-

67

-

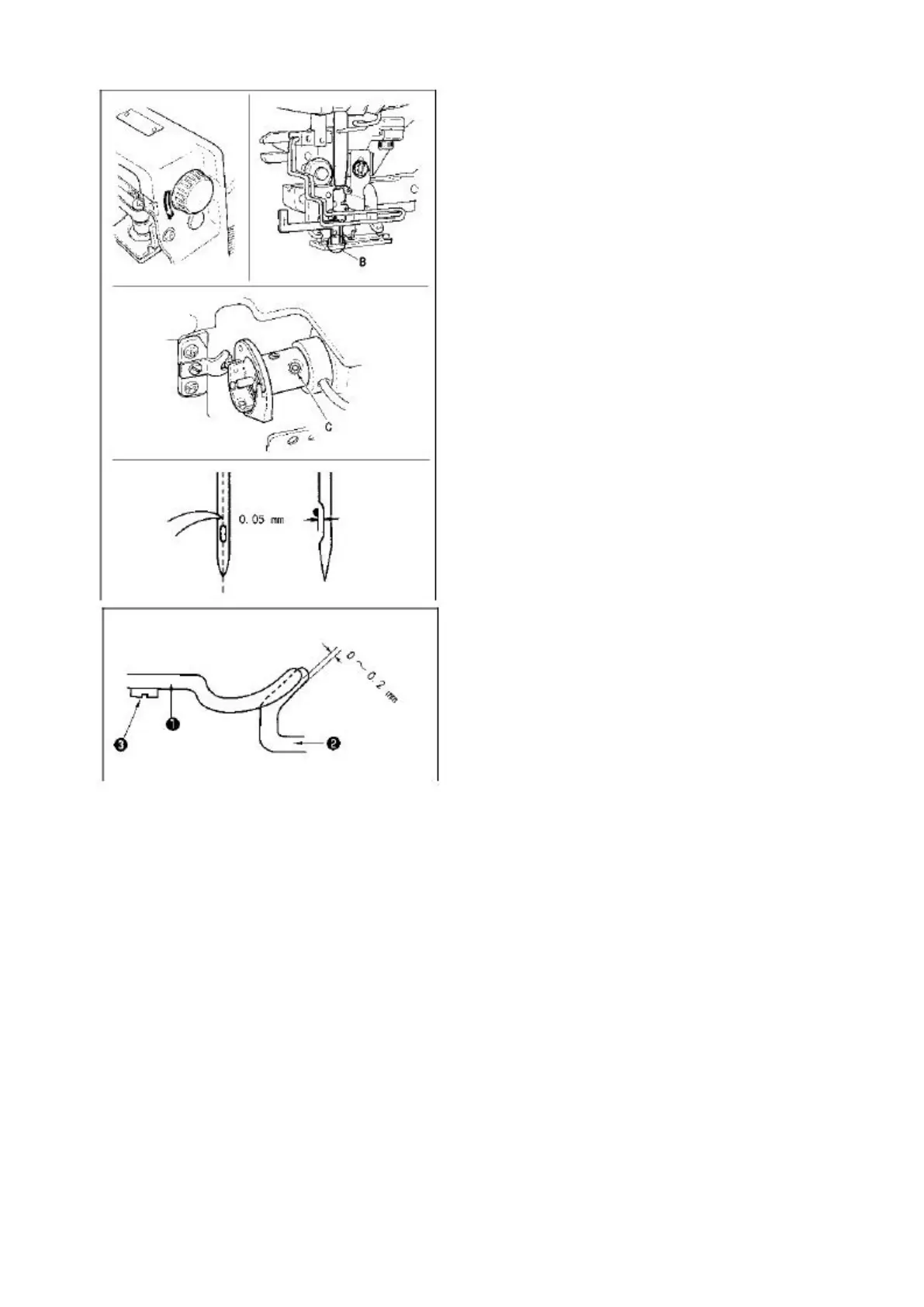

(2) Adjustment of needle-to-hook relation

1) Rotate hand driving wheel in accordance with

regular rotation direction to lift needle from the

lowest point.

2) Insert part [2] B of timing gauge into the gap

between the bottom end of needle bar and throat

plate, where the needle bar touches the timing

gauge.

