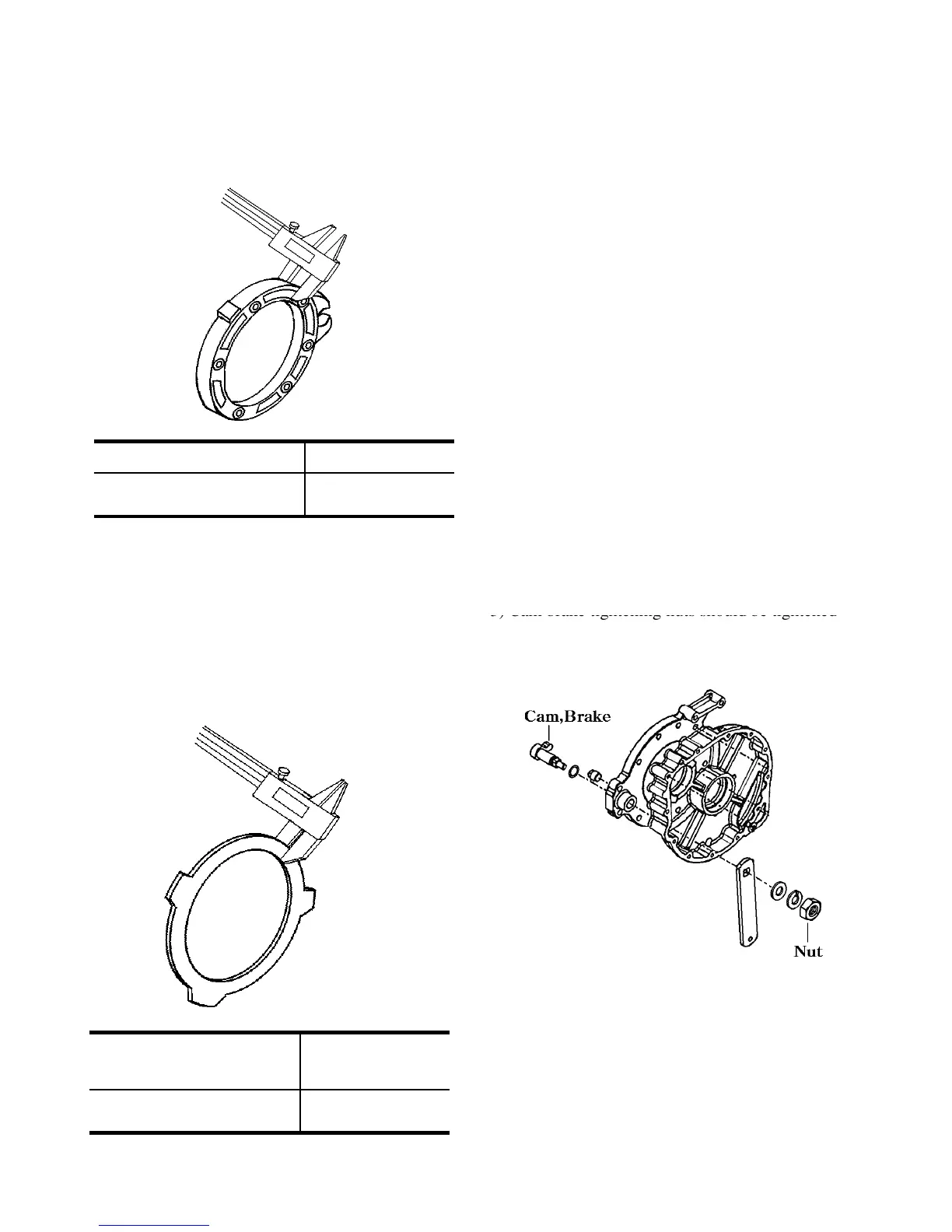

2) Metal brake

Check the pressure plate,and brake rod for

abnormality.Replace defective parts.Replace the

metal brake whose thickness exceeds the usable

limit.

Standard thickness:mm(in) 18(0.708)

Usable limit:mm (in) 17.5((0.688)

Note:

Slight scratches on the friction surface can be

corrected with sandpaper(#1000)

Fig.7-8

4) Wheel shaft

Check the shaft for abnormalities like wear,

damage,etc,and replace a defective one.

5) Bearings

Check them for abnormalities like hitching,

irregularity,etc.in rotation after being washed

clean.Replace defective ones.

6) Oil seals

Removed oil seal should be replaced with a new

one when reassembled.

1.3 REASSEMBLY.

Reassemble the parts in reverse order of

disassembly ,follow these precautions.

