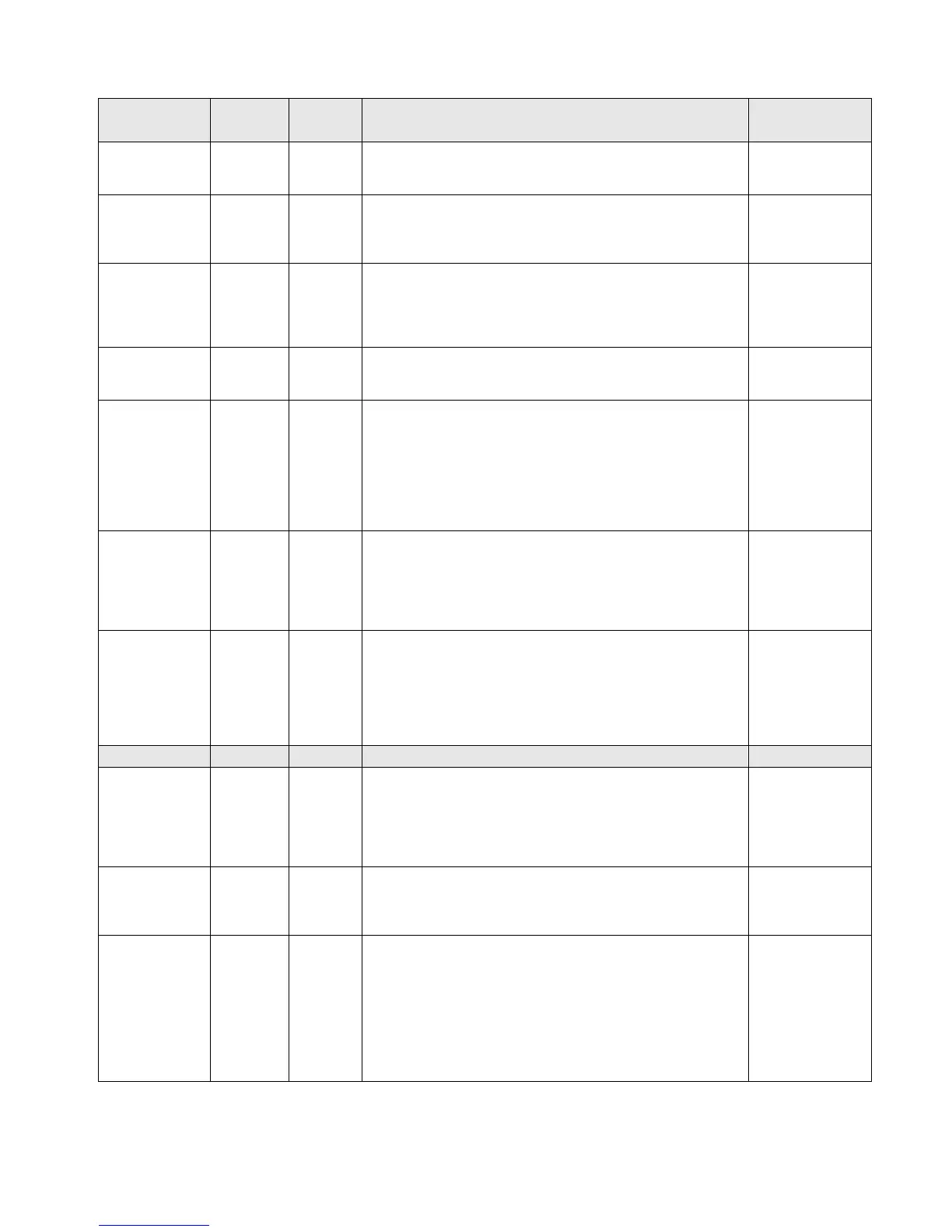

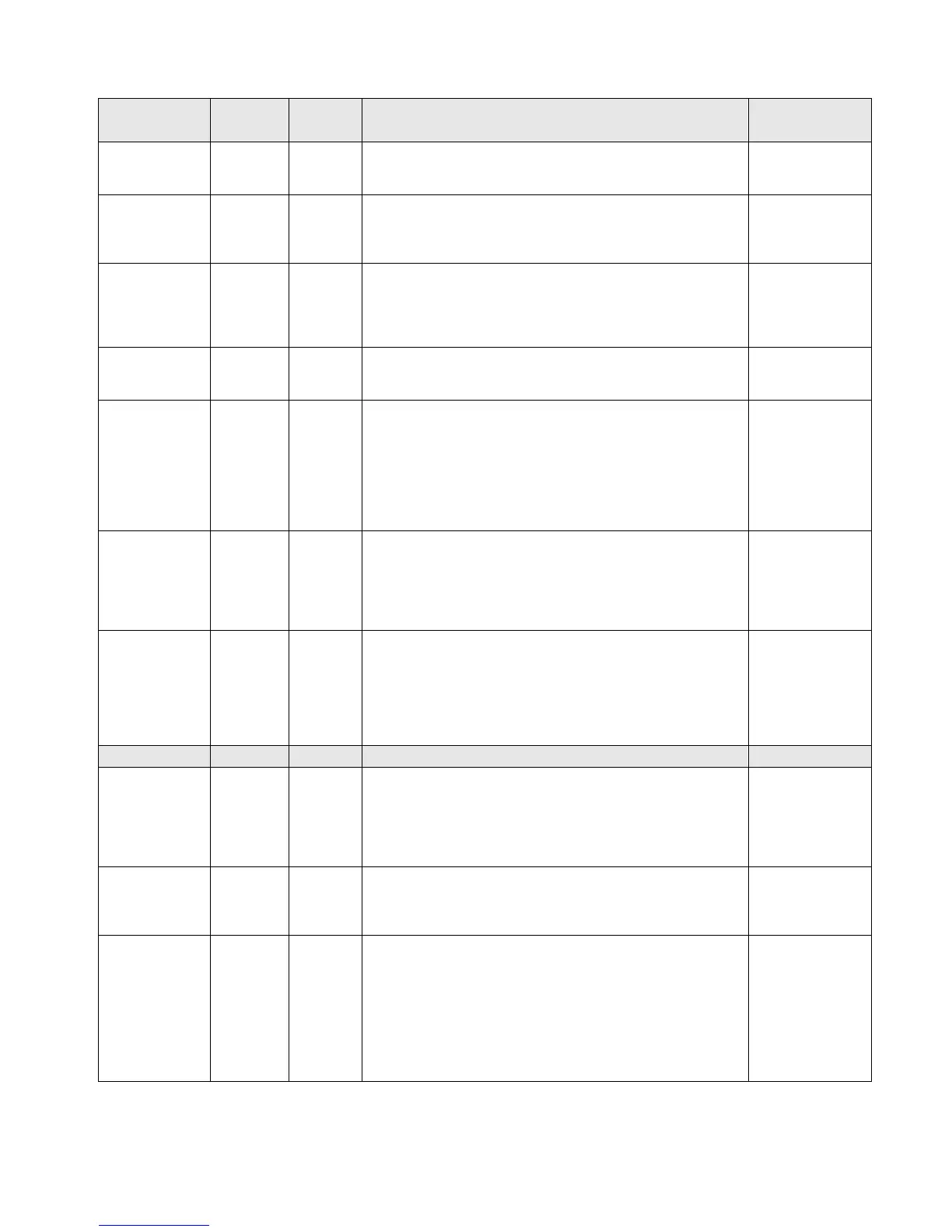

Installation, Operation and Maintenance 10 - 7

Low Differential

Rfgt Pressure

MMR Friendly A low differential temperature/pressure condition was detected that

lasted for more than 240 continuous seconds. The trip point is 23.8

psid.

Check Condsr

Water Temp Too

Low and EXV

Low Differential

Refgt Press

Switch

MAR N/A If the 7.7 psid system differential pressure switch is not open on the

attempt to start, the MAR diagnostic will keep the unit latched out

until the switch is opened.

Check Low

Differential

Pressure Switch &

its Valving, EXV

Low Discharge

Superheat

MMR Friendly a.While Running Normally, the Discharge Superheat was less than

12

°

F +/- 1

°

F for more than 6500

°

F seconds. The must hold value is

13

°

F while the must integrate value is 11

°

F.

b. At start-up the UCP2 shall ignore the Discharge Superheat for a

minimum of 5 minutes and a maximum of 5.5 minutes.

See

Troubleshooting

Service Bulletin

Low Evaporator

Liquid Level

MMR Friendly The liquid level sensor is seen to be at or near its low end of range

for 80 continuous minutes while the compressor is running

Check EXV Sensor,

Stpr Module & Rfgt

Charge

Low Evap Rfgt

Temp.

MMR Immediate a. The Saturated Evap Rfgt Temp dropped below the Low Rfgt

Temp. Cutout Setpoint when the circuit was running for 60

°

F

seconds. The diagnostic is ignored during the first minute of

operation after a start. Special Note: During time-out of trip integral,

the unload solenoid is energized continuously and the load solenoid

de-energized continuously. Normal load/unload operation is

resumed if the trip integral is reset by return to temperatures above

the cutoff setpoint.

Check Oil Sump

Vent Line Valve, Oil

Return System.

Check for Oil

Overcharge

Low Oil Flow MMR MMR The oil flow pressure switch detects no flow (high differential

pressure/high logic state) for 5 continuous seconds while running.

Check Oil System

(Master Oil Line

