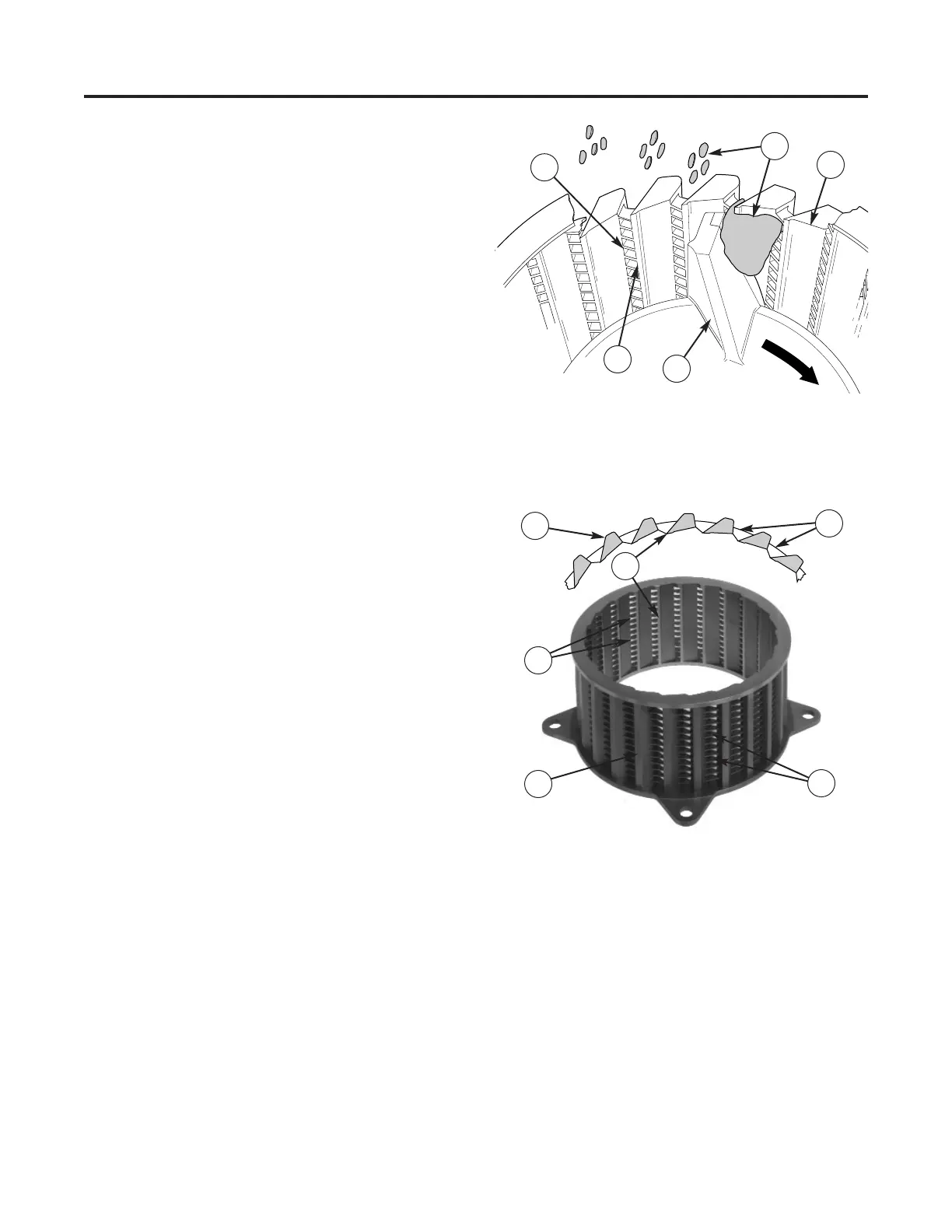

OPERATING PRINCIPLE

The impeller forces product against uniform-

ly spaced thin horizontal bars, or separators

(Figure 11). Small portions of product project-

ing into the spaces between the separators are

cut off into flakes by spaced columns of vertical

knives.These flakes fly outward and away from

the cutting head. The wall surfaces between

the vertical knives are relieved to eliminate rub-

bing friction that would produce heat. See

pages 112 thru 115 for a description and list of

cutting heads.

