-

79

-

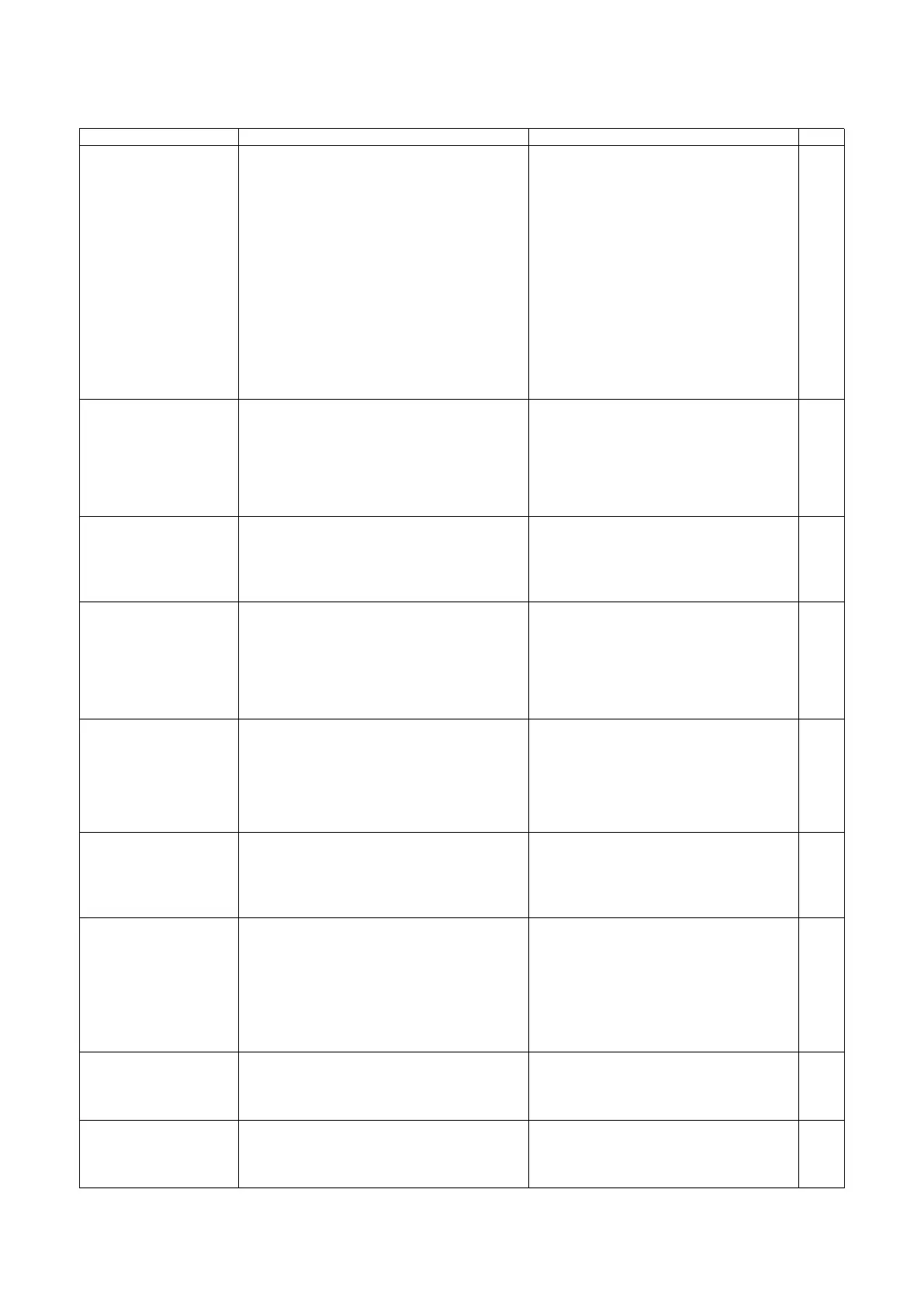

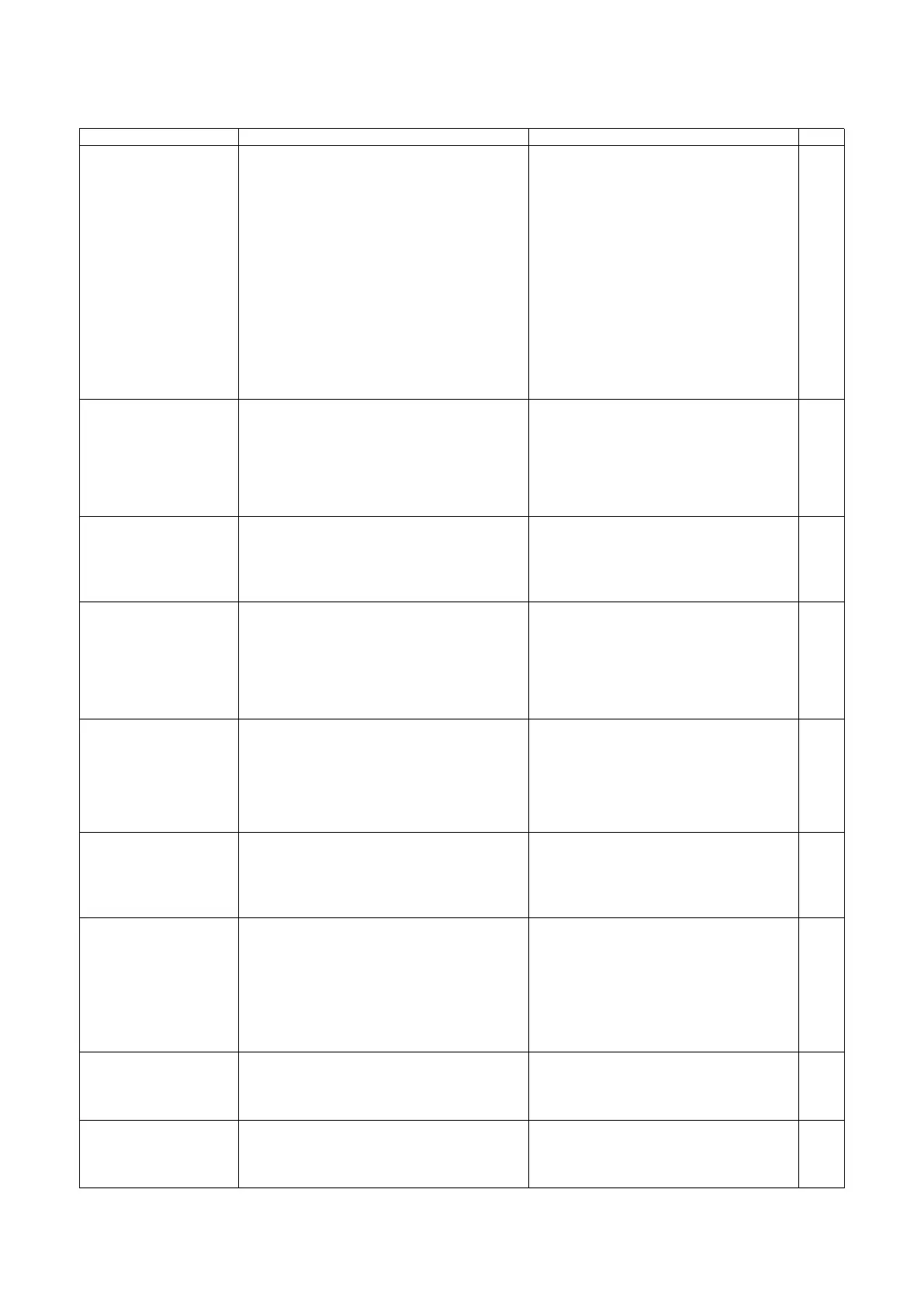

IX. Trouble and Corrective Measures

1. Thread tension at parallel section is too

Decrease the thread tension at parallel

2. Thread take-up spring tension is too strong

Decrease the tension of the thread

take-up spring or decrease its stroke.

3. There is a burr or scratch on the blade

Buff the blade point of hook, or

4. Hook timing is not proper.

Adjust the timing of hook by use of

5. There is a scratch on the thread path.

Polish the thread path with sand paper

6. Attaching needle is wrong.

Adjust again the direction, height, etc.

Replace the needle with a thicker one.

8. Needle tip is damaged.

9. Thread breaks when it is bent

Do not pass the thread through the

1. Needle thread trimmer opens too early.

Needle thread clamp opens too late

during needle thread cutting.

2. Whip stitching is not formed at the start of

Decrease tension at the start of sewing.

(Tension at the start of sewing is too high.)

3. Threading needle thread is wrong.

4. Speed at the start of sewing is too fast.

Set the soft-start function.

1. Decrease the thread tension at parallel

Increase the thread tension at parallel

2. Bobbin thread tension is too high.

Decrease tension of the bobbin thread.

(Purl stitch: 0.05 to 0.1N)

1. Decrease the thread tension at parallel

Increase the thread tension at parallel

2. Position of needle thread trimmer is too

Lower the needle thread trimmer to

such an extent that it does not come in