3) Loosen setscrew C of the hook sleeve, and align

blade point of the sewing hook with the center of

needle hole.

Make a clearance of approx. 0.05 mm between the

needle and the blade point of the hook.

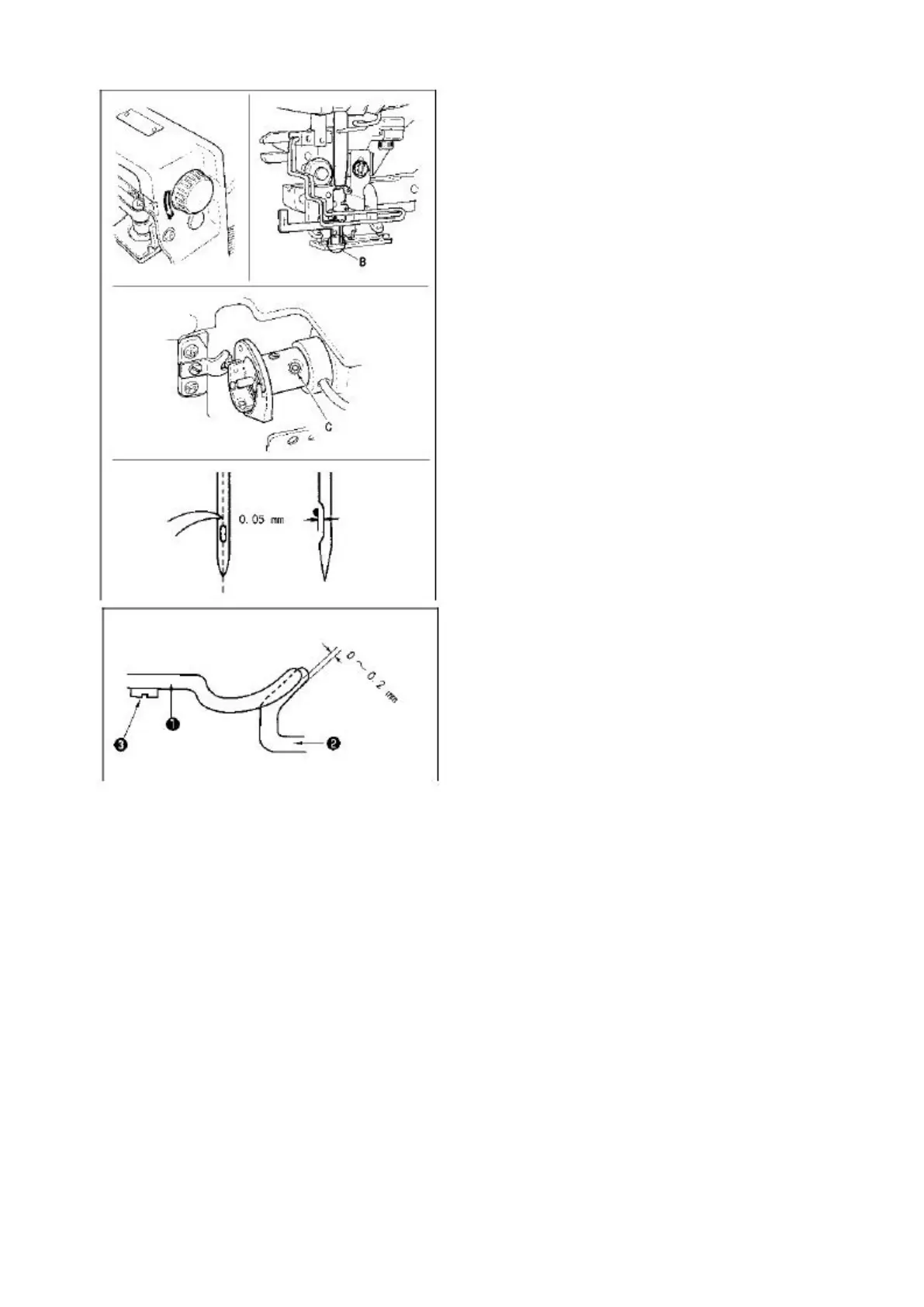

(3) Adjusting the inner hook stopper

Adjust with setscrew ③ so that the contact of the top

end of inner hook stopper ①

and the end face of inner

hook

②

is 0 to 0.2 mm.

Loading...

Loading...