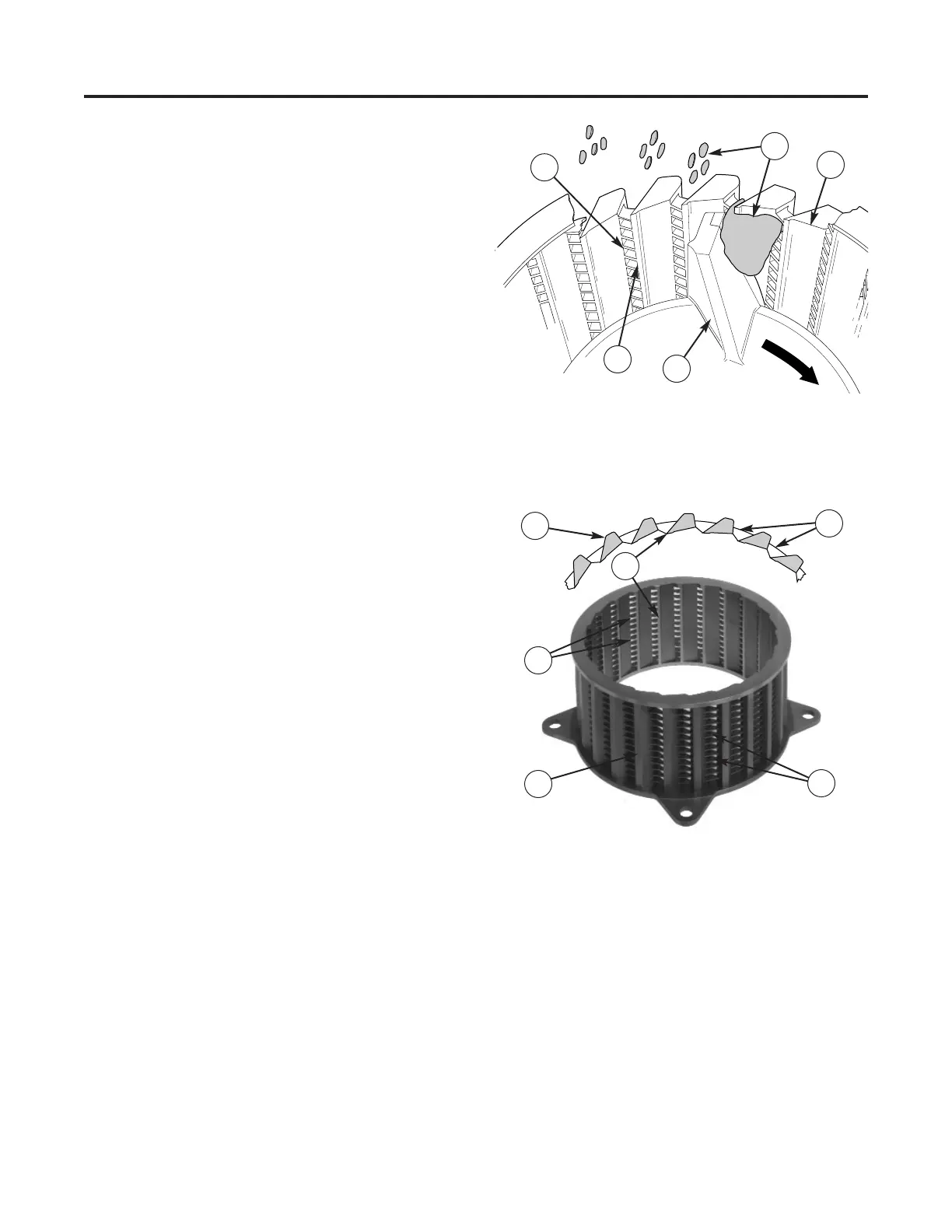

DESCRIPTION

The cutting head is a ring of vertical knives

and horizontal separators in a rigid, one piece

unit (Figure 12).Cutting heads are identified by

the Urschel 5-digit part number and a corre-

sponding description number.The description

number indicates the height of the head (2 or

3"), the pattern and number of columns, the

openings between and thickness of horizontal

separators, and the material of construction.

See page 64 for more detailed information.

Cutting heads are available in two different

styles, each made by a different method:

Urschalloy cutting heads are cast from one of

the toughest and most wear resistant alloys

known; fabricated cutting heads are made of

individual pieces of a tough special alloy stain-

less steel, assembled and silver brazed to-

gether. Each style of cutting head is available in

several different types (Figure 13, page 19.)

The type indicates the pattern and number of

columns, which contain the cutting edges.

Fewer columns will produce a thicker particle.

OPERATION

General Information, Cutting Heads

18

Figure 11 — Cutting head operation (1) Horizontal Sep-

arators, (2) Vertical Knives, (3) Impeller, (4) Product, (5)

Relieved Surface

1

2

4

5

3

3

Figure 12 — Typical cutting head and cross section (“K”

type Urschalloy) (1) Columns, (2) Horizontal Separators,

(3) Openings Between Separators, (4) Vertical Knives

4

2

2

1

1

Loading...

Loading...