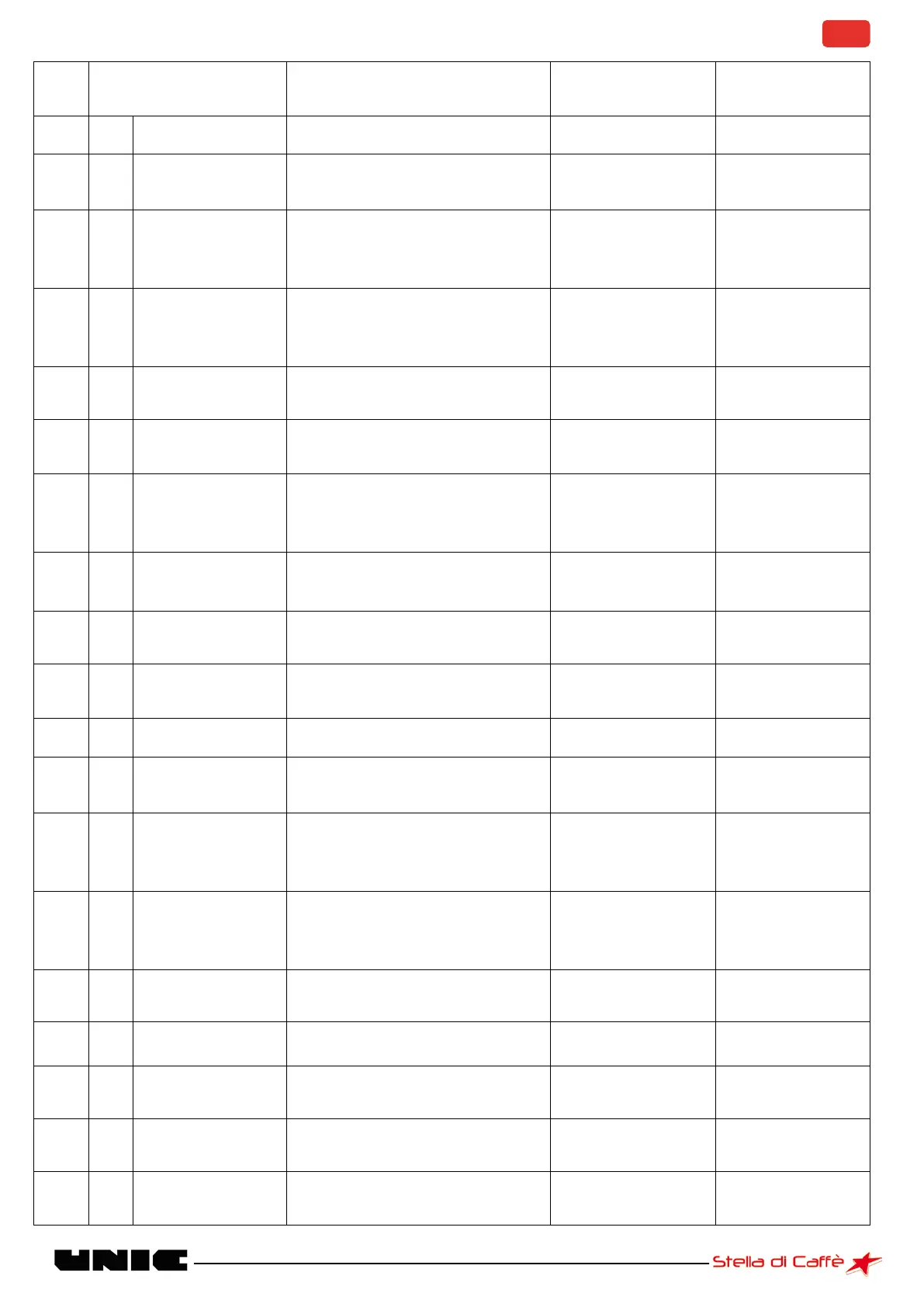

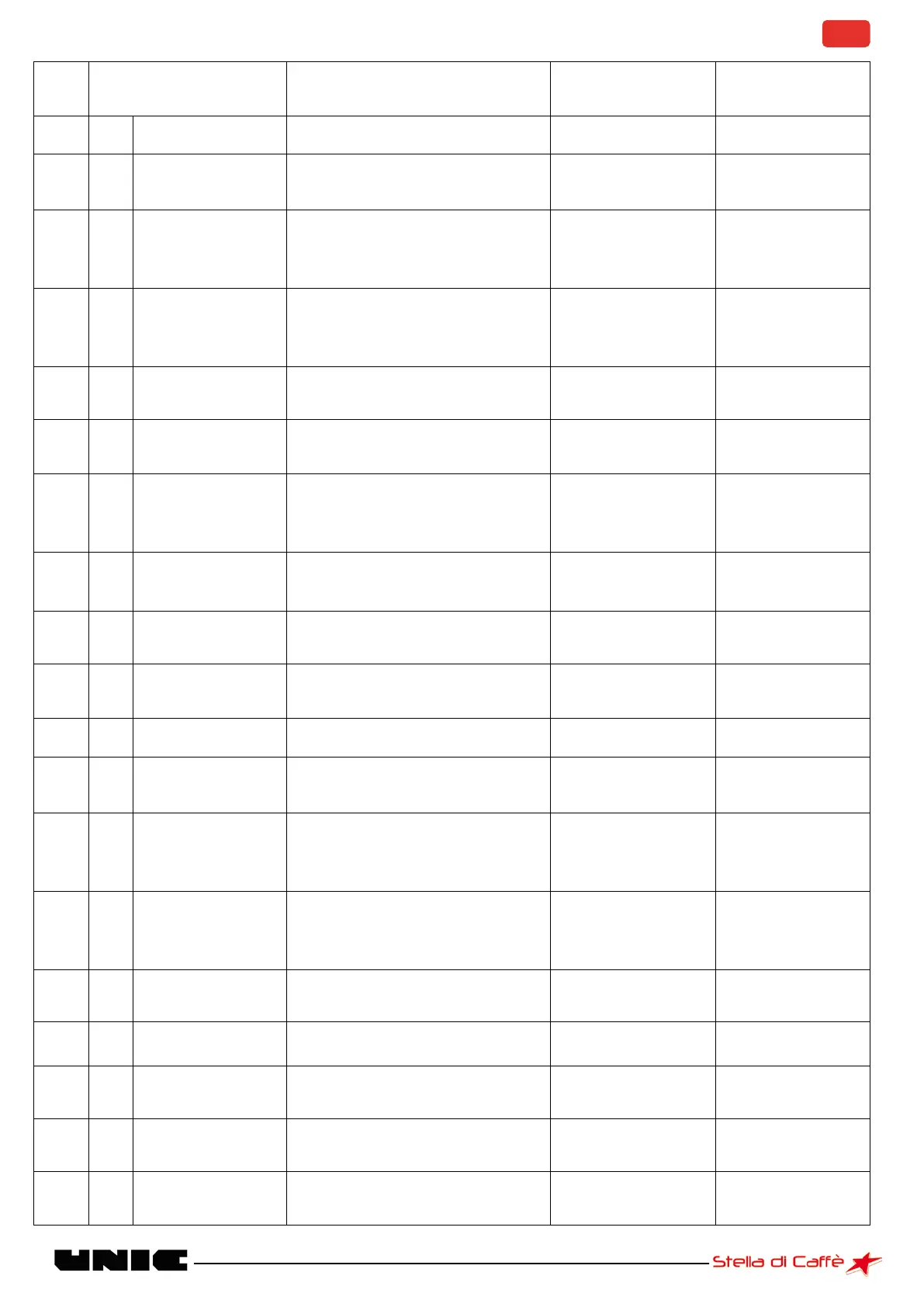

FAULT

CODE

COMPONENTS CONCERNED POSSIBLE CAUSES CONSEQUENCES

CONDITIONS FOR EXIT

OF THE SECURITY

14 DO1 Doser, GROUP 1

disconnected, absence of signal:

