RESHARPENING CUTTING HEADS

URSCHALLOY cutting heads may be

returned to the factory for resharpening, pro-

vided a certain amount of increased cutting

clearance is acceptable. With each grinding,

inside diameter is enlarged approximately

.005" (.127 mm). Heads can be sharpened

until amount of oversize reaches unaccept-

able limit; generally .030" (.762 mm). When

Urschalloy cutting heads are no longer

usable, they may be returned to the factory

for rebate. Cutting heads being returned for

sharpening or rebate should be clean and

free from foreign material. See page 49 for

ordering and returning parts information.

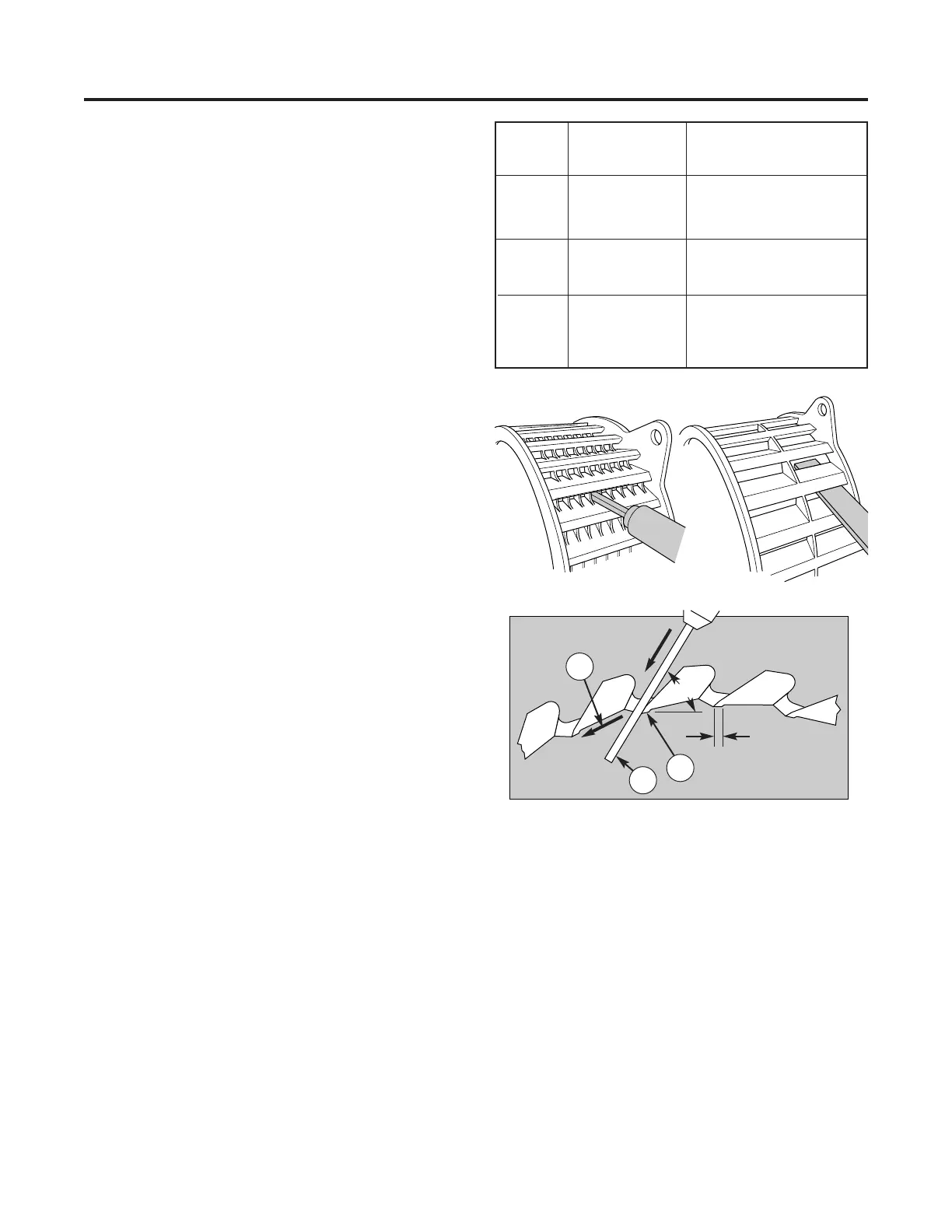

FABRICATED cutting heads with open-

ings between the horizontal separators of

0.150" to 1.500" (3.81 to 38.10 mm) may be

resharpened by filing. Cutting heads with

openings down to 0.100" (2.54 mm) should

be returned to the factory for resharpening;

openings below 0.100" (2.54 mm) cannot be

resharpened.

