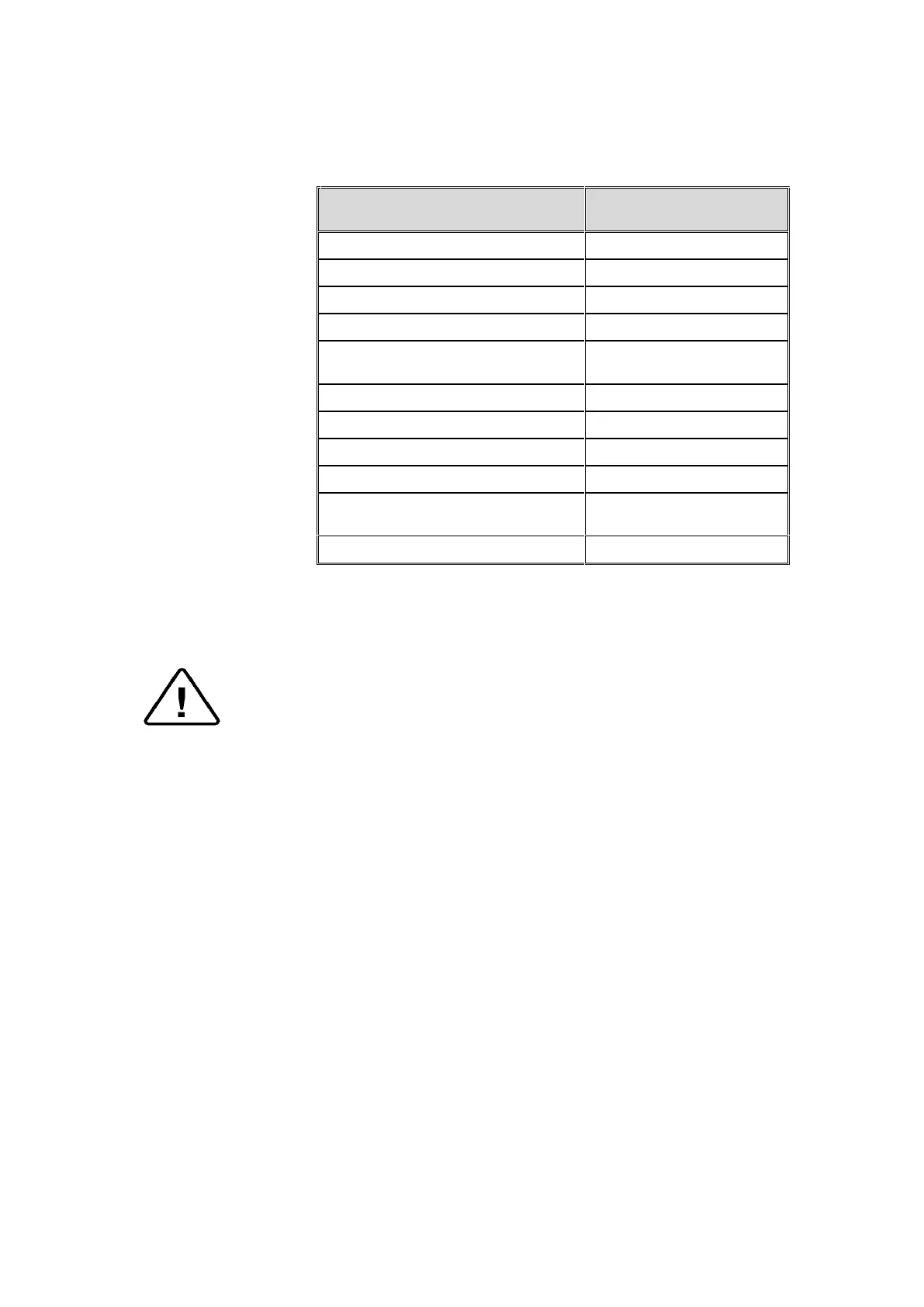

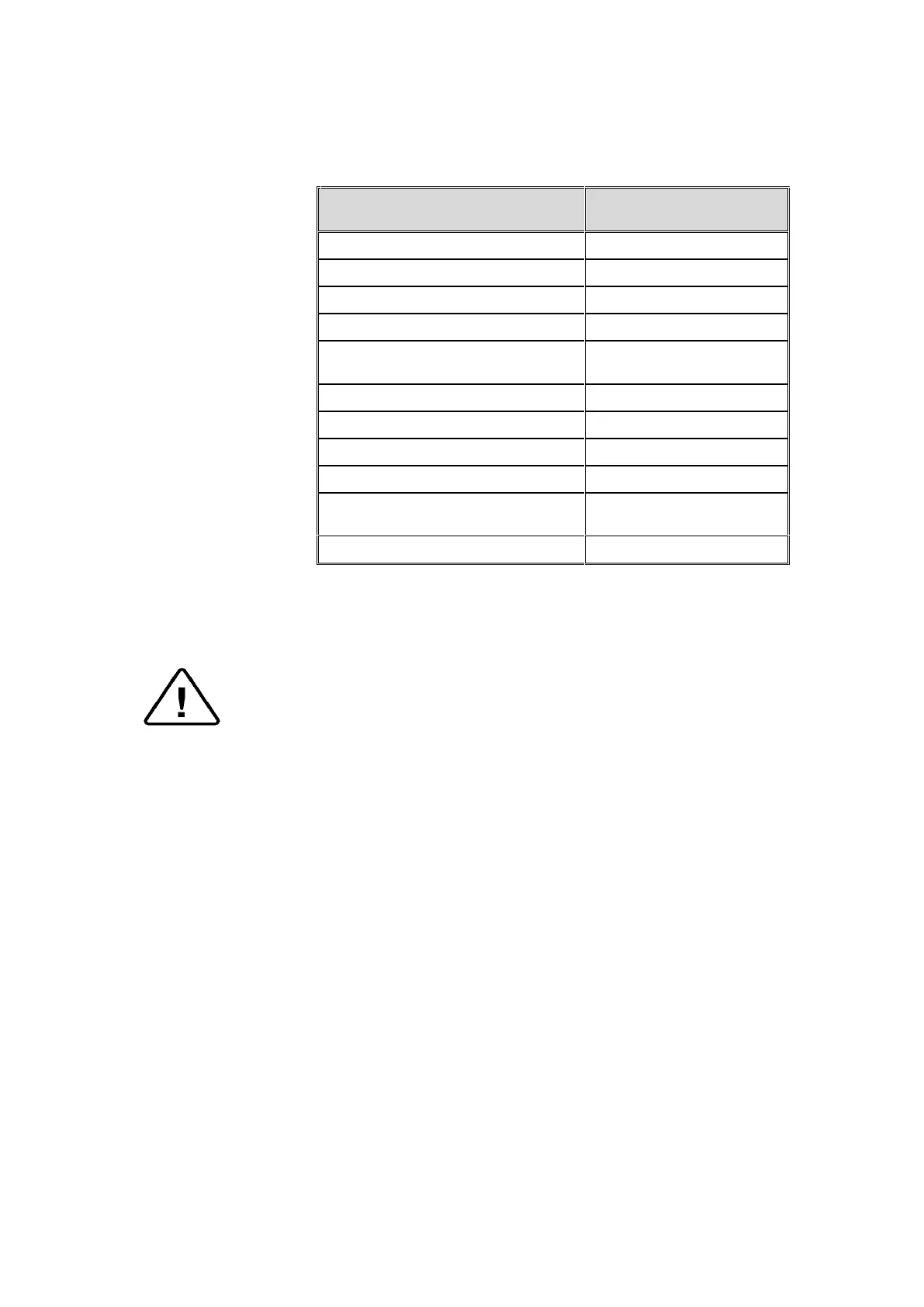

Physical Characteristics and Maximum acceptable

contaminants levels in steam for sterilizers

(According to EN 13060:2004).

Compliance with the above data should be tested in accordance

with acknowledged analytical methods, by an authorized

laboratory.

Attention:

We recommend testing the water quality once a month. The use of water

for autoclaves that does not comply with the table above may have severe

impact on the working life of the sterilizer and can invalidate the

manufacturer’s guarantee.

3.11.2 Drain Cooling

The feed water supplied to the drain cooling must meet the

following requirements:

Hardness: 0.7 - 0.2 mmol/l.

Water temperature shall not exceed 15°C (59°F).

3.11.3 Reverse Osmosis

A Reverse Osmosis (RO) system may be used to improve the

quality of the water used to generate steam in the autoclave

chamber.

In RO, the water is forced through a semi-penetrable membrane,

which filters out contaminants to a high degree of efficiency. In

deionisation (DI) ions and charged particles are removed either

by electric fields or by ion exchange in resin beds.

Loading...

Loading...