DISASSEMBLY

Urschel Laboratories recommends that

spindle assemblies be returned to the fac-

tory for repair, see page 53. For customers

choosing to rebuild this assembly, the follow-

ing repair instructions must be followed pre-

cisely for successful repair. See “Spindle As-

sembly”, pages 110 & 111, for part number

information.

The following tools are recommended:

1. Vise

2. Arbor Press

3. Dial indicator

4. Surface plate

5. Bore gauge capable of measuring to .0001"

6. Micrometers (0-1" & 1-2")

7. Special tools available from Urschel Labo-

ratories, see “Tools”, page 82.

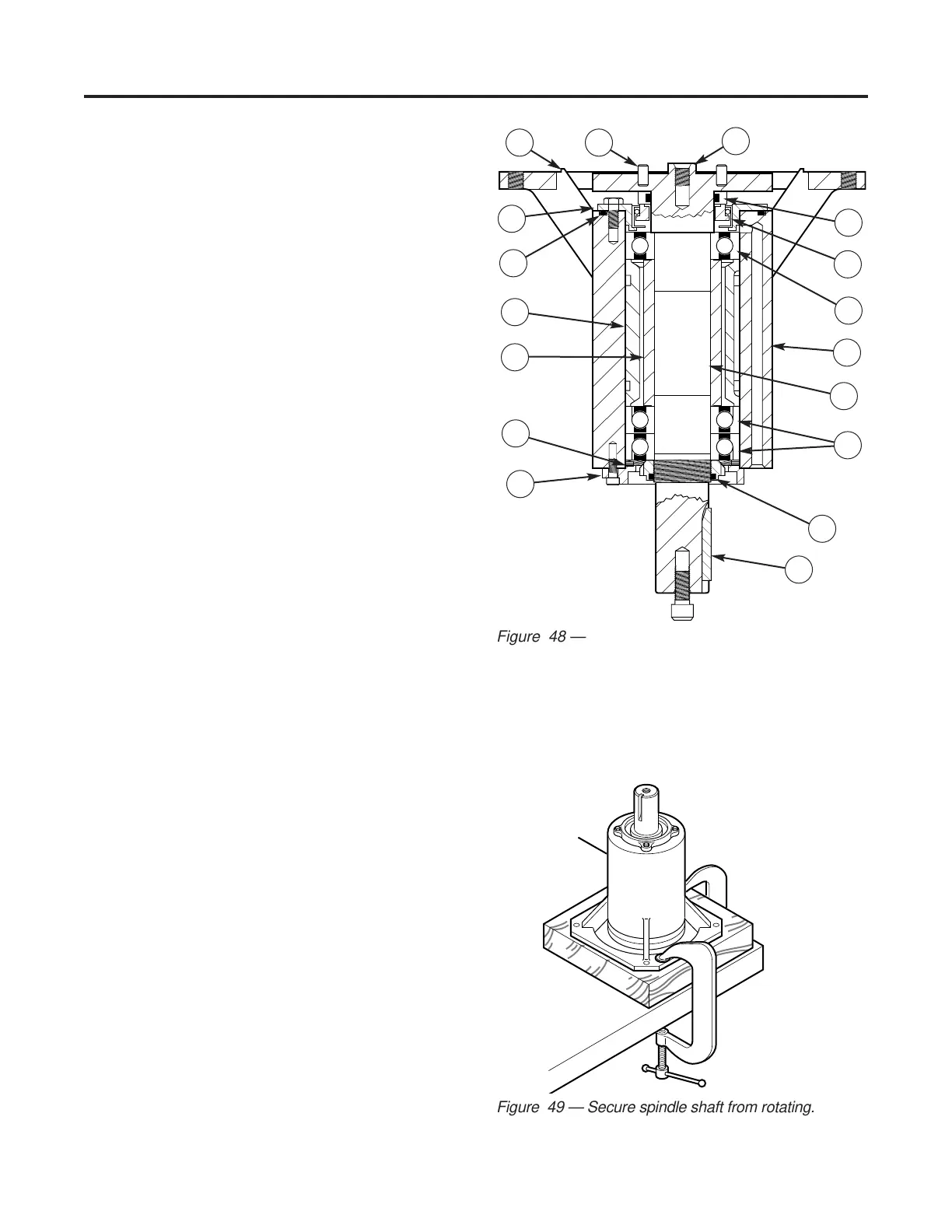

Refer to Figure 48 and proceed as follows:

1. Remove spindle from machine. See

page 54.

