A program is available from Urschel Labora-

tories that will allow customers to get up to

eight new blade edges from a single set of mi-

crocut blades (.084" thick blades only).The first

four edges are obtained using standard and

reverse slot blade holding rings. If the microcut

blades can be re-sharpened, a backing ring

for reduced width blades can be installed to

give four additional edges. See chart, page

125.The first four cutting edges are obtained

as follows:

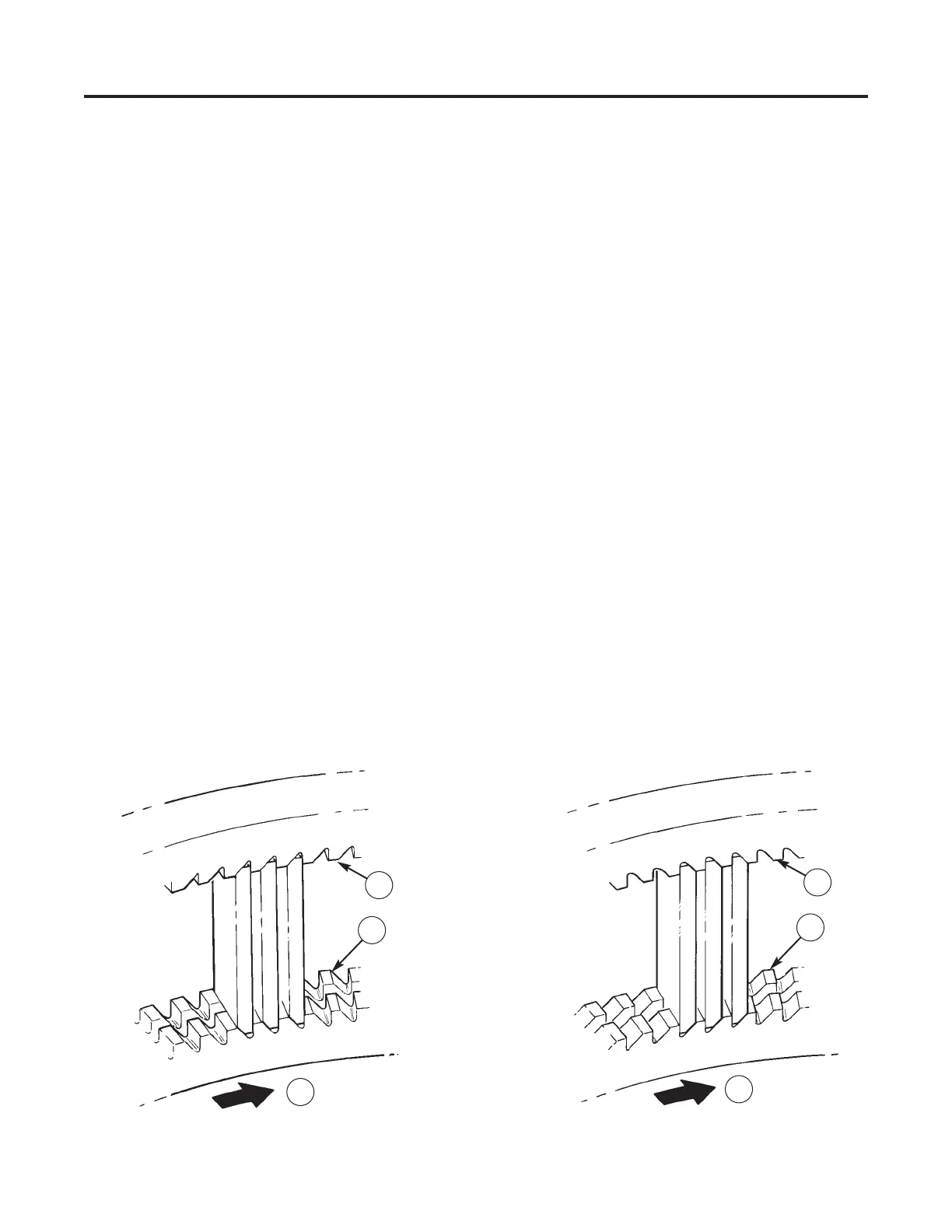

First set of cutting edges: a new set of

blades is installed in the microcut head. Stan-

dard blade holding rings are used (Figure 74).