- Check the sensor and the wiring

Manual dosing alarm

eliminated

15 DO1 Doser GROUP 1

short circuit:

- Check the component and the wiring

Manual dosing alarm

Automatic if fault

eliminated

16 DO1 Doser, GROUP 1

Interruption in counting for more than 5

seconds:

- Check that the doser turbine turns freely

and check the wiring (bad contact)

Manual dosing alarm

Automatic if fault

eliminated

17 DO1 Doser, GROUP 1

Infusion time more than 110 seconds,

insufficient flow:

- Check the cleanliness of the hydraulic

circuit or increase the grain size.

Infusion cycle stops

Automatic if fault

eliminated

18 EH1

DOSAMAT sensor,

GROUP 1

disconnected, absence of signal:

- Check the sensor and the wiring

Manual start alarm

Automatic if fault

eliminated

19 EH1

DOSAMAT sensor,

GROUP 1

short circuit:

- Check the component and the wiring

Manual start alarm

Automatic if fault

eliminated

20 TS2

Safety thermostat on

GROUP 2

triggered following overheating

- Check the regulation circuit SR2 and the

thermostat TS2 (manual reset)

Heating stopped on Group

2 - Control box BG2 on

stand-by

Fault eliminated and

manual reset of TS2 and

machine reset

21 SR2

Thermostat sensor,

GROUP 2

disconnected, absence of signal:

- Check the sensor and the wiring

Heating stopped on Group

2 - Control box BG2 on

stand-by

Fault eliminated and

machine reset performed

22 SR2

Thermostat sensor,

GROUP 2

short circuit:

- Check the sensor and the wiring

2 - Control box BG2 on

stand-by

Fault eliminated and

machine reset performed

23 SR2

Thermostat sensor,

GROUP 2

Reading outside the authorised range:

- Check the programmed value and the

sensor.

2 - Control box BG2 on

stand-by

Automatic if fault

eliminated

24 DO2 Doser, GROUP 2

disconnected, absence of signal:

- Check the sensor and the wiring

Manual dosing alarm

eliminated

25 DO2 Doser, GROUP 2

short circuit:

- Check the component and the wiring

Manual dosing alarm

Automatic if fault

eliminated

26 DO2 Doser, GROUP 2

Interruption in counting for more than 5

seconds:

- Check that the Doser, turbine turns freely

and check the wiring (bad contact)

Dosage alarm or manual

stop

Automatic if fault

eliminated

27 DO2 Doser, GROUP 2

Infusion time more than 110 seconds,

insufficient flow:

- Check the cleanliness of the hydraulic

circuit or increase the grain size.

Infusion cycle stops

Automatic if fault

eliminated

28 EH2

DOSAMAT sensor,

GROUP 2

disconnected, absence of signal:

- Check the sensor and the wiring

Manual start alarm

Automatic if fault

eliminated

29 EH2

DOSAMAT sensor,

GROUP 2

short circuit:- Check the component and the

wiring

Manual start alarm

Automatic if fault

eliminated

30 TS3

Safety thermostat on

GROUP 3

triggered following overheating

- Check the regulation circuit SR3 and the

thermostat TS3 (manual reset)

Heating stopped Group 3

box BG3 on stand-by

manual reset of TS3 and

machine reset

31 SR3

Thermostat sensor,

GROUP 3

disconnected, absence of signal:

- Check the sensor and the wiring

Heating stopped Group 3

box BG3 on stand-by

Fault eliminated and

machine reset performed

32 SR3

Thermostat sensor,

GROUP 3

short circuit:

- Check the sensor and the wiring

Heating stopped Group 3

box BG3 on stand-by

Fault eliminated and

machine reset performed

Loading...

Loading...