38

MAINTENANCE

Cutting Heads

File File Size Fabricated

Length (approximate) Cutting Head

4" 5/32" square K style, 0.150" & larger

J style, 0.150" — 0.240"

6" 1/4" square J style, 0.240" and up

8" 25/32 x 9/64" J style, 1.500"

flat

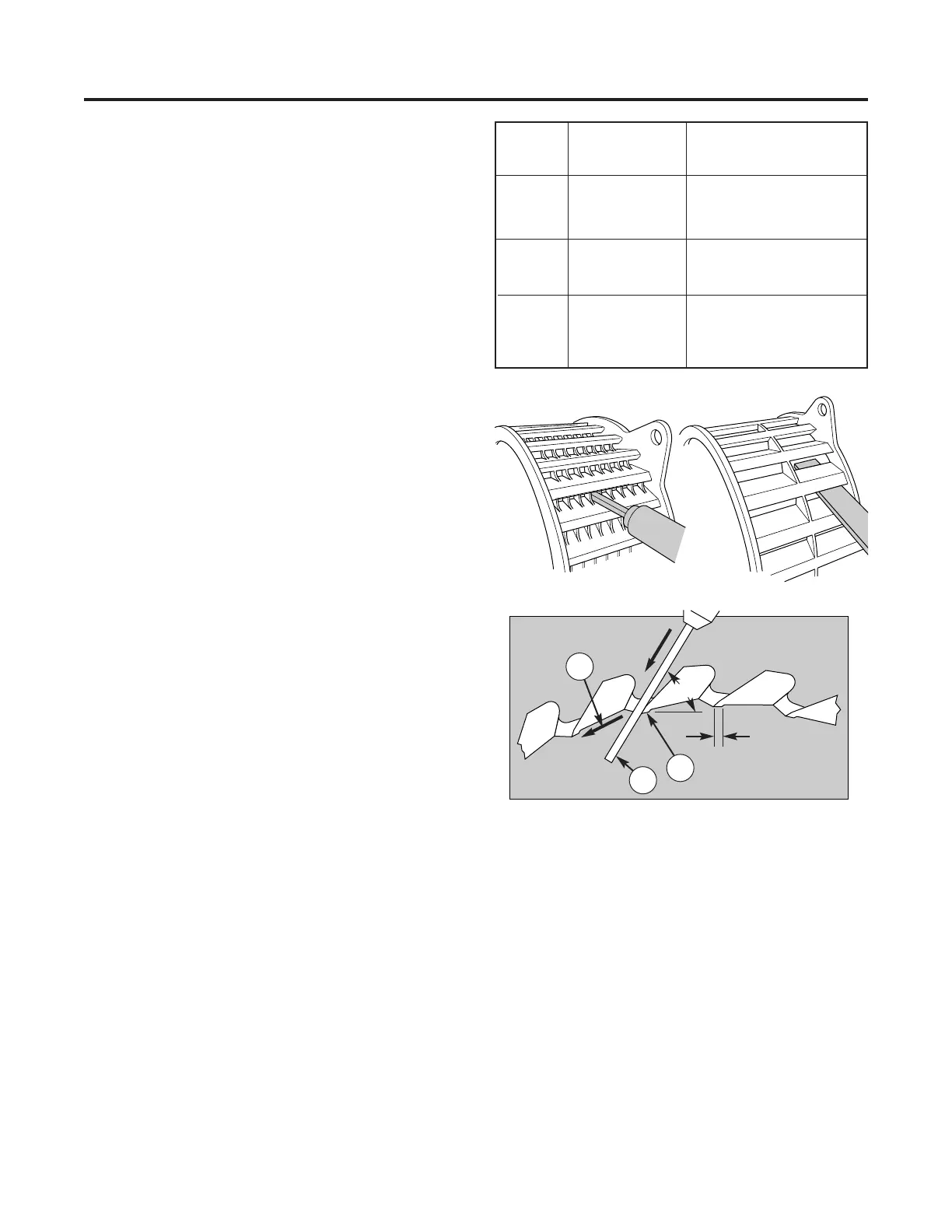

Figure 22 — Sharpening fabricated cutting heads.

(1) File, (2) Land, (3) Deburr in counterclockwise

direction inside cutting head using emery cloth

1/32" MIN.

45°

2

1

3

Loading...

Loading...