Solenoid Valve &

Oil Filter, Hand

Valves and Diff.

Pressure Switch)

Low Pressure

Cutout

MMR Immediate The Low Pressure Cutout opened for more than 0.5-2 Seconds.

C.O. on fall @ 0 psig (+/- 3 psi), reset @ 20 psig (+/-5psi). The LPC

is set primarily to detect significant charge loss and thus ignore

times at start-up are not required (The sat evap temp sensor is used

for low temp / low pressure detection but it cannot function if

saturated conditions are not present such as in the event of charge

loss)

See

Troubleshooting

Service Bulletin

Max Acceleration

Setpts

Error

IFW N/A a. The redundant Maximum Acceleration settings did not agree for

30 continuous seconds. (Continue to use the previous value for the

30 second time-out.) When this diagnostic occurs, the affected

Starter Module shall use 6 seconds as a default until either the

UCP2 is reset or, if the redundant settings agree again, the starter

module can go back to using the actual setting.

Review Max

Acceleration Set Up

Memory Error

Type IV

IFW N/A A page time-out error was detected while trying to write data into

EEPROM. There will likely be a recall of Engineering ROM defaults

on the next reset or power transition. Replace the Chiller Module as

soon as a replacement is available.

Call Service to

Check all Settings

Memory Error

Type II: Shadow

RAM

IFW N/A a. A Shadow RAM memory error was detected. The UCP2 is

operating on all last valid values (pulled from NOVRAM) for all setup

parameters. No setup parameter changes were pending to be

loaded into NOVRAM, a complete recovery of all setup parameters

was made and there is no need to check unit setup parameters.

Compressor starts and hours were lost for not more than the last 24

hours. This is expected to be an isolated event and repair or

replacement is not required. If this diagnostic occurs repeatedly,

then replace the Chiller module.

No Settings Were

Lost

Diagnostic

Description

Diagnostic

Type

Shutdown

Action

Cause Help Message

Loading...

Loading...