contact with the presser.

3. Stroke of thread take-up spring is too

Decrease the stroke of thread take-up

appears on the

wrong side of

material at

bar-tacking section

in dumpling

condition.

1. Bar-tacking thread tension is too low.

Increase the bar-tacking thread tension.

2. Bobbin thread tension is too high.

Decrease tension of the bobbin thread.

3. Number of stitches is large due to radial

Decrease the number of stitches.

4. Tension at the end of sewing is too low.

Increase tension at the end of sewing.

1. Bobbin thread tension is too high.

Increase the bobbin thread tension.

2. Bobbin thread comes off bobbin case

Perform proper threading the bobbin

Take care that the winding amount of

bobbin thread is not excessive.

1. Button hole is small in terms of the size of

Replace the presser with a smaller one.

2. Material flops because of light-weight.

Delay the hook-to-needle timing.

(Lower the needle bar by 0.5mm)

3. Attaching needle is wrong.

Adjust again the direction, height, etc.

5. There is a burr or scratch on the blade

Buff the blade top of hook. Or, replace

1. Number of stitches of the stitching is too

Increase the number of stitches of tie

stitching at the end of sewing.

2. Width of tie stitching is too wide.

Narrow the width of tie stitching at the

thread remaining at

the end of sewing

is too long.

1. Width of tie stitching is too narrow.

Widen the width of tie stitching at the

2. Tension of tie stitching is too low.

Increase the tension at the end of

Loading...

Loading...