Second set of cutting edges: each dull

blade is turned over to present all new cutting

edges

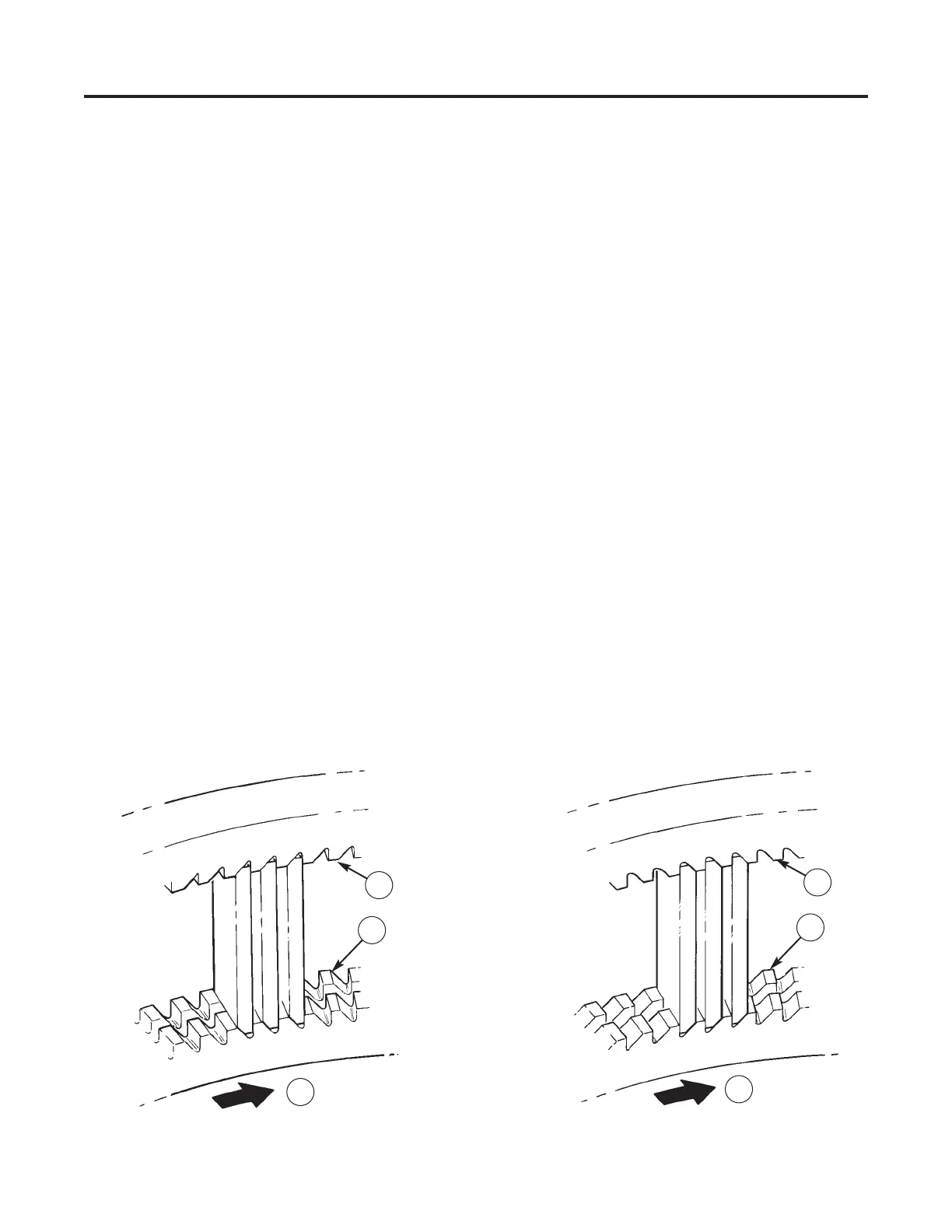

Third set of cutting edges: upper and

lower blade holding rings with reverse slots

(“R” suffix in description number, marked on

the ring) replace standard blade holding rings

in the microcut head.Blades are installed so as

to present new cutting edges (Figure 75).

Fourth set of cutting edges: blades are

turned over to present new cutting edges.

Microcut blades must be evaluated at this

point. Blades must be able to be re-sharpened

to a width of .335" (+.0000/-.0005"). Blades that

are severely worn or that have been damaged

by foreign material or from coming in contact

with the impeller generally cannot be re-ground

(Figure 76, page 71). To obtain the most eco-

nomical use, microcut blades should be in-

spected periodically and removed from the

head before they are worn beyond the point

that they can be re-ground. Blades can be re-

ground by a machine shop that uses diamond

faced grinding wheels, or by Urschel Labora-

tories, Inc., see page 71. Using reground

blades, four additional edges are obtained as

follows:

Fifth, sixth, seventh and eighth set of cut-

ting edges: backing ring for reduced width

blades replaces standard backing ring in the

microcut head.The resharpened blades are

used in the microcut head as outlined for the

original four edges.

MAINTENANCE

Microcut Blades

70

Figure 74 — Standard Blade Orientation. (1) Standard

Blade Holding Ring, (2) Impeller Rotation

Figure 75 — Reverse Blade Orientation. (1) R-Series

Blade Holding Ring (Reverse Slot), (2) Impeller

Rotation

1

1

2

1

1

2

Loading...

Loading...