Installation

RMWH-SVX001C-EN 13

Typically, refrigerants collect near the floor. Install the

sample points 12–18 in. (30–46 cm) above the floor.

For installations where water condens

ation in the sample

l

ines is likely, Trane recommends installing a water trap

filter such as a Parker P/N F504-01AHX67 or equivalent.

End-of-Line Filters

WARNING

Risk of Asphyxiation!

Failure to follow instructions below could cause

inaccurate readings and improper gas monitoring

which could result in death or serious injury.

Use and maintain end-of-line filters to ensure proper

readin

gs and prevent damage to internal components.

Make additional servicing necessary.

Install an end-of-line filter (Trane P/N FLR04743) in each

sample line to decrease contaminants in the sample lines

and device.

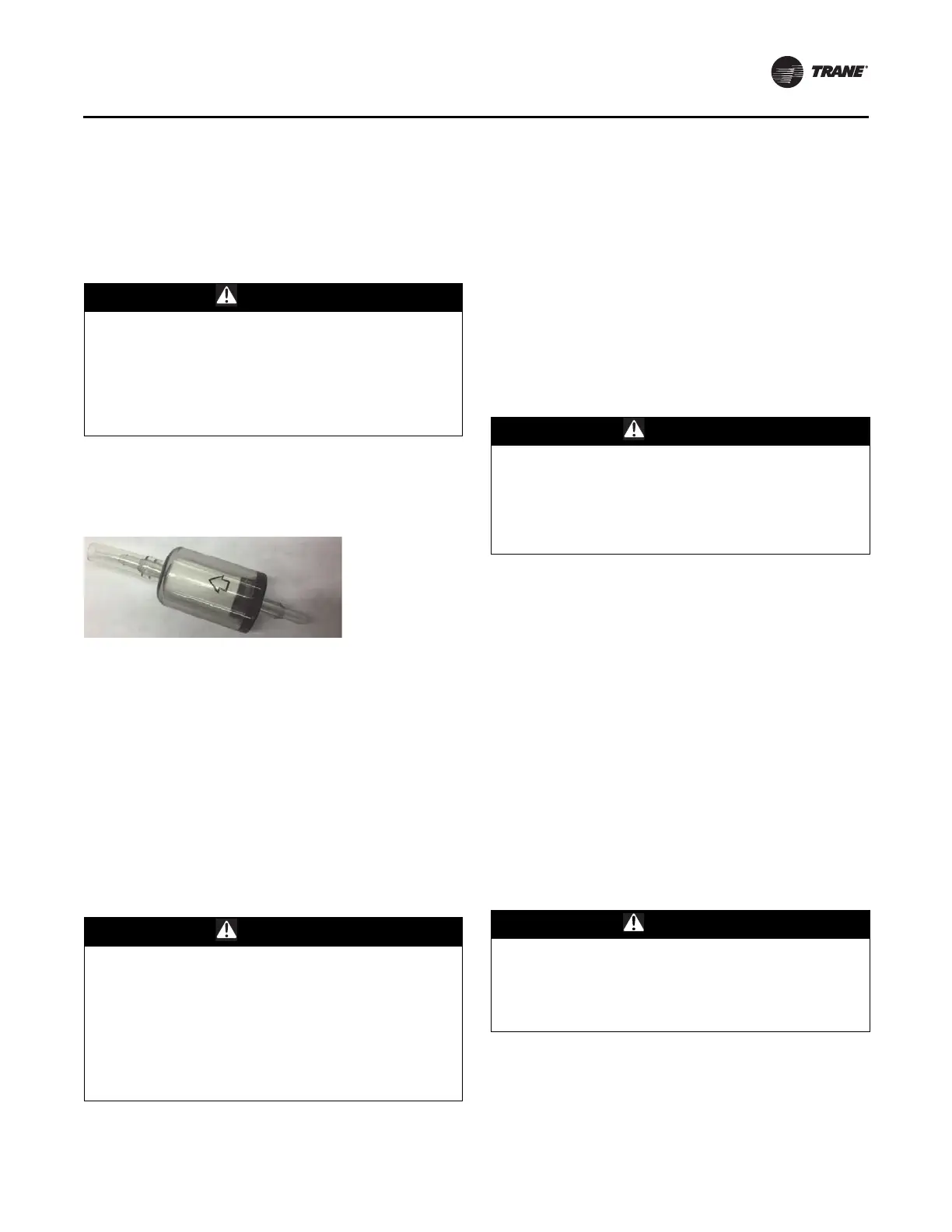

Figure 10. End-of-line filter

Do the following procedure to install end-of-line filters:

1. Remove the new

end-of-line filter from the bag.

2. Slide the end of the end-of-line filt

er wi

th flexible

tubing onto the sample line tubing. Make sure the

arrow on the body of the filter (refer to Figure 10) points

in the direction of air flow into the sample line.

Examine and replace the end-of-line filters at regular

intervals. The appropri

ate interval for replacement is

determined by the environment of the installation.

For a list of approved parts and how to order them, refer to

“Ordering Information,” p. 52.

Connections

WARNING

Risk of Asphyxiation!

Failure to follow instructions below could cause

inaccurate readings and improper gas monitoring

which could result in death or serious injury.

Install tubing with large enough b

end radii to prevent

kinking or pinching. Kinking or pinching of the tubing

could result in insufficient monitoring of an area. Before

connecting tubing to the device, clean all tubing with

compressed air or nitrogen to remove debris.

The device has Swagelok® compression fit

tings fo

r

connections to the sample and exhaust lines. These

fittings accept the hard and soft tubing specified in

“Tubing Material,” p. 12.

Do the following procedure to connect the sample and

exha

ust lines:

1. Remove the cap from the compression fitting.

2. Insert the tubing fully

into the compression f

itting and

against the shoulder.

3. Turn the nut until i

t is

finger-tight on the tubing.

4. Mark the nut at the 6 o’clock position.

5. While holding the body of the f

itting steady, tighten

the

nut 1-1/4 turns to the 9 o’clock position.

Exhaust Venting

WARNING

Risk of Asphyxiation!

Failure to follow instructions below could cause

inaccurate readings and improper gas monitoring

which could result in death or serious injury.

Make sure to remove the cap from the exhaust port

before operating the device.

The use of exhaust tubing reduces pump

noise from the

device.

Make sure to vent the exhaust of the device to the outside

atmosphere (preferred) or

a safe area.

Do not use inline or end-of-line filters in the exhaust line.

If possible, route the exhaust line so venting

occurs to the

outsi

de atmosphere. Make sure to protect the end of the

exhaust tube from elements such as water, dirt, snow, ice,

and insects, which can cause clogs and prevent efficient

venting.

If exhaust venting occurs indoors, make sure to route the

e

xhaust line to:

• An area that is not monitored for refrigeran

t gases

• An area away from personnel

Wiring and Grounding

WARNING

Proper Grounding Required!

Failure to follow instructions below could result in

death or serious injury from electrocution.

Make sure the device chassis is connected to the earth

ground at the ground bar.

Note:

• In

stallations that require conformity

to the CE mark

must have a connection between the TruSense™

RMWH Refrigerant Monitor device and a nearby earth

ground potential.

Loading...

Loading...