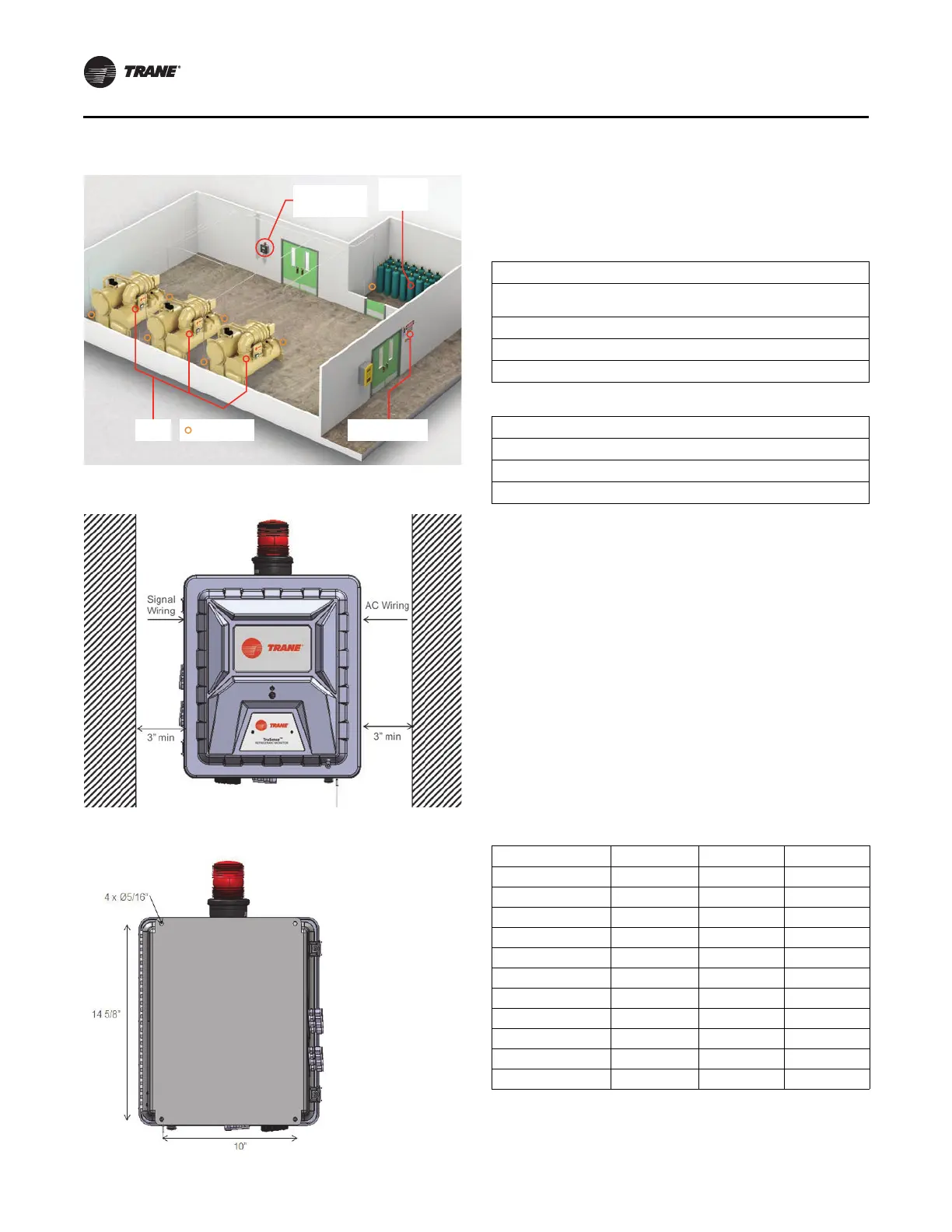

Figure 7. Mounting location

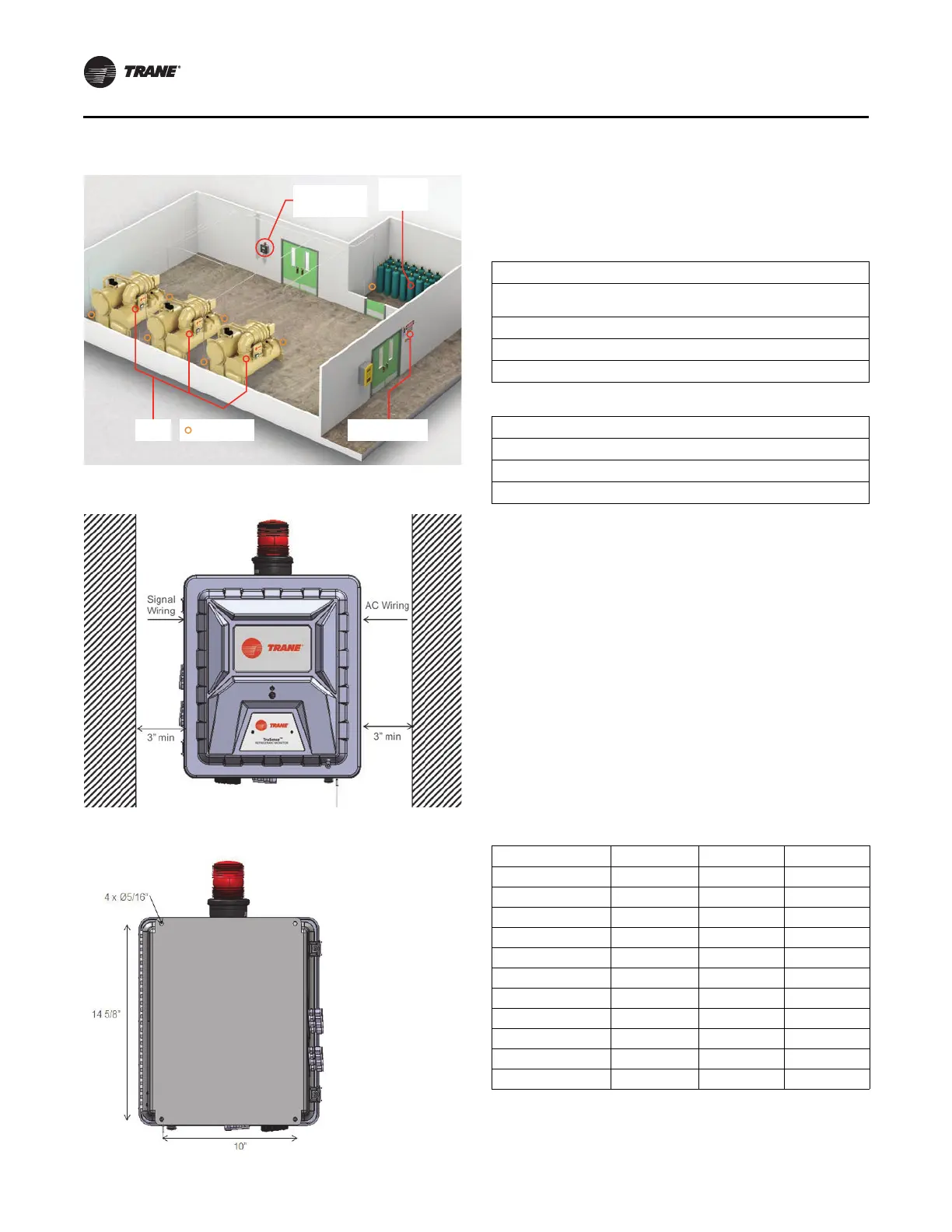

Figure 8. Front of device

Figure 9. Rear of device

Installation

12 RMWH-SVX001C-EN

Sample and Exhaust Lines

Tubing Material

The device can use hard and soft tubing. The following are

acceptable tubing types:

Imperial (I-P) Units

1/4-in. OD x 1/8-in. inside diameter (ID) Polyurethane tubing (ether-

based)

1/4-in. OD x 3/161/4-in. ID Polyuret

hane tubing (ether-based)

1/4-in. OD Copper tubing

1/4-in. OD Stainless steel tubing

International System (SI) Units

6-mm OD x 4-mm ID Polyurethane tubing (ether-based)

6-mm OD Copper tubing

6-mm OD Stainless steel tubing

Note: Use the appropriate tools to give a clean, smooth

end to the tubing when it is cut.

Routing and Placement

Trane recommends the use of at least two gas-monitoring

points per chiller for sufficient detection monitoring. Due

to installation and application variations, each system

must be analyzed individually.

Do a smoke test of the mechanical

room to determine the

flow patte

rn and allow for optimal placement of the

sample lines. For a list of approved parts and how to order

them, refer to “Ordering Information,” p. 52.

Keep the total line length of a

poi

nt, including the sample

line and exhaust line, at less than 1200 ft (366 m). Keep

lines as short as possible to minimize the transport time of

the device.

Table 4. Transport time

Line Length (ft) 4 pts 8 pts 16 pts

0 19 s 19 s 19 s

50 19 s 19 s 19 s

100 19 s 19 s 19 s

150 19 s 19 s 19 s

200 19 s 19 s 19 s

250 19 s 19 s 19 s

300 1 m 35 s 2 m 51 s 5 m 23 s

350 1 m 35 s 2 m 51 s 5 m 23 s

400 2 m 51 s 5 m 23

s 10 m 27 s

450 2 m 51 s 5 m 23 s 10 m 27 s

500 2 m 51 s 5 m 23 s 10 m 27 s

Note: Transport time is similar for all tubing

configurations.

TruSense

Refrigerant Monitor

Refrigerant

Storage

Chillers Sampling Points Entry Way Signalling

Loading...

Loading...