-

15

-

IV. Operation Preparation

Please turn off the power switch and confirm that the motor has stopped before operation to

prevent personal injuries caused by unexpected start.

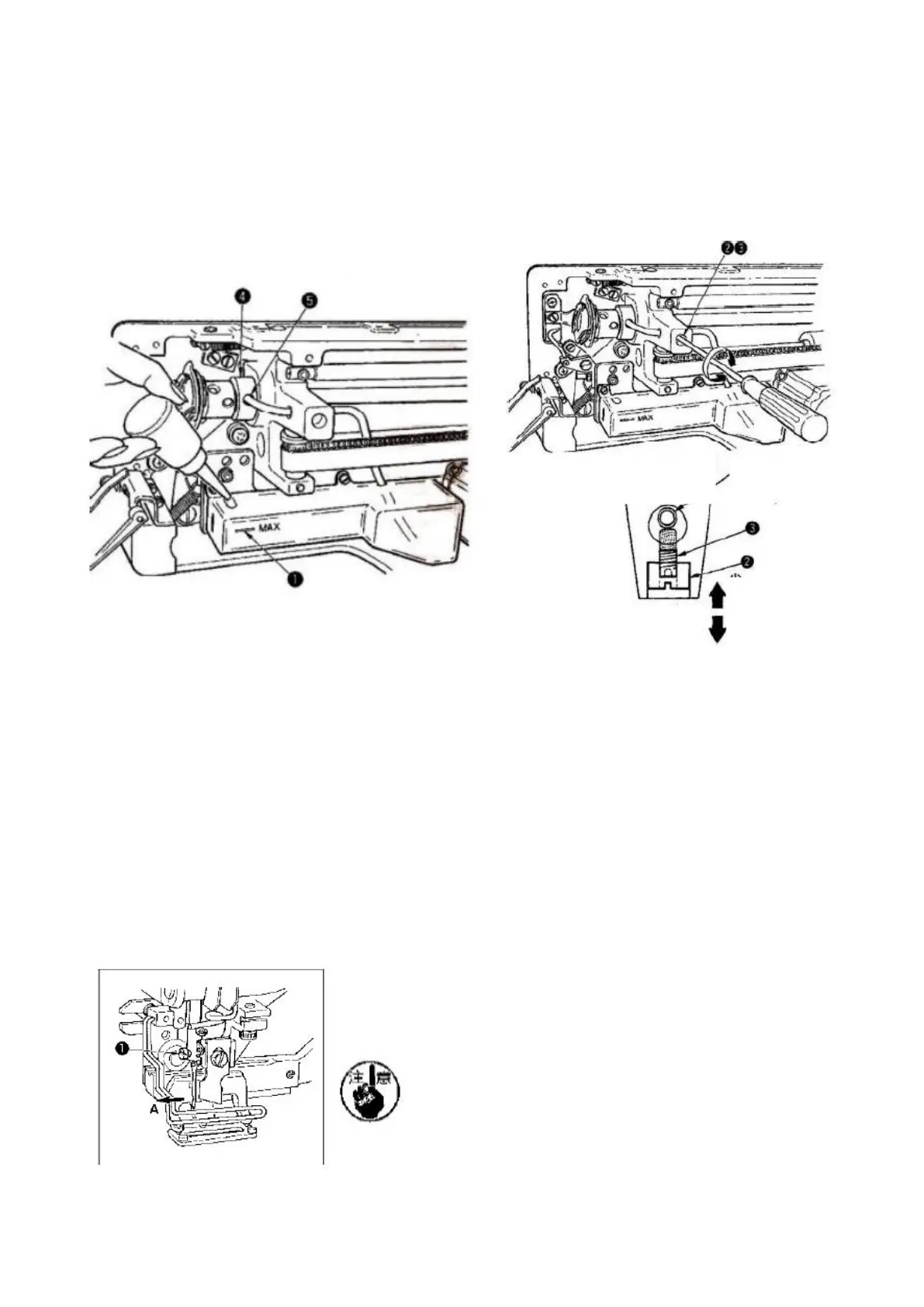

1) Lubricating oil to oiling tank

♦ Fill the oiling tank with New Defrix Oil No.1 up to the level indicated by MAX ①.

2) Adjust the lubrication for the sewing hook

♦ The amount of oil is adjusted with oil amount adjusting screw②.

♦ Amount of supplied oil is reduced when turning the screw② clockwise.