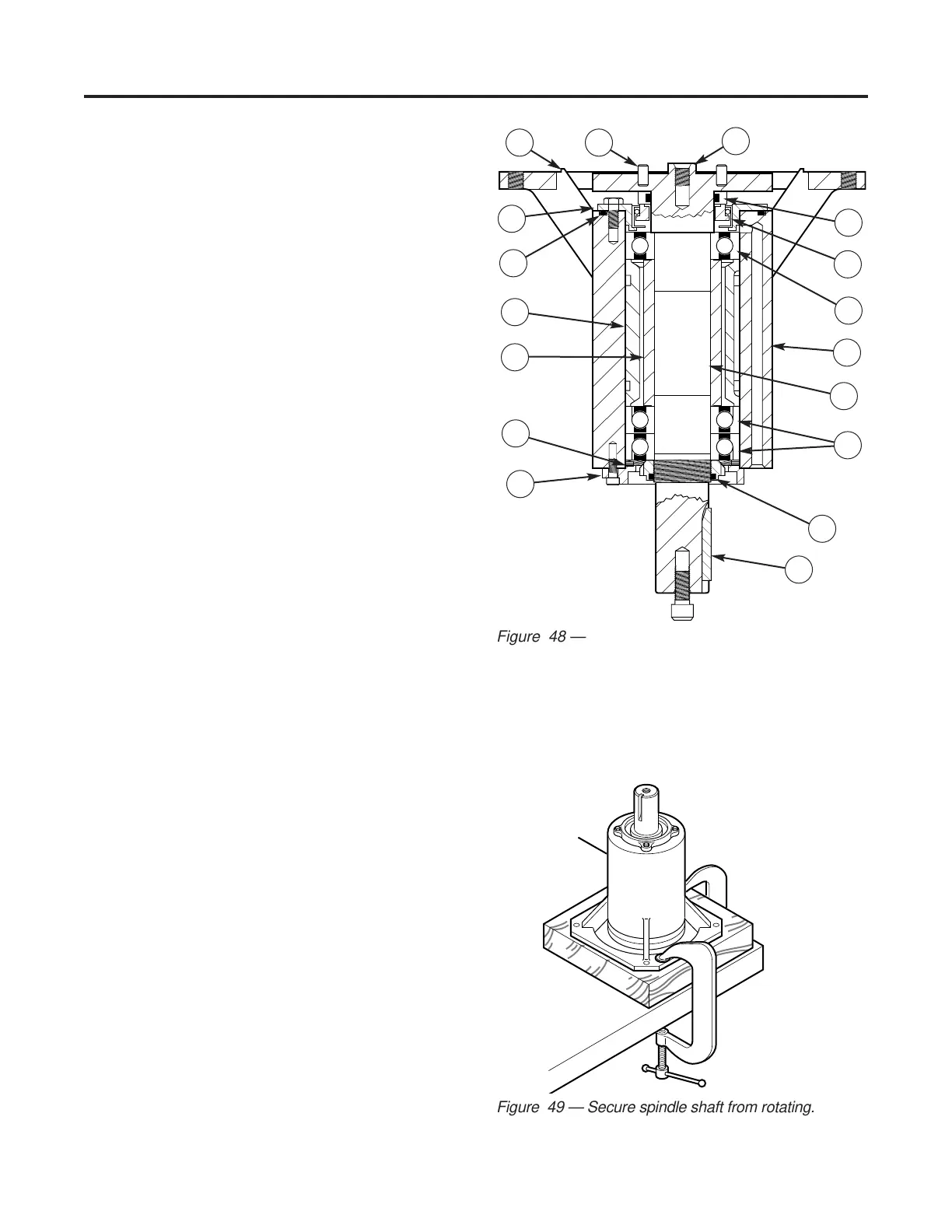

2. Secure shaft from rotating. Use a wood-

en block with drilled recesses for bearing

housing pilots, impeller shaft pilot and dow-

els (Figure 49). For impeller shafts without

dowels, place fasteners in impeller mount-

ing holes and drill recesses in wooden

block.

3. Remove lower bearing retainer and three

wavy spring washers.

MAINTENANCE

Spindle Assembly

56

Figure 49 — Secure spindle shaft from rotating.

Figure 48 — Spindle assembly. (1) Upper Bearing Re-

tainer, (2) “O” Ring, (3) Sleeve, (4) Bearing Spacer, (5)

Wavy Spring Washers, (6) Lower Bearing Retainer, (7)

Key, (8) Bearing Lock Nut, (9) Bearing - pair, (10) Im-

peller Shaft, (11) Bearing, (12) Seal, (13) Mating Ring,

(14) Bearing Housing, (15) Bearing Housing Pilot, (16)

Dowel, (17) Impeller Shaft Pilot

1

15 16

17

3

5

7

9

11

13

2

4

6

8

10

12

14

Loading...

Loading...