that occur in the off

cycle can be detected and damage to module prevented at start-up.

Check Stepper

Module, Wiring, &

Motor.

High Cprsr

Discharge Temp.

MMR Immediate a. The discharge temp. exceeded 190

°

F + or - 5

°

F.

b. Time to trip from trip value exceeded shall be 0.5 to 2.0 seconds.

(Note: The trip may be an “instantaneous trip” but consistent with the

analog input filtering function.)

c. Immediate shutdown is preferred over friendly because unloading

the compressor will generally increase the discharge temperature.

See

Troubleshooting

Service Bulletin

High Diff. Rfgt

Pressure

MMR Friendly a. The difference between the Condenser pressure and the

evaporator pressure exceeded 160 PSID for 0.8-5.0 seconds. 152

PSID must hold, 152+ to trip in one hour.

See

Troubleshooting

Service Bulletin

High Evaporator

Liquid Level

MMR Friendly The liquid level sensor is seen to be at or near its high end of range

for 80 continuous minutes while the compressor is running

Check EXV,

Sensor, Stpr

Module & Rfgt

Charge

High Pressure

Cutout Tripped

MMR Immediate A high pressure cutout was detected. C.O. on rise @ 180 psig, reset

at 135 psig (+/-5 psid on switching tolerance) Note: Pressure relief

valve is 200 Psi +/- 2%,

Check Condenser

Water Temp.

High Restart

Inhibit Timer

Warning

IFW N/A The restart inhibit timer has reached a maximum threshold of 15

minutes. This indicates excessive chiller cycling, steps should be

taken to correct this.

Check for

Excessive Chiller

Cycling

Incorrect Chiller

Software Installed

MMR N/A The incorrect EPROM was loaded into this module. This diagnostic

is detected when a factory test computer sets the unit type to

something other than what the EPROM software was intended.

No Message

Required

Incorrect Stepper

Software Installed

MMR N/A The incorrect EPROM was loaded into this module. This diagnostic

is detected when a factory test computer sets the unit type to

something other than what the EPROM software was intended.

No Message

Required

Loss of Oil at

Compressor

(Running)

MMR Immediate In Running modes, Oil sensor detects lack of oil in line i.e. sensor

terminal voltage above 11.5 volts (clamped at 14.0 volts) for 23 volt-

seconds (778 bit for 1600 bit count-seconds). Upon transition from

wet to totally dry, a trip will occur in 15 seconds nominally

(distinguishing a liquid flow from a vapor flow).

Check Oil System

(Master Oil Line

Solenoid Valve &

Oil Return System

& Oil Detector

Sensor)

Loss of Oil at

Compressor

(Stopped)

MMR Oil Sensor detects a lack of oil trapped in line feeding compressor

for 2 continuous minutes after the oil line solenoid is opened for pre-

start mode. Note: Compressor start is delayed (up to an additional

90 sec) from the normal 30 sec of pre-start, waiting for oil to be

detected

Check Oil System

(Master Oil Line

Solenoid Valve &

Oil Return System

& Oil Detector

Sensor)

Low Chilled

Water Temp: Unit

Off

IFW-AR N/A a. The chilled water temp. fell below the cutout setpoint while the

compressor was not running for 30

°

F Seconds. Automatic Reset of

the IFW diag shall occur 2

°

F (1.1

°

C) above the cutout setpoint.

Check Flow,

Sensor, Wiring and

Rapid Load Loss

Low Chilled

Water Temp: Unit

On

MAR Friendly a. The chilled water temp. fell below the cutout setpoint while the

compressor was running for 30

°

F Seconds. Automatic Reset of the

MAR diag shall occur 2

°

F (1.1

°

C) above the cutout setpoint.

Check Flow,

Sensor, Wiring and

Rapid Load Loss

Diagnostic

Description

Diagnostic

Type

Shutdown

Action

Cause Help Message

Loading...

Loading...