1) Make sure that oil grooves,friction surfaces,etc

of the brakes are free from matter such as dust,

iron powder,etc.to avoid brake lining damage.

2) When installing the brake unit on the wheel

pinion,friction plates and separator plates

should be arranged in correct order and never

forget to retain the unit with the snap ring.

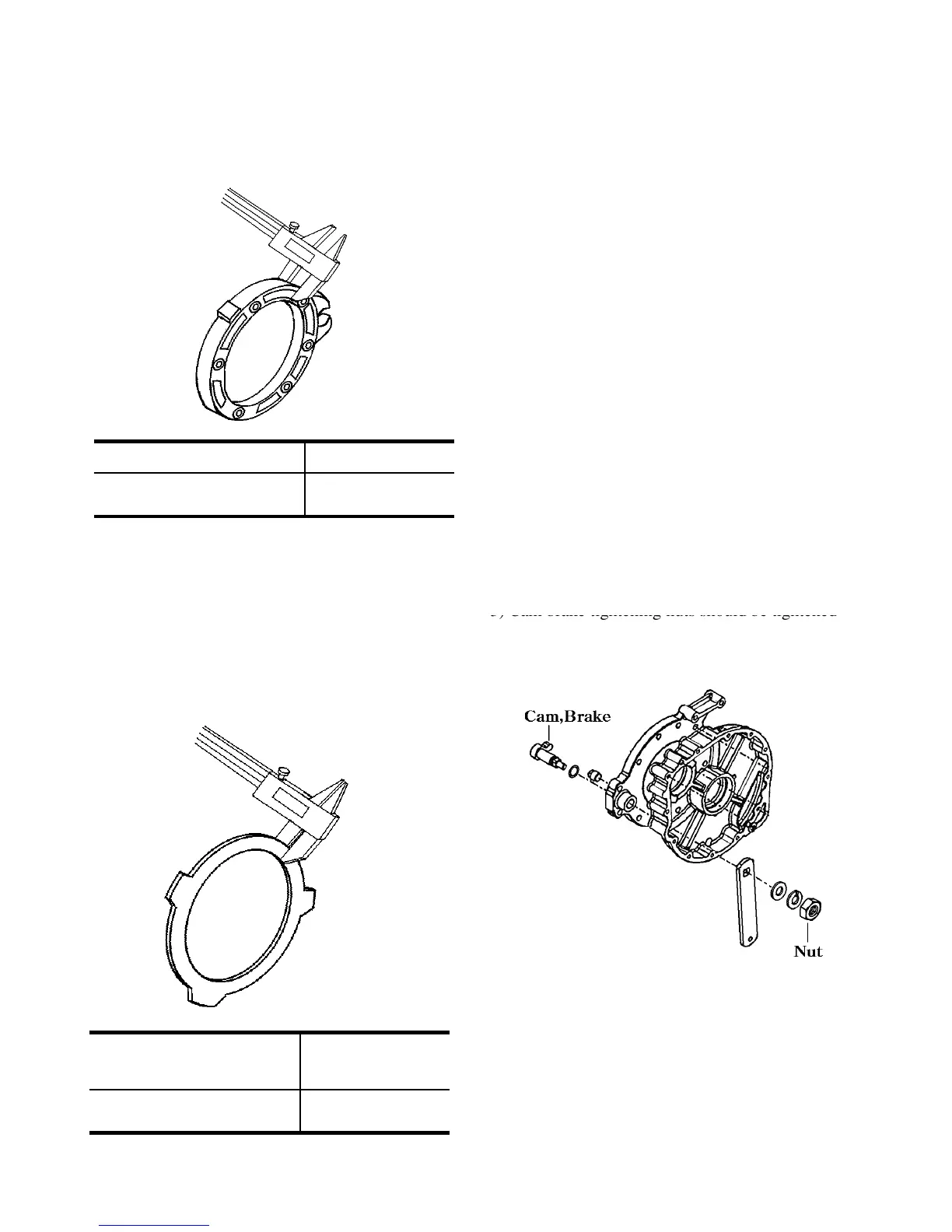

3) Separator plate.

Measure the thickness and replace the plate whose

thickness exceeds the usable limit or whose

surfaces are damaged (Fig.7-9)

Fig.7-9

Standard thickness:mm(in) 2.5±0.09

(0.098)

Usable limit:mm (in) 2.2(0.087)

7-5

to the specified torque with a torque wrench.

(Fig.7-10)

(Fig.7-10)

4) Replace the oil seal.

Install the bearing,snap ring,and collar into the axle

housing,and then press in the oil seal by applying

force only to the circumference as shown in the

figure( Fig.7-11)

Loading...

Loading...