♦ For newly-installed sewing machine or sewing machine out of service for a long time, please remove

the bobbin case and drip 2-3 droplets of oil on the side slots of the cover. In addition, drip several

droplets of oil into the oiling hole in the metal parts③ in front of the lower shaft, and make the oil

infiltrate into the felt inside the hole.

Please turn off the power switch and confirm that the motor has stopped before operation to

prevent personal injuries caused by unexpected start.

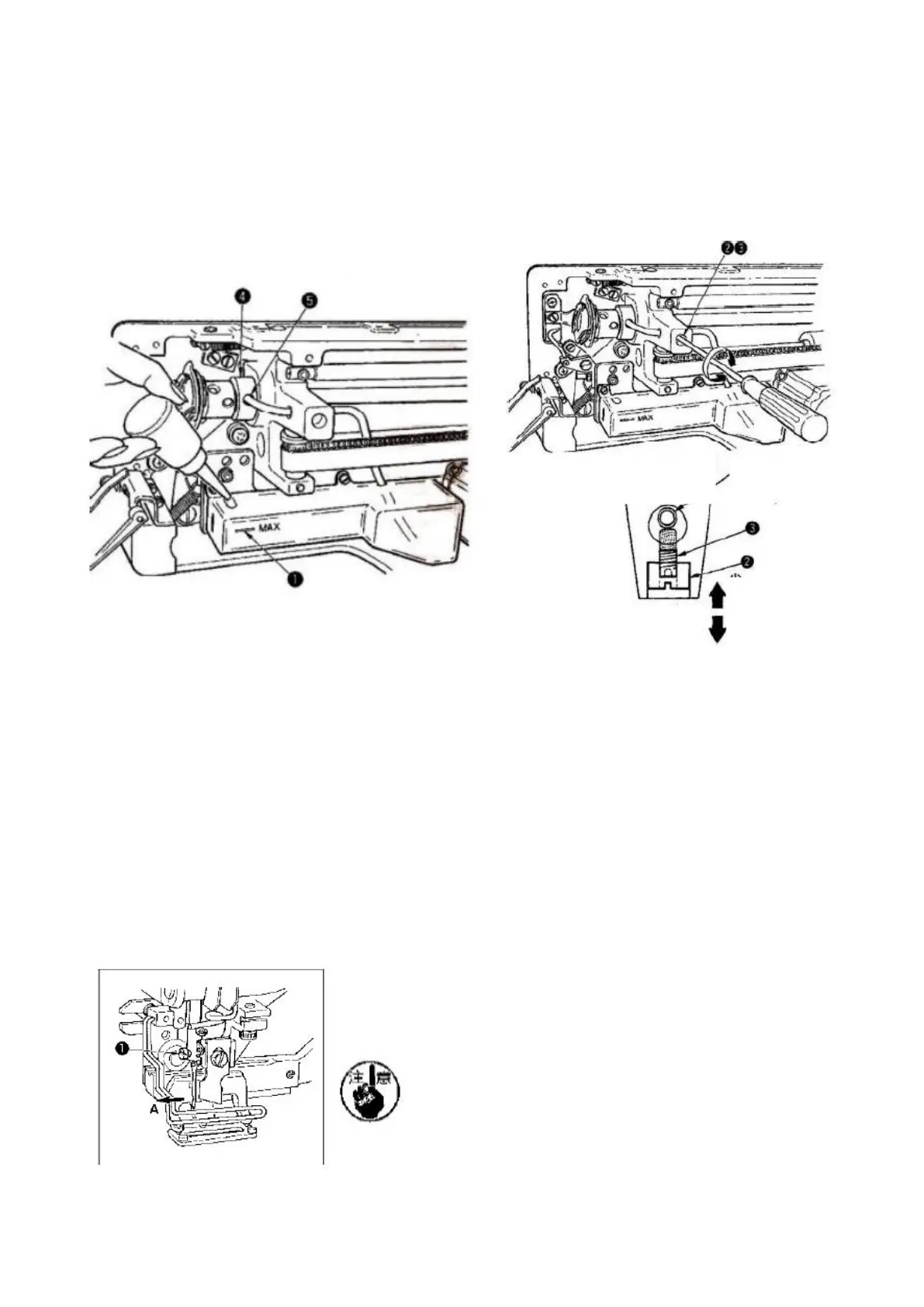

Hold needle with its recessed part facing toward the operator side A.

Then deeply insert the needle into the needle bar hole and tighten the

needle setscrew①.

Use a DPX5-(#11J, #141) needle.

Turn off the power switch before attaching the needle.

Loading...

Loading...